Biological deodorization and discoloration method for proteins from silk-reeling silkworm chrysalises

A technology for biological deodorization and silkworm chrysalis protein, which is applied to the protein composition of microorganisms, the protein composition of waste, and the protein composition of plant materials, etc., can solve the problems of secondary protein pollution, incomplete deodorization, complicated procedures, etc. The effect of digestion and absorption rate, reasonable amino acid composition and simple technical process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The biological deodorization and decolorization method of the silkworm chrysalis protein of the present invention is further specifically described below by examples:

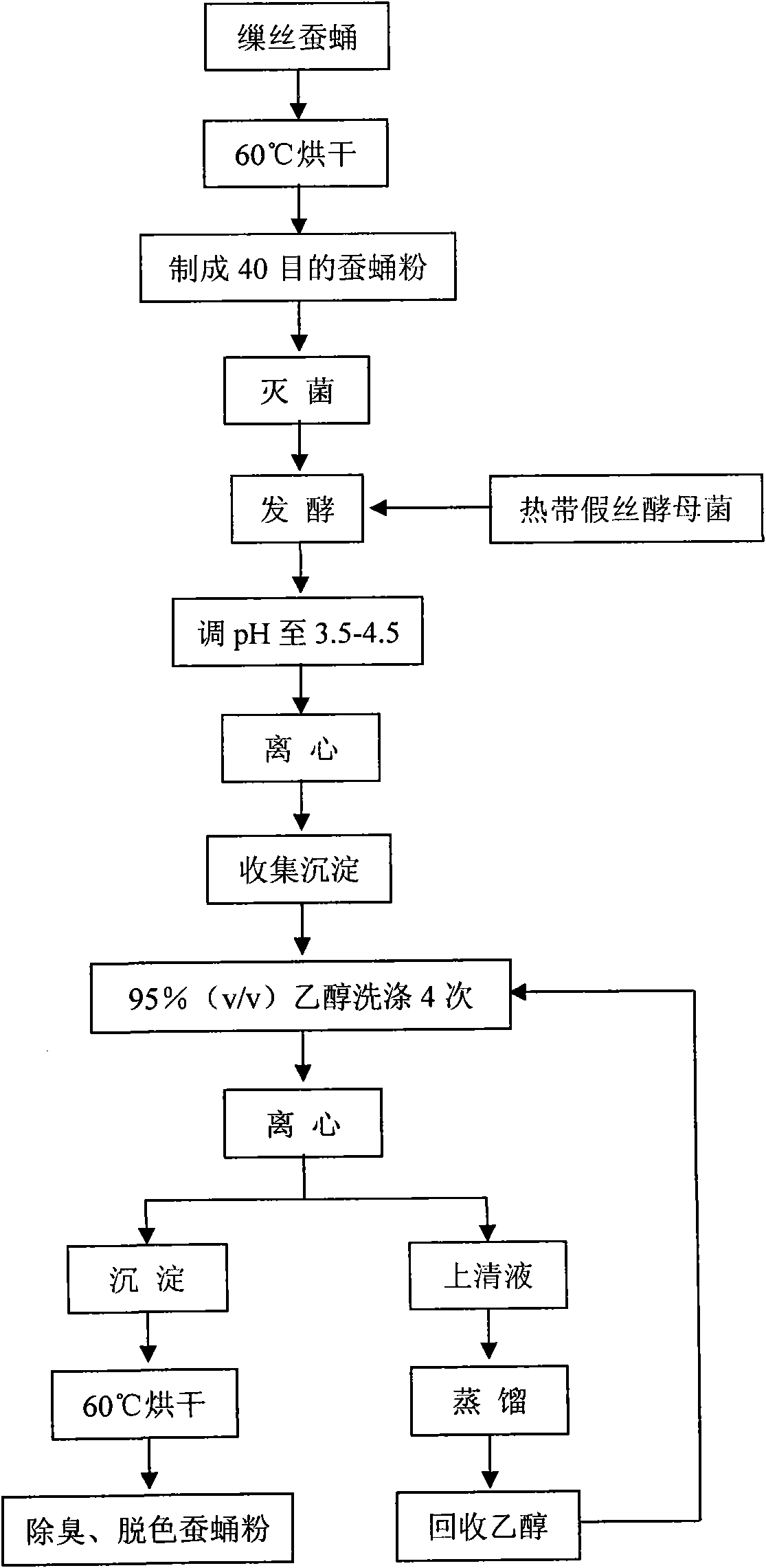

[0025] 1. Collect the silkworm chrysalis after silk reeling, dry them naturally or with hot air, and crush them through a 40-mesh sieve with an ordinary pulverizer.

[0026] 2. Microbial fermentation: take silkworm chrysalis powder and glucose with a weight ratio of 20:1, add 20 times the volume of water, sterilize at 121°C for 30 minutes, cool at room temperature, inoculate Candida tropicalis, and the inoculum size is 20 % (v / w), fermented at 35°C for 38-42 hours.

[0027] 3. Washing with ethanol: adjust the pH value of the fermentation product to 3.5-4.5 with 1mol / L hydrochloric acid, and after standing for 30 minutes, centrifuge (3000rpm, 10min) to collect the precipitate; then use 2 times the volume of 95% (v / v) Soak in ethanol at 50°C for 20 minutes, centrifuge (3000rpm, 10min) to remove ethanol, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com