Method for preparing photo-curable bone repairing material from epoxy group-containing siloxane-clad modified hydroxyapatite

A hydroxyapatite and siloxane technology, which is applied in the field of biocomposite medical materials, can solve problems such as inorganic particle/polymer matrix interface fracture, achieve biocompatibility, improved mechanical properties, simple preparation process, and good biological properties. Effects of Compatibility and Mechanical Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

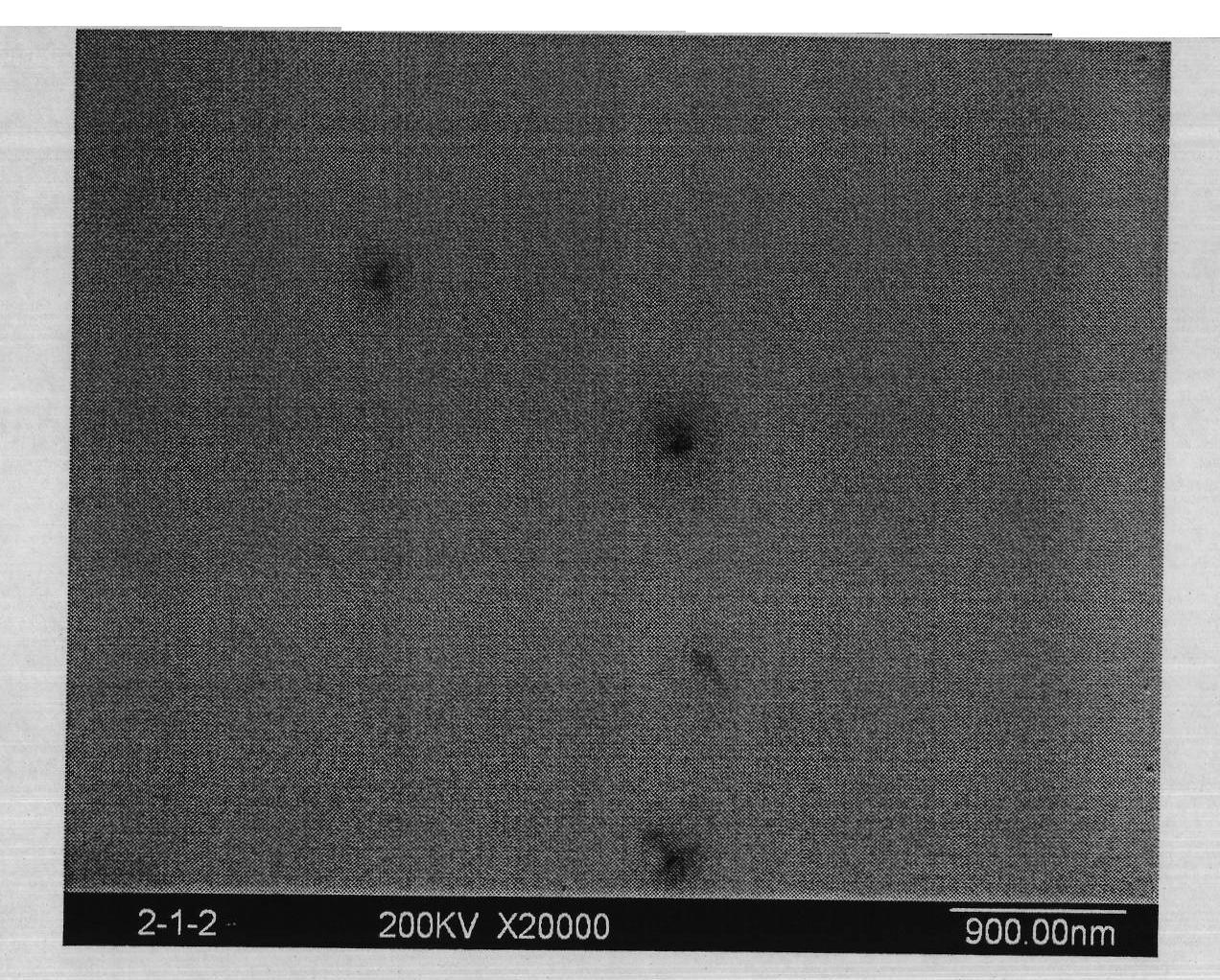

[0018] Weigh 5.0 g of nano-hydroxyapatite, suspend it in 40.0 mL of ethyl acetate, stir it electromagnetically, control the temperature at 5° C., and protect it with nitrogen. Add dropwise an ethyl acetate solution in which 10.0 g of propyltriethoxysilane isocyanate and dibutyltin dilaurate are dissolved, react for 3 hours, wash, centrifuge, and dry in vacuo. Take 0.2g of the dried sample, 1.0g of water, 3.0g of 3-glycidyloxypropyltrimethoxysilane, and the photoinitiator diazonium salt content is 1.0% of the system, add 0.1mL of hydrochloric acid and 0.2mL of ethanol, Let the solution system slowly form a white gel, at a light intensity of 10mW / cm 2 , Polymerized for 5 minutes under a UV lamp with a wavelength of 200-500nm to obtain the product.

