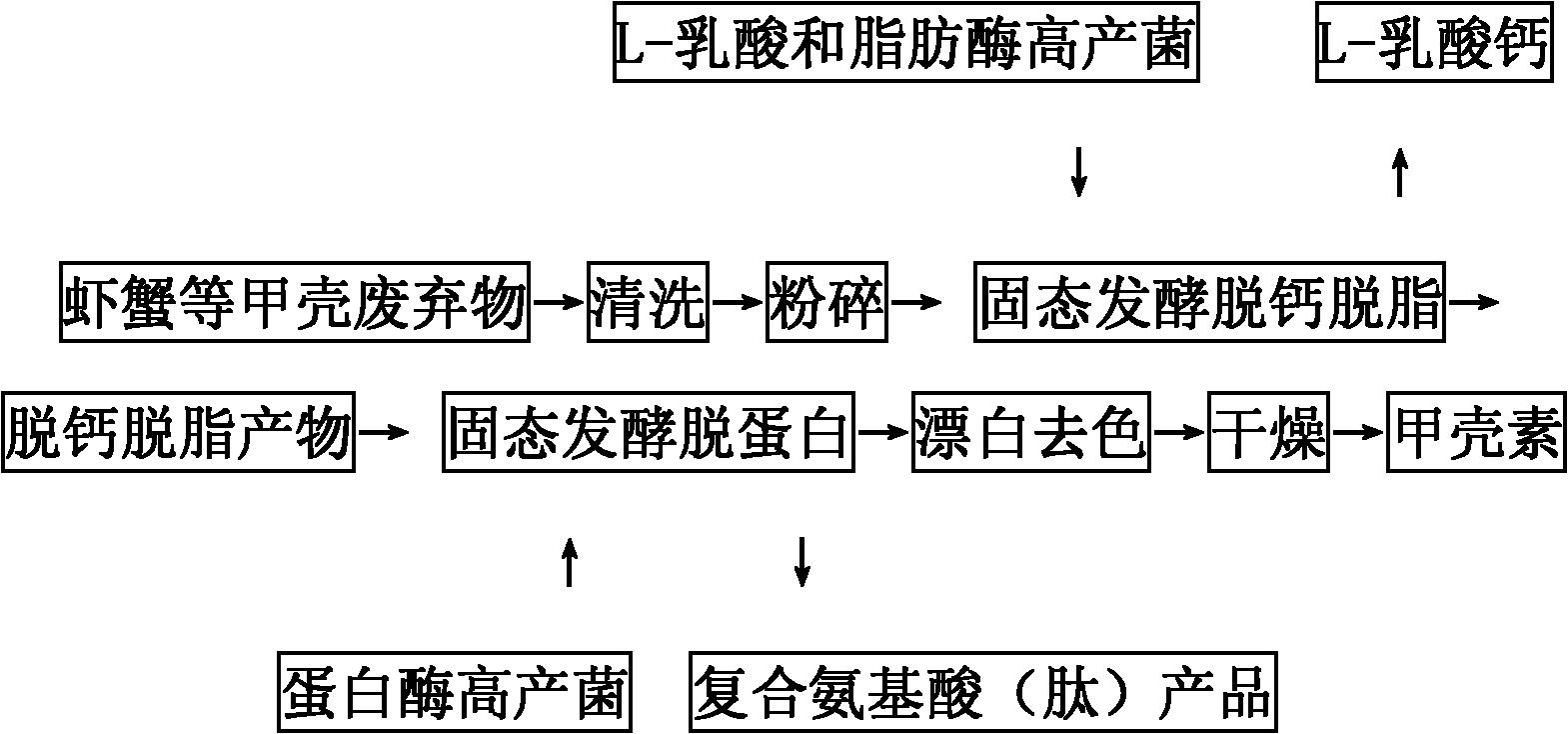

Method for preparing chitin, L-calcium lactate and compound amino acid or peptide from carapace waste

A waste, chitin technology, applied in biochemical equipment and methods, microorganism-based methods, microorganisms, etc., can solve the problems of low calcium salt removal rate, low acid production rate, high cost, and achieve high decalcification rate. , the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Preparation of chitin from crustacean waste such as shrimp and crab

[0026] 1. Clean production process and parameters

[0027] 1) Cleaning of crustacean waste such as shrimp and crab: clean the soil and other dirt on the crustacean waste such as shrimp and crab with tap water, dry and pulverize;

[0028] 2) Grinding fineness: 20-60 mesh.

[0029] 2. Solid-state fermentation decalcification and degreasing of crustacean waste

[0030] 1) Cultivation of Lactobacillus rhamnosus and Bacillus subtilis seeds

[0031] 1.1) Lactobacillus rhamnosus culture medium

[0032] A, composition of slant activation medium (g / 100ml): peptone 1%, beef extract 1%, yeast extract 0.5%, glucose 2%, diammonium hydrogen citrate 0.2%, potassium dihydrogen phosphate 0.2%, Tween 800.1% , magnesium sulfate 0.058%, manganese sulfate 0.025%, sodium acetate 0.2%, agar 2%, calcium carbonate 0.6%, sterilized at 115°C for 30min, pH 6.4.

[0033] B. Composition of liquid seed medium (g / 100m...

Embodiment 2

[0066] Example 2 Preparation of L-calcium lactate, compound amino acids or peptides from crustacean waste such as shrimp and crabs

[0067] 1. Clean production process and parameters

[0068] 1) Cleaning of crustacean waste such as shrimp and crab: clean the soil and other dirt on the crustacean waste such as shrimp and crab with tap water, dry and pulverize;

[0069] 2) Grinding fineness: 20-60 mesh.

[0070] 2. Solid-state fermentation decalcification and degreasing of crustacean waste

[0071] 1) Cultivation of Lactobacillus rhamnosus and Bacillus subtilis seeds

[0072] 1.1) Lactobacillus rhamnosus culture medium

[0073] A, composition of slant activation medium (g / 100ml): peptone 1%, beef extract 1%, yeast extract 0.5%, glucose 2%, diammonium hydrogen citrate 0.2%, potassium dihydrogen phosphate 0.2%, Tween 800.1% , magnesium sulfate 0.058%, manganese sulfate 0.025%, sodium acetate 0.2%, agar 2%, calcium carbonate 0.6%, sterilized at 115°C for 30min, pH 6.4.

[0074] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| skim rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com