Predation method of D-glucosamine hydrochloride

A technology of glucosamine hydrochloride and hydrochloric acid, which is applied in the field of medicine and chemical industry, can solve the problems of restricting the production and practical application of glucosamine hydrochloride products, long product production cycle, high hydrolysis temperature, etc., so as to shorten the hydrolysis reaction time and product cost Low, less environmental pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

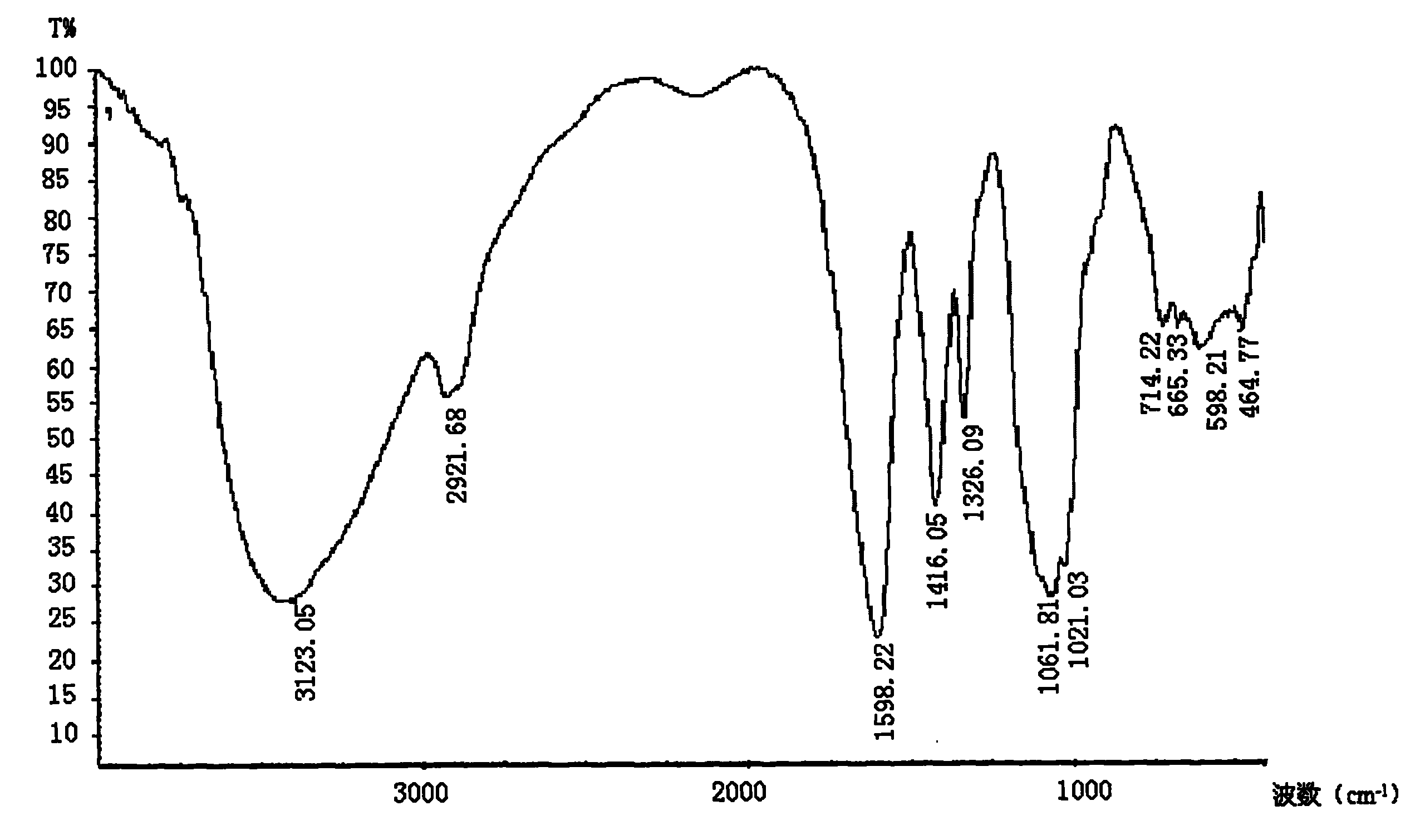

Image

Examples

Embodiment approach 1

[0019] Get 200g of dried citric acid mycelium residue containing Aspergillus niger (Mucar rouxii) (from Jiangsu Yixing Xielian Biochemical Co., Ltd.) raw material in a distillation three-necked flask, add 12mol / L hydrochloric acid (HCL) 310ml, heat to 85 ℃ and keep warm for 30min, add dropwise 30% hydrogen peroxide (H 2 o 2 ) 7.5ml, under microwave conditions (pressure 0.3MPa, use 80% of total power 2kw, time 300s, XT-9900 intelligent microwave digestion instrument) to continue hydrolysis for 1.5h;

[0020] Filtrate the reaction mixture while it is hot, concentrate the filtrate under reduced pressure at 80°C to 20% of the original volume, and then cool to room temperature. After filtration, 12 grams of crude crystals are obtained. The crude product is dissolved in 36 grams of water, and 6g of activated carbon is added and incubated at 70°C for 30 minutes. Suction filtration, concentration under reduced pressure (temperature<70°C) to 20-30% of the original volume, cooling and ...

Embodiment approach 2

[0023] Take 500 g of dried citric acid mycelium residue containing Aspergillus niger (Mucar rouxii) (from Jiangsu Yixing Xielian Biochemical Co., Ltd.) raw material in a three-neck distillation flask, add 775 ml of 12mol hydrochloric acid (HCL), heat to 90 ° C and Keep warm for 1h, add dropwise 30% hydrogen peroxide (H 2 o 2 ) 15ml, under microwave conditions (pressure 0.4MPa, use 70% of the total power 2kw, time 300s) to continue hydrolysis for 1h;

[0024] Filter the reaction mixture while it is hot, concentrate the filtrate under reduced pressure at 80°C to 20% of the original volume, and then cool to room temperature. After filtration, 29 grams of crude crystals are obtained. The crude product is dissolved in 100 grams of water, and 20 g of activated carbon is added at 70° C. for 30 minutes. , suction filtration,

[0025] 8. He Yancai, Xu Qingqing, Xu Yanhong, Zhuang Yongjin. Extraction of chitin and chitosan from Aspergillus niger [J]. Biotechnology, 2000, (4).

[0026...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com