Controlled release preparation

A controlled-release preparation and cyclodextrin technology, which is applied in the direction of pill delivery, medical preparations containing active ingredients, coatings, etc., can solve the health hazards, unsafe, long-term problems of operators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

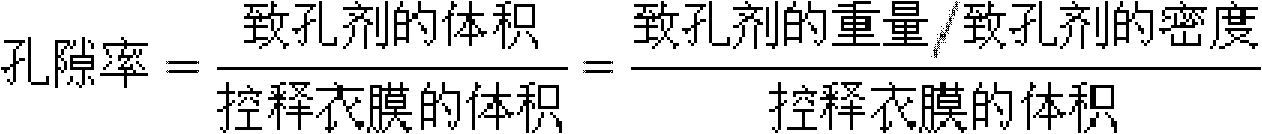

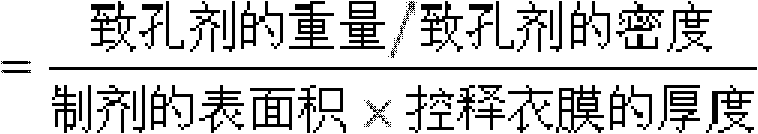

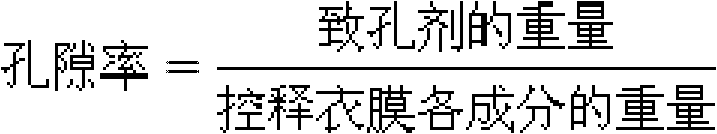

[0135] The invention relates to a method for preparing a controlled-release preparation coated with a controlled-release film, especially a zero-order release controlled-release preparation. Each basic step in the preparation method of the controlled-release preparation is described in detail below.

[0136] 1), preparing a core material containing at least one drug

[0137] The method of preparing the core material containing at least one drug is not particularly limited. Usually the preparation method is that the pharmaceutically active substance, and / or non-pharmaceutical auxiliaries and other ingredients are passed through the direct extrusion method, the extrusion method of dry, wet or sintered granules, extrusion and subsequent rounding, wet or dry granulation or Pelletizing directly (for example on discs) or bonding of powder (powder layer) to active substance-free spheres (granules) or active substance-containing granules, or further tableting in a certain way, eg by ...

Embodiment 1

[0160] 1. Preparation of samples

[0161] 1), preparation of tablet core:

[0162]

[0163]

[0164] Diltiazem, fatty acid, citric acid, sodium chloride, lactose and povidone were mixed, and granulated with absolute ethanol solution; the wet granulated material was forced through an 18-mesh sieve and dried for 24 hours; after granulation, After mixing with stearic acid and magnesium stearate, it is molded into a tablet core of 420 mg, and the tablet is compressed with a 7 / 16 "deep concave die.

[0165] 2), the tablet core is coated according to the following prescription and process:

[0166] Coating Solution Prescription:

[0167]

[0168] The solids content of the aqueous dispersion was 16% by weight. The tablet cores were coated on a Hicoater / Fruend coater. Coating condition parameters: spray rate, 1ml / min; inlet temperature, 70-80°C; outlet temperature, 40-42°C; tablet core temperature, 40°C; coating layer thickness, 250-350μm.

[0169] 4), healing controlled...

Embodiment 2

[0174] The sulfobutyl (ether)-β-cyclodextrin (DS=1.30~1.45) in the coating solution prescription of Example 1 is replaced by hydroxybutenyl ether cyclodextrin (DS=2.43~2.56) to prepare Example 2 , and then changed to hydroxybutenyl ether cyclodextrin (DS=0.23~0.36) and urea to prepare comparative samples 3 and 4, and the others were all in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com