Preparation method and application of cured nano-structured epoxy resin

A technology of epoxy resin curing and nanostructure, which can be used in epoxy resin coatings, chemical instruments and methods, synthetic resin layered products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Example 1 Synthesis of Polyethylene Oxide Arm (PEO-arm), Crosslinked Divinylbenzene-Styrene Core [p(DVB-St)-core] Core Crosslinked Star Polymer

[0060] Add MPEO-Br (0.30g, 0.06mmol), cuprous chloride (0.0059g, 0.06mmol), N,N,N',N',N"-pentamethyldi Ethylenetriamine (0.024mL, 0.12mmol), divinylbenzene (0.16mL, 0.90mmol), styrene (0.10mL, 0.90mmol) and anisole (1.2mL), freezing-pumping-melting repeated three times , remove oxygen, then place the flask in a 110°C oil bath under the protection of nitrogen to stir the reaction, stop the reaction after 10h, add tetrahydrofuran to dissolve, pass through a neutral alumina column, remove the catalyst in the product, and add the filtrate dropwise to n-hexane after concentration Precipitate, filter with suction, collect the filter cake and put it in a vacuum oven at 40°C to dry to constant weight. The product is recorded as PEO / p(DVB-St)CCS polymer. Elemental analysis results: C: 66.28; H: 8.78.

Embodiment 2

[0061] Example 2 Core cross-linked star polymerization of poly(ethylene oxide-b-styrene) arm (PEO-b-PS arm), cross-linked divinylbenzene-styrene core [p(DVB-St)-core] synthesis

[0062] PEO-b-PS-Br (0.50g, 0.03mmol), cuprous chloride (0.0030g, 0.03mmol), N, N, N', N', N"- Pentamethyldiethylenetriamine (0.012mL, 0.06mmol), divinylbenzene (0.08mL, 0.45mmol), styrene (0.05mL, 0.45mmol), and anisole (1.2mL), freeze-pump -Melting was repeated three times to remove residual oxygen in the system, then placed the flask in an oil bath at 110°C under nitrogen protection and stirred for 15 hours, then added tetrahydrofuran to dissolve, passed the column to remove the catalyst, concentrated the filtrate, added dropwise to n-hexane to precipitate, and suction filtered , Collect the filter cake and put it in a 40°C vacuum oven to dry to constant weight. The product is recorded as PEO-b-PS / p(DVB-St)CCS polymer. Elemental analysis results: C: 85.26; H: 8.03.

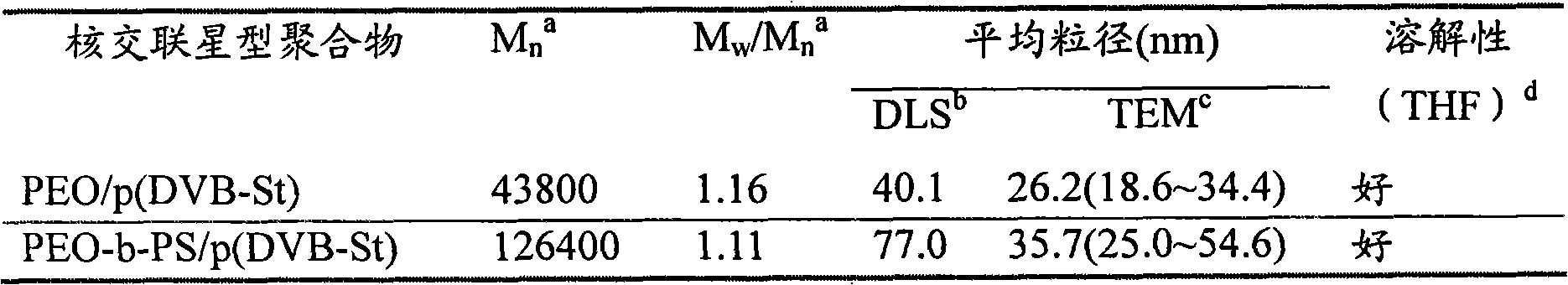

[0063] The molecular weight, a...

