Environment friendly microwave medium ceramic substrate

A microwave dielectric ceramic, environment-friendly technology, applied in the field of environment-friendly microwave dielectric ceramic substrate, to achieve the effects of reduced waste, efficient signal transmission, and reduced warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] An environment-friendly microwave dielectric ceramic substrate is made of ceramic microcrystalline powder, polytetrafluoroethylene powder (PTFE), polytetrafluoroethylene (PTFE) emulsion, glass fiber powder, liquid epoxy resin and PVA polyvinyl alcohol solution raw materials And trace flame retardant additive raw materials: brominated resin, antimony pentoxide (Sb 2 o 5 ), bismuth trioxide (Bi 2 o 3 ) directly mixed and stirred evenly to form a low-diluted lump; after initial rolling, initial drying, lamination, finishing rolling, double-sided or two-way continuous gluing, re-drying, double-sided or two-way continuous copper clad foil, cutting and high-pressure layer pressure; then vacuumize and solidify at low temperature to complete the preparation;

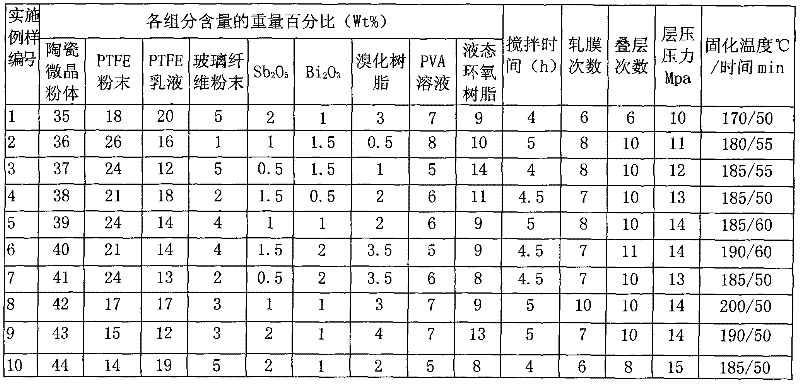

[0019] Table 1 provides the data of each embodiment raw material and production parameter;

[0020]

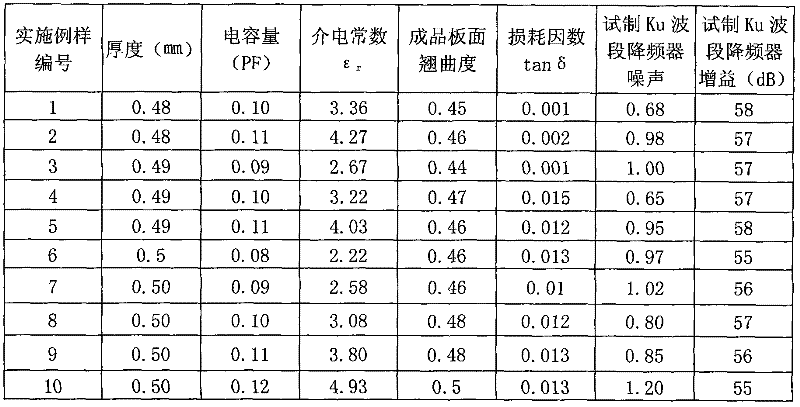

[0021] Table 2 provides the performance of each embodiment

[0022]

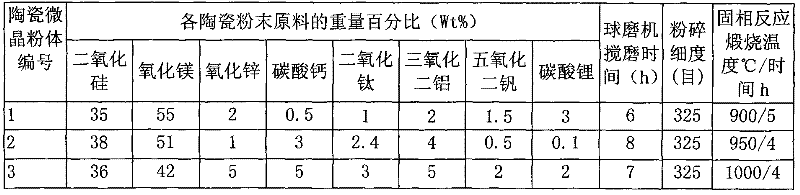

[0023] Table 3 also gives several prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com