Method for preparing nitrogen-doped titanium dioxide nanotube array

A technology of nanotube array and titanium dioxide, which is applied in the direction of coating, surface reaction electrolytic coating, electrolytic coating, etc., can solve the problem of low photocatalytic efficiency, achieve high heat utilization rate, mature process, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

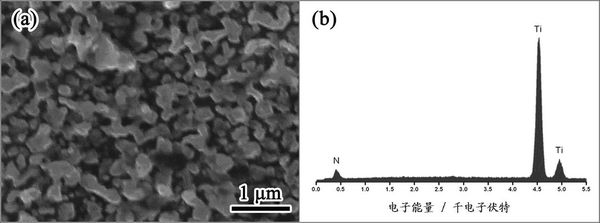

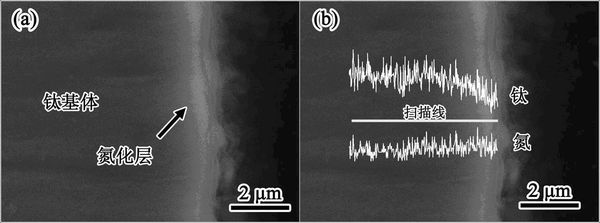

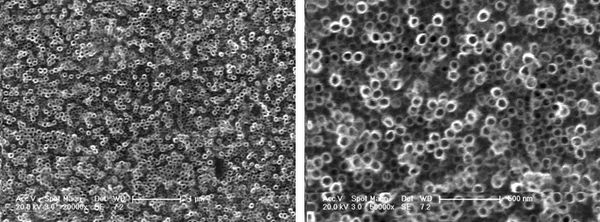

[0038] Example 1: Industrial pure titanium is pretreated by grinding, polishing, ultrasonic cleaning and drying, etc., and then put it into the LD-70 ion nitriding furnace filled with dilute ammonia gas (the furnace chamber maintains negative pressure), With the inner wall of the furnace as the anode and the sample as the cathode, high voltage is applied to generate glow discharge, the nitriding temperature is 500 °C, and the nitriding time is 15 hours. After the ion nitriding process is completed, the sample is cooled to room temperature with the furnace, and then the sample is taken out; Measure 1.74 ml of hydrofluoric acid (40 vol.%), add ethylene glycol to 200 ml, and prepare 200 ml of HF / ethylene glycol anodic oxidation electrolyte; the nitrided metal titanium is used as the anode, and the graphite sheet is used as the anode. The cathode was anodized for 3 hours with an external DC voltage of 15 V, and then the obtained sample was calcined in air at 500 °C for 3 hours.

...

Embodiment 2

[0040] Example 2: The titanium alloy is pretreated by grinding, polishing, ultrasonic cleaning and drying in sequence, and then it is put into an LD-70 ion nitriding furnace filled with dilute ammonia gas (the furnace chamber maintains negative pressure), so as to The inner wall of the furnace is the anode, and the sample is used as the cathode. High voltage is applied to generate glow discharge. The nitriding temperature is 700 °C, and the nitriding time is 20 hours. After the ion nitriding process is completed, the sample is cooled to room temperature with the furnace, and then the sample is taken out; Take 2.61 ml of hydrofluoric acid (40 vol.%), add ethylene glycol to 200 ml, and prepare 200 ml of HF / ethylene glycol anodic oxidation electrolyte; the nitrided metal titanium is used as the anode, and the graphite sheet is used as the cathode , applied a DC voltage of 30 V, anodized for 4 hours, and then the obtained samples were calcined in air at 400 °C for 6 hours.

[0041...

Embodiment 3

[0042] Example 3: Put commercially pure titanium (TA2) through pretreatments such as grinding, polishing, ultrasonic cleaning and drying in sequence, and then put it into an LD-70 ion nitriding furnace filled with dilute ammonia gas (the furnace chamber maintains negative pressure), with the inner wall of the furnace as the anode and the sample as the cathode, high voltage is applied to generate glow discharge, the nitriding temperature is 600 °C, and the nitriding time is 5 hours. After the ion nitriding process is completed, the sample is cooled to room temperature with the furnace, and then Take out the sample; measure 3.48 ml hydrofluoric acid (40 vol.%), add ethylene glycol to 200 ml, and prepare 200 ml HF / ethylene glycol anodic oxidation electrolyte; use the nitriding-treated titanium metal as the anode, The graphite sheet was used as the cathode, and a 25 V DC voltage was applied, anodized for 2 hours, and then the obtained sample was calcined in air at 600 °C for 4 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com