Formaldehyde-free wood adhesive and preparation method thereof

A technology of wood adhesive and formaldehyde, which is applied in the field of preparation of the formaldehyde-free wood adhesive, can solve problems such as health hazards, reduction of adhesive bonding strength, excessive formaldehyde content, etc., and achieve the effects of reducing dosage, low production cost, and improving water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

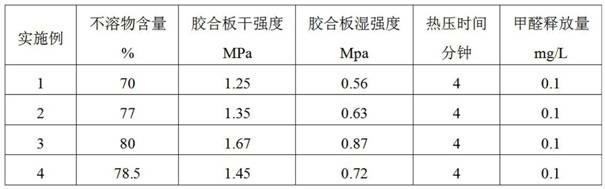

Examples

Embodiment 1

[0031] The component content and preparation method of the formaldehyde-free wood adhesive of the present embodiment are as follows:

[0032] Put 120 grams of water into a container with a stirrer, control the stirring rate to 50~200 rpm, then add 30 grams of PPE-N (0.1% urea), 35 grams of defatted soybean powder and 15 grams of defatted castor meal powder gram, 2 grams of citric acid, 1 gram of potassium sorbate, 5 grams of diatomaceous earth, the feeding interval is kept stirring continuously for 5-60 minutes according to the amount of feed, and finally homogenized with a colloid mill (it is best to add a little hydrogen when using Calcium oxide curing agent, adjust the pH to neutral), that is, a formaldehyde-free wood adhesive. Wherein the protein content in defatted soybean meal and defatted castor meal powder is 35%.

Embodiment 2

[0034] The component content and preparation method of the formaldehyde-free wood adhesive of the present embodiment are as follows:

[0035] Put 120 grams of tap water into a container with a stirrer, control the stirring rate to 50~200 rpm, then add 30 grams of PPE-N (50% urea content), 30 grams of defatted soybean powder and 20 grams of defatted cottonseed meal powder in sequence gram, 2 grams of citric acid, 2 grams of potassium sorbate, and 2 grams of glycerin. The feeding interval is kept stirring continuously for 5-60 minutes according to the amount of feeding, and finally treated with a colloid mill and a high-pressure homogenizer and then spray-dried to obtain formaldehyde-free Powder for wood adhesives. The protein content in defatted soy flour and defatted cottonseed meal is 40%.

Embodiment 3

[0037] The component content and preparation method of the formaldehyde-free wood adhesive of the present embodiment are as follows:

[0038] Put 100 grams of tap water into a container with a stirrer, control the stirring rate at 50~200 rpm, then add 50 grams of PPE-N (8% urea), 40 grams of defatted soybean powder and 20 grams of defatted pea protein powder , 0.5 grams of sodium hydroxide, 1 gram of sodium bisulfite, and 1 gram of calcium chloride. The feeding interval is kept for 5-60 minutes according to the amount of feeding, and the stirring is uniform to obtain a formaldehyde-free wood adhesive. The protein content in defatted soy flour and defatted pea protein powder is 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com