Embodiment 3~9

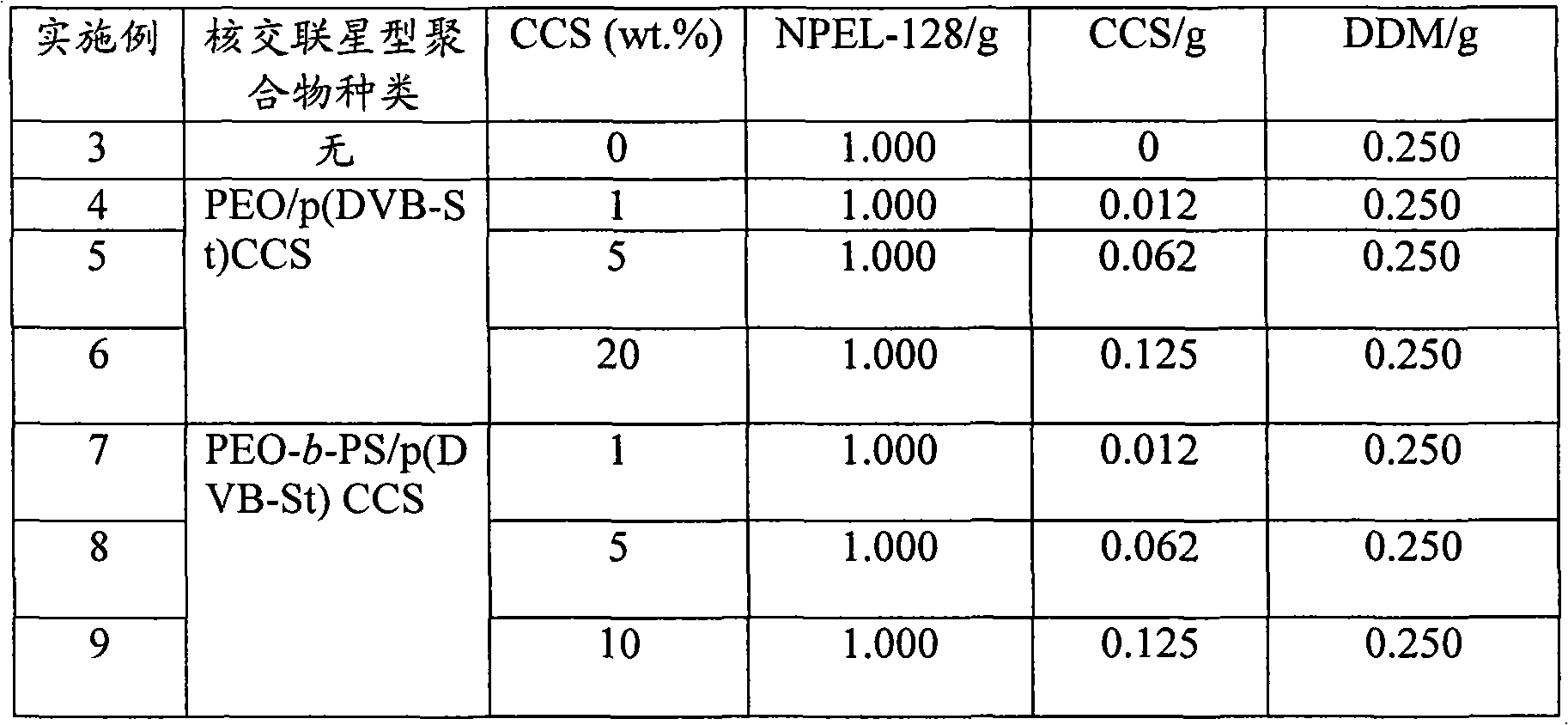

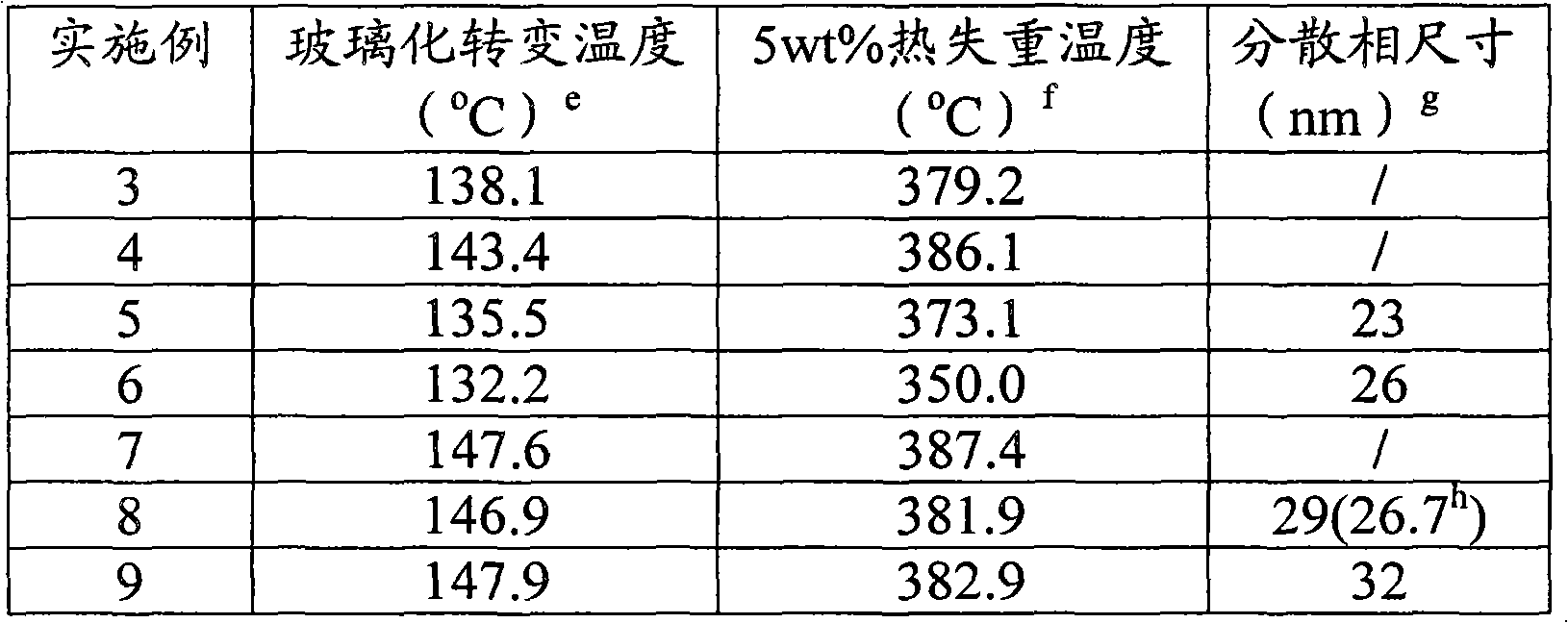

[0071] Weigh the core crosslinked star polymer (CCS), epoxy resin NPEL-128 (Shenzhen Jiadida Chemical Industry Co., Ltd.) and curing agent 4,4'-diaminodiphenylmethane (DDM) according to the weight shown in Table 1, mix Dissolve in tetrahydrofuran to obtain a homogeneous transparent solution, then remove the solvent in vacuum at 40°C, then pour it into a mold while it is hot, and put it in an oven for curing under normal pressure. Take out the cured product at room temperature. The thermal properties of the obtained cured product were characterized by DSC and TGA; the size of the dispersed phase was characterized by AFM or SEM. The selection and proportioning of each component are listed in Table 2, and the performance and structural characterization of the obtained cured product are listed in Table 3. When Examples 3-6 in Table 3 adopt PEO / p(DVB-St)CCS, the nano phase obtained is not a core-shell structure, while Examples 7-9 adopt PEO-b-PS / p(DVB-St)CCS , the nanophase of co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tg | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com