Potassium-bismuth titanate-based solid solution lead-free piezoelectric ceramic and manufacturing method thereof

A potassium bismuth titanate-based, lead-free piezoelectric technology is applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc. And bismuth-based perovskite solid solution lead-free piezoelectric ceramic electrical properties and preparation process and other issues, to achieve good piezoelectric and electromechanical coupling properties, good piezoelectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The specific steps of the preparation method are:

[0054] 1. From MgO, ZnO, CoO, NiO, TiO 2 , ZrO 2 , Nb 2 o 5 , WO 3 Select the raw material in, according to the chemical formula C 2x D. 2y o 3 Ingredients;

[0055] 2. The prepared raw materials are mixed by ball milling for 6-12 hours with absolute ethanol as the medium, and after drying, they are calcined in an alumina crucible at a temperature of 1200-1450°C for 1-4 hours;

[0056] 3. Synthesized C 2x D. 2y o 3 and K again 2 CO 3 , Bi 2 o 3 ,TiO 2 , Fe 2 o 3 , Sc 2 o 3 , Y 2 o 3 , In 2 o 3 Raw materials such as, carry out batching according to general formula (1);

[0057] 4. The prepared raw materials are mixed by ball milling for 6-12 hours with absolute ethanol as the medium, and after drying, they are calcined in an alumina crucible at a temperature of 850-1000°C for 1-4 hours;

[0058] 5. After the pre-synthesized powder is ground, it is still finely ground for 22-23 hours with absolut...

Embodiment 1

[0065] Carry out each step successively according to above-mentioned embodiment mode, wherein,

[0066] Using (1-n){(1-u)(Bi 0.5 K 0.5 )TiO 3 +u[(1-z)Bi((Mg 0.5 Ti 0.5 )O 3 +zBiScO 3 ]}+nCuO composed of piezoelectric ceramics, the first step of calcination temperature is 1400 ℃, time is 4 hours, the second step calcination temperature is 900 ℃, time is 3 hours. After two calcinations, ball mill again for 24 hours with absolute ethanol as the ball milling medium. The formed green body was then sintered at 1100° C. for 2 hours.

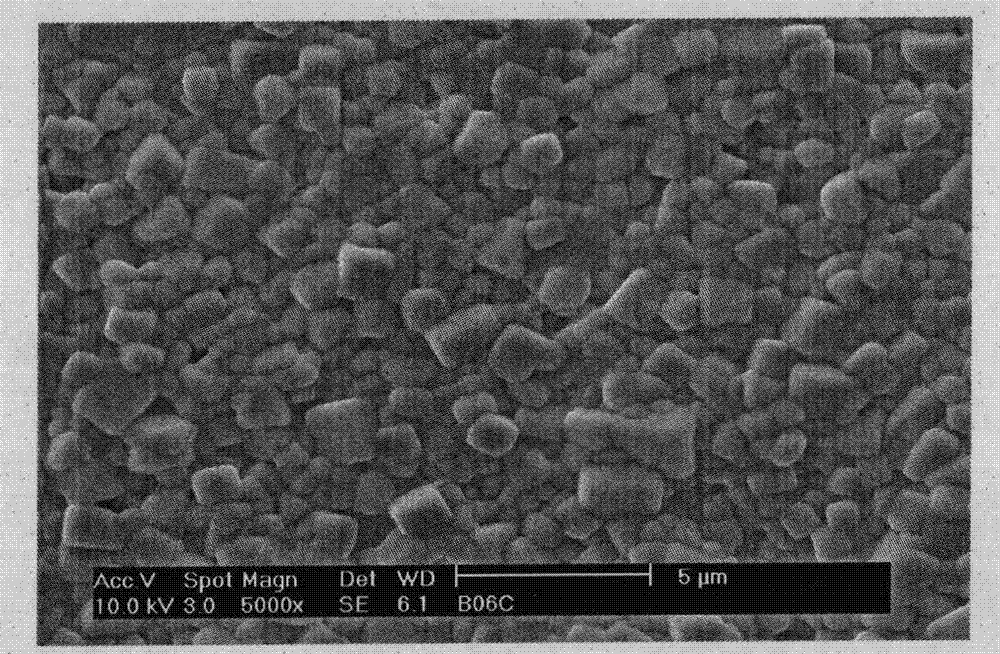

[0067] When u = 0.12, z = 0.05 and n = 0.005, the scanning electron micrograph of the sample after sintering at 1100 ° C for 2 hours is as follows figure 1 shown.

