System and method for extracting microprotein from sludge through hydrolysis

A microbial and protein technology, which is applied in the preparation method of peptides, chemical instruments and methods, organic chemistry, etc., can solve the problems of long evaporation time, corrosion of land, air pollution, etc., and achieve excellent product performance, high production efficiency, and extraction high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

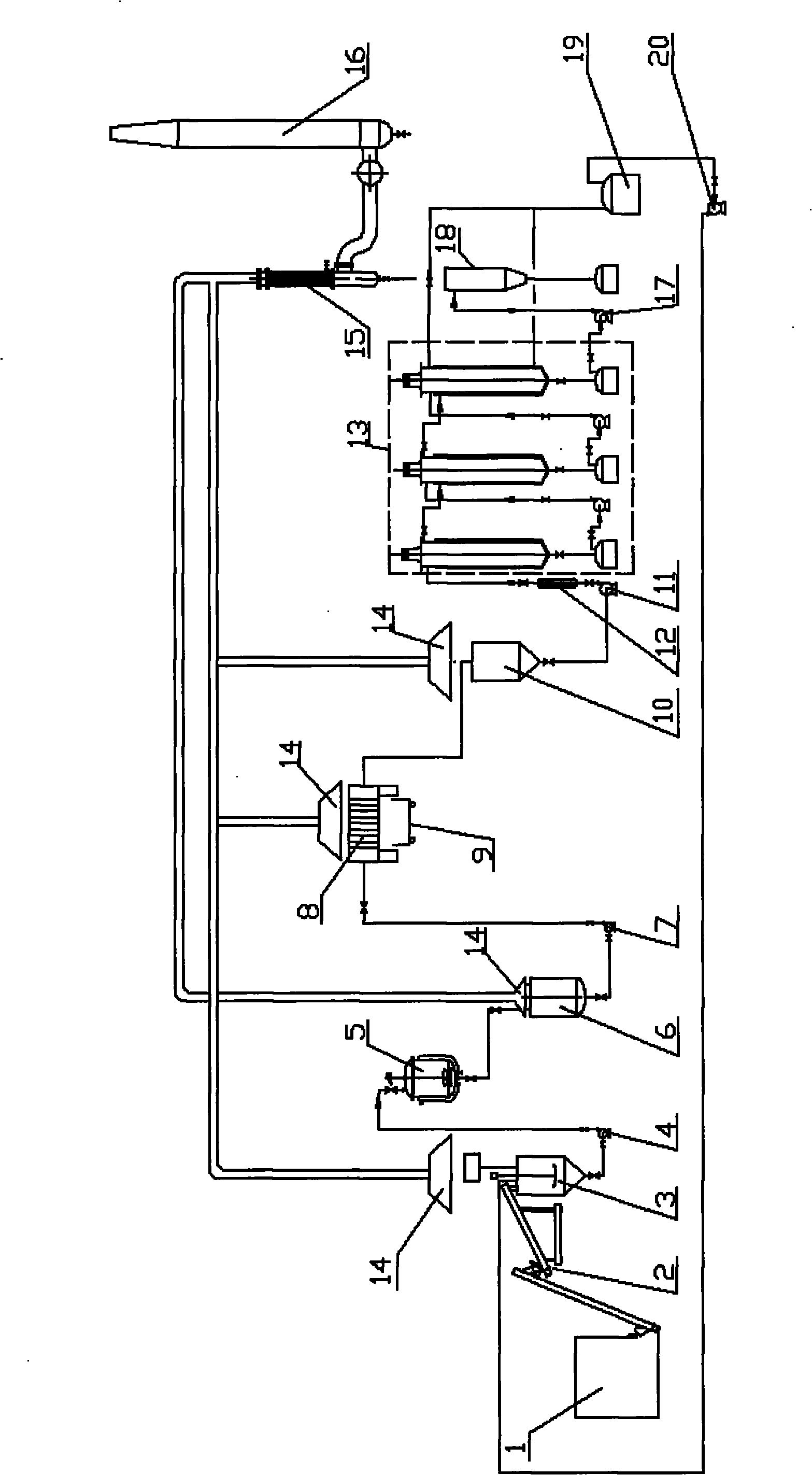

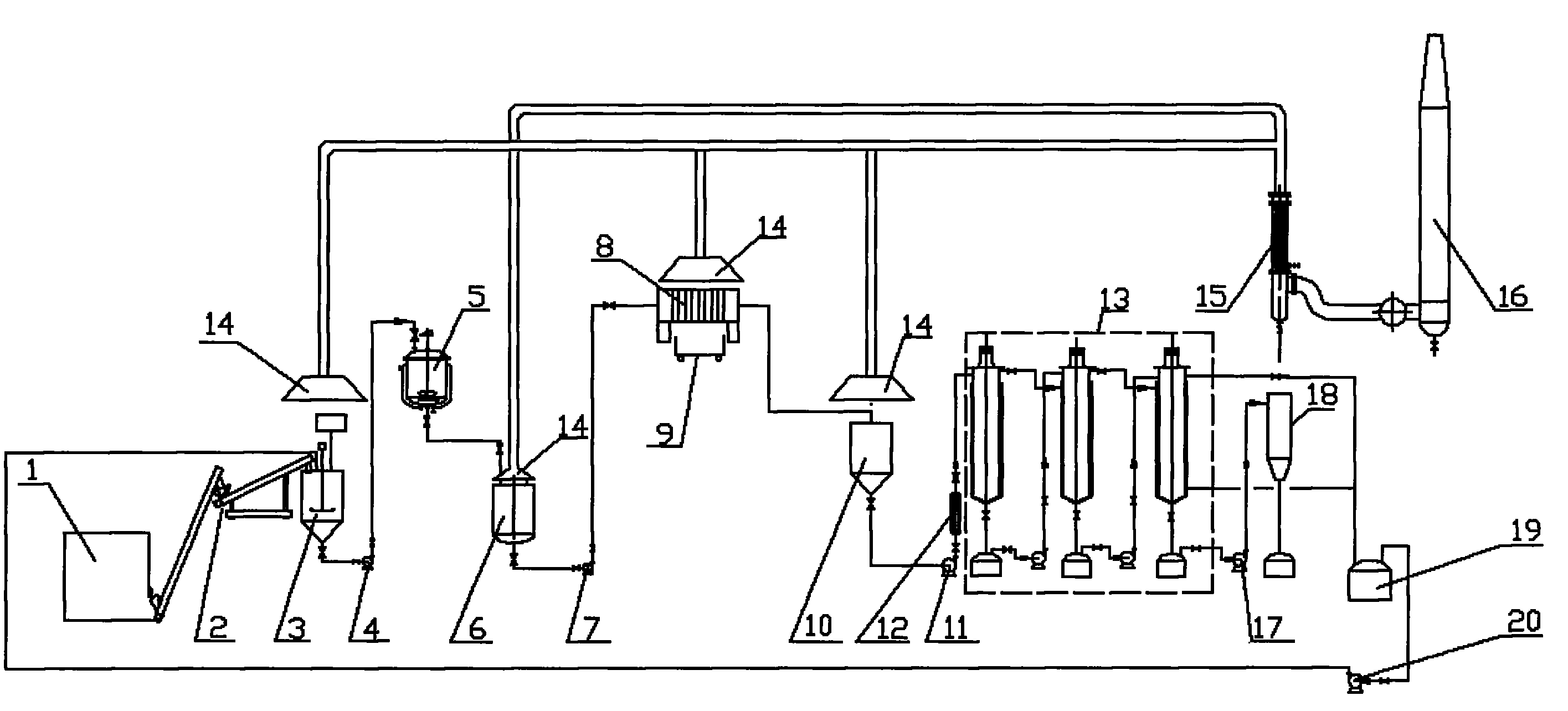

[0033] A system for sludge hydrolysis to extract microbial proteins, including a sludge storage device 1, a sludge conveying device 2, a mixing device 3, a hydrolysis reaction device 5, a flash evaporation device 6, a solid-liquid separation device 8, a residue collection and conveying device 9, and a filtrate Collection device 10 , preheating device 12 , evaporative concentration device 13 , drying device 18 , waste gas collection device 14 , waste gas treatment device 15 , waste gas discharge device 16 , process water recovery device 19 .

[0034] The outlet end of the sludge storage device 1 is connected to the feed port of the mixing device 3 through the sludge conveying device 2, and the discharge port of the mixing device 3 is connected to the feed port of the hydrolysis reaction device 5 through the pipeline through the pump 4, and the hydrolysis The feed port of the reaction device 5 is connected with the feed port of the flash device 6 by a pipeline, and the discharge ...

Embodiment 2