Embodiment 2

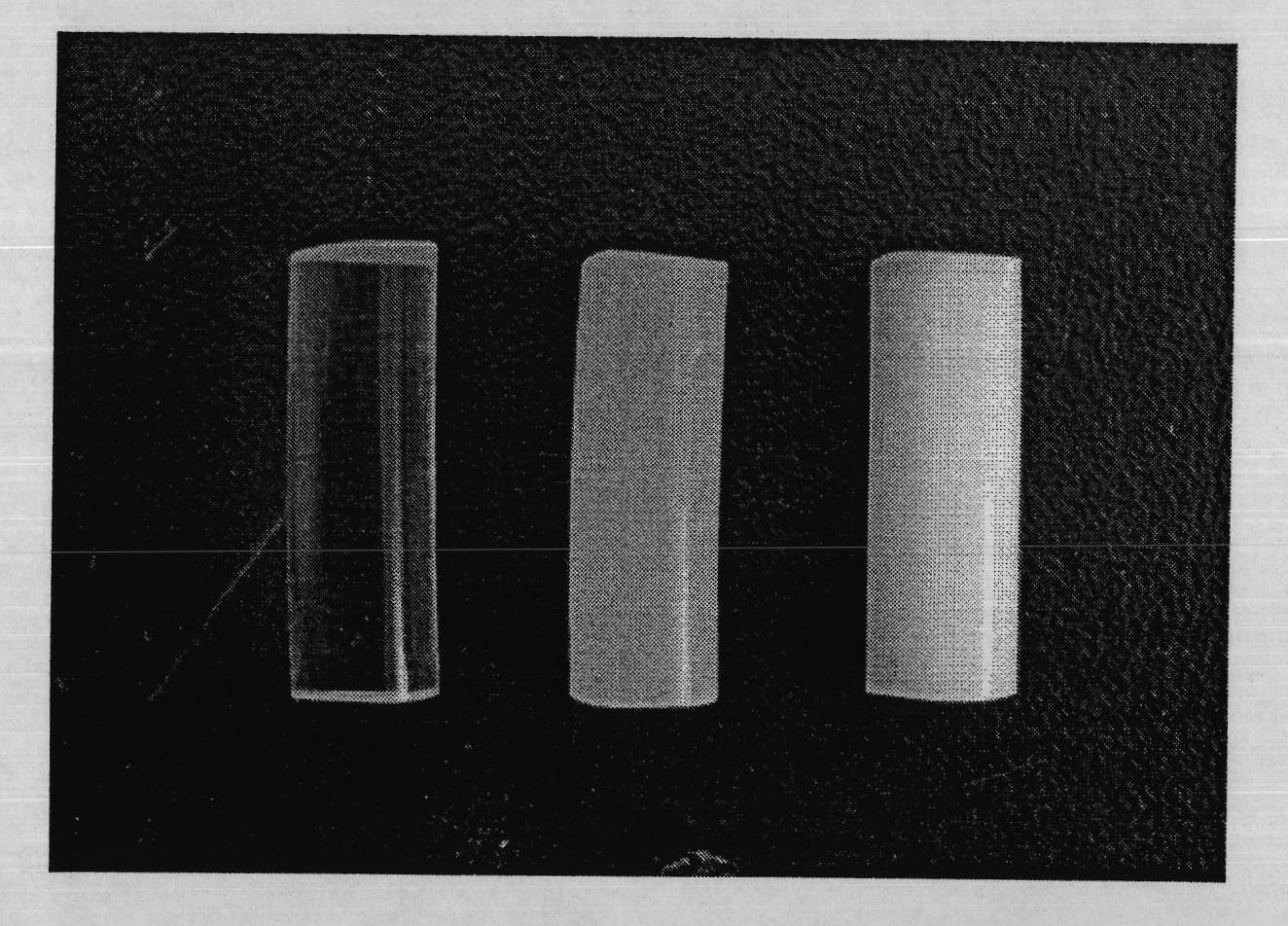

[0020] Weigh 5.0 g of nano-hydroxyapatite, suspend it in 40.0 mL of tetrahydrofuran, stir it electromagnetically, control the temperature at 20° C., and protect it with nitrogen. A tetrahydrofuran solution dissolved with 10.0 g of propyltrimethoxysilane isocyanate and triethylenediamine as a catalyst was added dropwise, and after reacting for 3 hours, it was washed, centrifuged, and dried in vacuum. Take 0.8g of dried sample, 1.0g of water, 3.0g of 3-glycidyl etheroxypropylmethyl diethoxysilane, and the content of photoinitiator diaryliodonium salt / 651 is 1.0% of the system, add 0.1mL ammonia water and 1.0mL methanol, let the solution system slowly form a white gel, under the light intensity of 50mW / cm 2 , Polymerized for 10 minutes under a UV lamp with a wavelength of 200-500nm to obtain the product. After mechanical property testing, the compressive strength of the sample is 650MPa.

Embodiment 3

[0022] Weigh 5.0 g of nano-hydroxyapatite, suspend it in 40.0 mL of N,N-dimethylformamide, stir it electromagnetically, control the temperature at 100° C., and protect it with argon. Add 10.0g of 3-glycidyl etheroxypropyltriethoxysilane and catalyst dimethylimidazole nitrogen, nitrogen-dimethylformamide solution dropwise, and react for 3 hours, wash, centrifuge, and vacuum dry . Take 1.6g of the dried sample, 1.0g of water, 3.0g of 3-glycidyloxypropyltriethoxysilane, the content of the photoinitiator triarylsulfonium salt is 1.0% of the system, add 0.1mL of sodium hydroxide and propanol 1.0mL, let the solution system slowly form a white gel, under the light intensity of 200mW / cm 2 , The product was obtained by polymerizing for 20 minutes under a UV lamp with a wavelength of 200-500nm. After mechanical property testing, the compressive strength of the sample was 650MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com