Germicide compounded from azoxystrobin, difenoconazole and cyproconazole and preparation method thereof

A technology of difenoconazole and compound fungicides, applied in the direction of fungicides, botanical equipment and methods, biocides, etc., can solve the problems of not obvious effects, resistance of germs, easy resistance, etc. Achieve the effect of reducing application cost, improving control effect and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: 40% difenoconazole · azoxystrobin · cyproconazole suspension concentrate, each component and weight percent are as follows:

[0043] Difenoconazole 12%

[0044] Azoxystrobin 20%

[0045] Cycloconazole 8%

[0046] Alkylphenol polyoxyethylene ether formaldehyde condensate 10%

[0047] Sodium lignosulfonate 8%

[0048] Sodium Lauryl Sulfate 3%

[0049] Magnesium Aluminum Silicate 2%

[0050] Epoxidized soybean oil 1%

[0051] Ethylene glycol 4%

[0052] Simethicone defoamer 0.5%

[0053] Deionized water make up to 100%

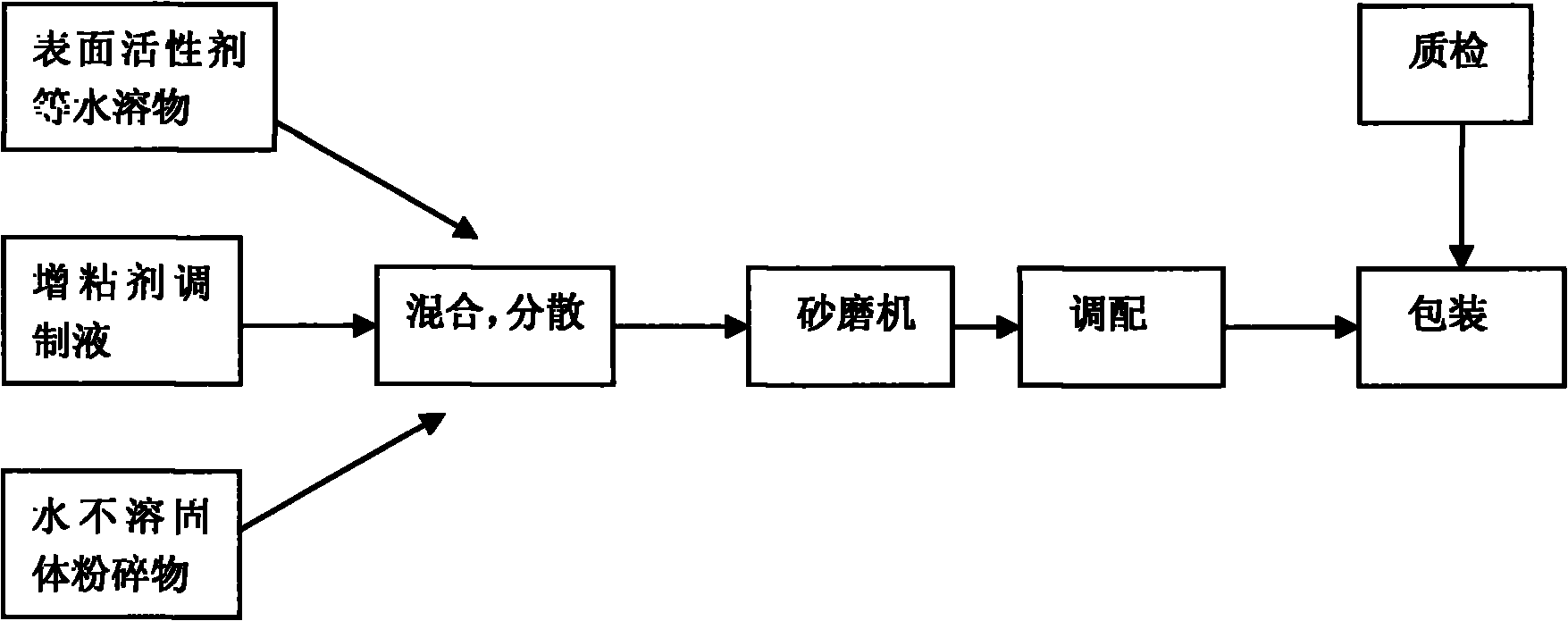

[0054] Preparation method: process the water-insoluble solid drug to above 325-800 mesh by mechanical or jet crushing method, and then mix it with the above-mentioned other ingredients such as emulsifier, antifreeze agent, tackifier and other water-soluble additives. Disperse or melt to prepare slurry, grind it 1-2 times in a horizontal sand mill, and finally adjust the technical indicators such as PH value, fluidity, wettability, etc....

Embodiment 2

[0055] Embodiment 2: 34% difenoconazole + azoxystrobin + cyproconazole suspension concentrate, each component and weight percentage are as follows:

[0056] Difenoconazole 10%

[0057] Azoxystrobin 18%

[0058] Cycloconazole 6%

[0059] Alkylphenol polyoxyethylene ether formaldehyde condensate 10%

[0060] Sodium lignosulfonate 8%

[0061] Sodium Lauryl Sulfate 3%

[0062] Magnesium Aluminum Silicate 2%

[0063] Epoxidized soybean oil 1%

[0064] Ethylene glycol 4%

[0065] Simethicone defoamer 0.5%

[0066] Deionized water make up to 100%

[0067] Preparation method: with embodiment 1

Embodiment 3

[0068] Example 3: 40% difenoconazole + azoxystrobin + cyclaconazole wettable powder, the components and weight percentages are as follows:

[0069] Difenoconazole 12%

[0070] Azoxystrobin 20%

[0071] Cycloconazole 8%

[0072] Alkylphenol polyoxyethylene ether formaldehyde condensate 10%

[0073] Sodium lignosulfonate 8%

[0074] Sodium Lauryl Sulfate 3%

[0075] Silica 2%

[0076] Epoxidized soybean oil 1%

[0077] Ethylene glycol 4%

[0078] Simethicone defoamer 0.5%

[0079] Diatomaceous earth fill up to 100%

[0080] Preparation method: first weigh azoxystrobin, difenoconazole, cyproconazole and solid dispersant, wetting agent, filler, etc. according to a certain proportion, mix them initially, and then crush them by airflow, and then mix them with Jingbai Stir the mixture of other liquid components well adsorbed by carbon black together, and then carry out sampling analysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com