[0038] A system for sludge hydrolysis to extract microbial proteins, including a sludge storage device 1, a sludge conveying device 2, a mixing device 3, a hydrolysis reaction device 5, a flash evaporation device 6, a solid-liquid separation device 8, a residue collection and conveying device 9, and a filtrate Collection device 10 , preheating device 12 , evaporative concentration device 13 , drying device 18 , waste gas collection device 14 , waste gas treatment device 15 , waste gas discharge device 16 , process water recovery device 19 .

[0039] The outlet end of the sludge storage device 1 is connected to the feed port of the mixing device 3 through the sludge conveying device 2, and the discharge port of the mixing device 3 is connected to the feed port of the hydrolysis reaction device 5 through the pipeline through the pump 4, and the hydrolysis The feed port of the reaction device 5 is connected with the feed port of the flash device 6 by a pipeline, and the discharge ...

Embodiment 3

[0043] A system for sludge hydrolysis to extract microbial proteins, including a sludge storage device 1, a sludge conveying device 2, a mixing device 3, a hydrolysis reaction device 5, a flash evaporation device 6, a solid-liquid separation device 8, a residue collection and conveying device 9, and a filtrate Collection device 10 , preheating device 12 , evaporative concentration device 13 , drying device 18 , waste gas collection device 14 , waste gas treatment device 15 , waste gas discharge device 16 , process water recovery device 19 .

[0044] The outlet end of the sludge storage device 1 is connected to the feed port of the mixing device 3 through the sludge conveying device 2, and the discharge port of the mixing device 3 is connected to the feed port of the hydrolysis reaction device 5 through the pipeline through the pump 4, and the hydrolysis The feed port of the reaction device 5 is connected with the feed port of the flash device 6 by a pipeline, and the discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com