Method for preparing In4Se3 thermoelectric compound powder

A compound and powder technology, which is applied in the field of preparation of In4Se3 thermoelectric compound powder, can solve the problems of high reaction temperature, poor repeatability, and long cycle, and achieve the effects of good repeatability, low pollution, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

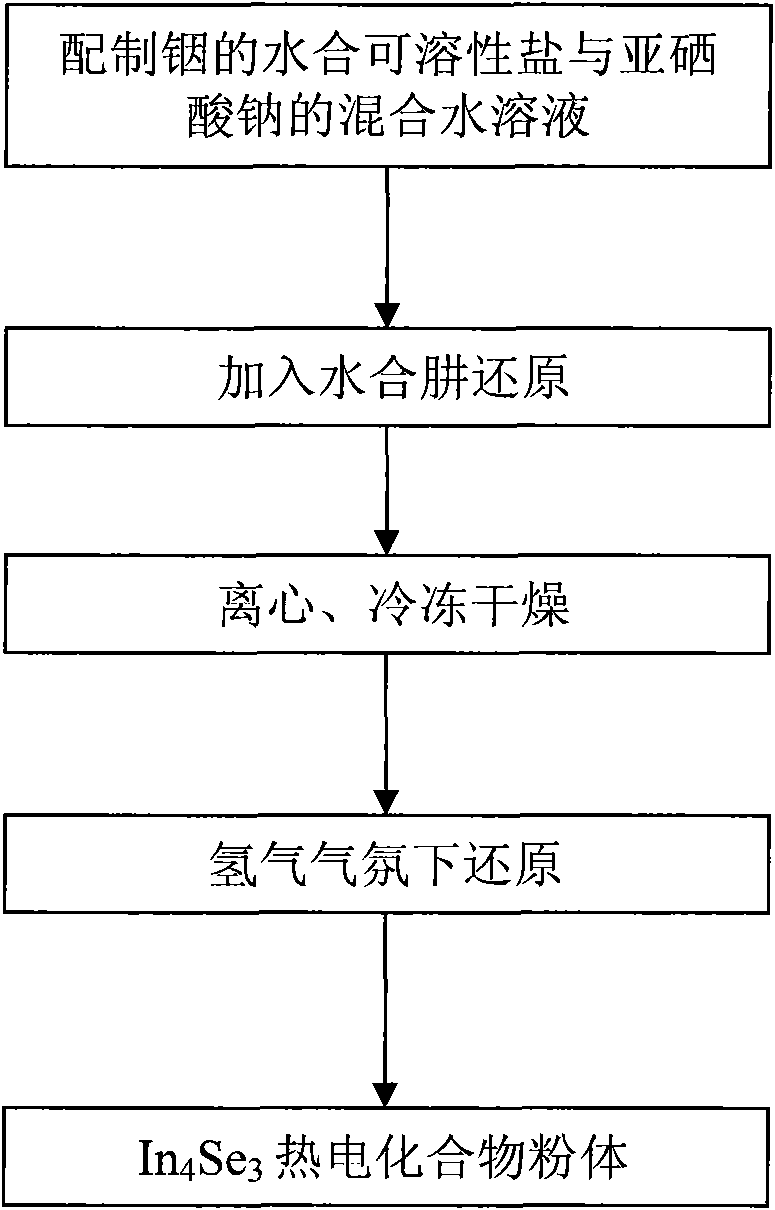

[0023] Such as figure 1 As shown, an In 4 Se 3 The preparation method of thermoelectric compound powder, it comprises the steps:

[0024] 1) Take a 400 ml beaker, weigh 0.5865 g of analytically pure indium chloride tetrahydrate, 0.2681 g of sodium selenite in turn, take 200 ml of deionized water, stir and mix evenly to obtain a mixed solution A;

[0025] 2) Add 1 mL of commercially available 85% hydrazine hydrate solution to the mixed solution A obtained in step 1) as a reducing agent, control the reaction temperature to 60° C., and perform ultrasonic reaction for 3 hours to obtain product B. The ultrasonic frequency is 42 KHz, and the power is 100-400W;

[0026] 3) Centrifuge the product B obtained in step 2) at a centrifugation rate of 8000r / min for 3min, and freeze-dry the precipitate obtained by centrifugation in a freeze-drying device at a freeze-drying temperature of -80°C and a drying time of 2h , to obtain dark red powder;

[0027] 4) The dark red powder obtained ...

Embodiment 2

[0030] Such as figure 1 As shown, an In 4 Se 3 The preparation method of thermoelectric compound powder, it comprises the steps:

[0031] 1) Take a 500 ml beaker, weigh 1.5276 grams of analytically pure indium nitrate 4.5 hydrate, 0.5188 grams of sodium selenite in turn, take 400 milliliters of deionized water, stir and mix evenly to obtain a mixed solution A;

[0032] 2) Add 10 mL of commercially available 85% hydrazine hydrate solution as a reducing agent to the mixed solution A obtained in step 1), control the reaction temperature to 80° C., and perform ultrasonic reaction for 12 hours to obtain product B. The ultrasonic frequency is 42 KHz and the power is 100-400W;

[0033] 3) Centrifuge the product B obtained in step 2) at a centrifugation rate of 10,000 r / min for 5 minutes, and freeze-dry the precipitate obtained by centrifugation in a freeze-drying device at a freeze-drying temperature of -85°C and a drying time of 6 hours. Obtain dark red powder;

[0034] 4) Put ...

Embodiment 3

[0037] Such as figure 1 As shown, an In 4 Se 3 The preparation method of thermoelectric compound powder, it comprises the steps:

[0038] 1) Take a 400 ml beaker, weigh 0.5865 g of analytically pure indium chloride tetrahydrate, 0.2594 g of sodium selenite in turn, take 200 ml of deionized water, stir and mix evenly to obtain a mixed solution A;

[0039] 2) Add 3 mL of commercially available 85% hydrazine hydrate solution to the mixed solution A obtained in step 1) as a reducing agent, control the reaction temperature to 50° C., and react under stirring for 10 hours to obtain product B;

[0040] 3) Centrifuge the product B obtained in step 2) at a centrifugation rate of 12000r / min for 3min, and freeze-dry the precipitate obtained by centrifugation in a freeze-drying device at a freeze-drying temperature of -75°C and a drying time of 2h , to obtain dark red powder;

[0041] 4) The dark red powder obtained in step 3) was reduced in an atmosphere furnace at 475°C for 2 hours ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com