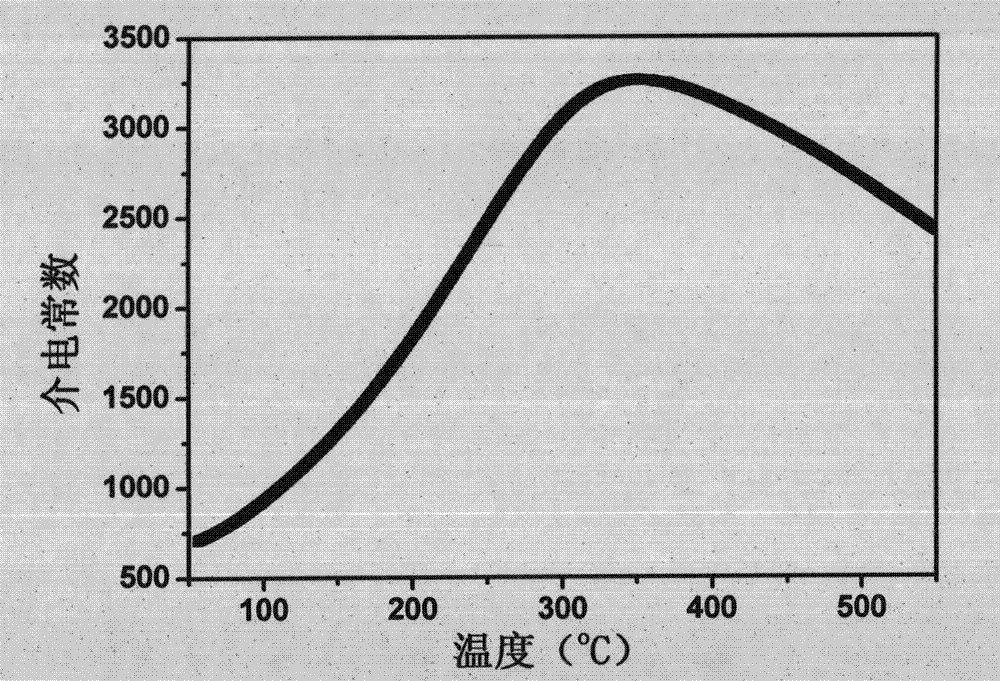

[0068]When u=0.12, z=0.05 and n=0.005, the sample was sintered at 1100°C for 2 hours, and the dielectric-temperature curve at 1MHz is as follows figure 2 shown.

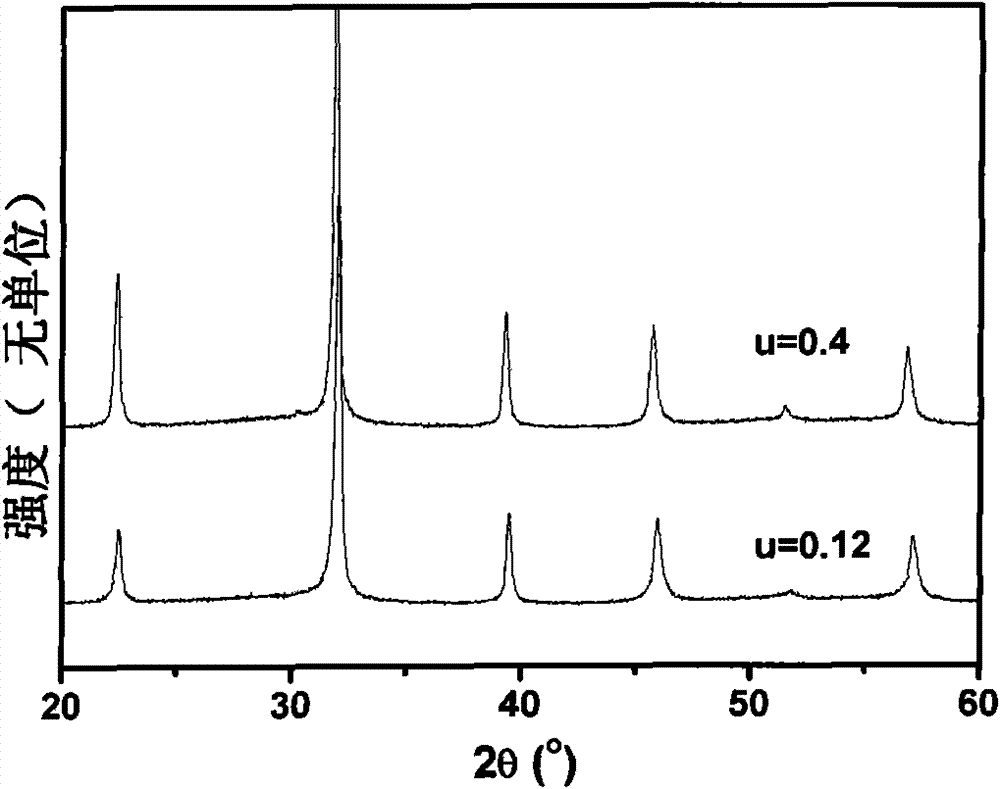

[0069] When z=0.05 and n=0.005, and u are 0.12 and 0.4 respectively, the X-ray diffraction pattern of the sample is a...

Embodiment 2

[0074] Carry out each step successively according to above-mentioned embodiment mode, wherein

[0075] Using (1-n){(1-u)(Bi 0.5 K 0.5 )TiO 3 +u[(1-z)Bi((Ni 2 / 3 Nb 1 / 3 )O 3 +zBiFeO 3 ]}+nAgO is composed of piezoelectric ceramics, when u=0.1, z=0.03, and n is 0 and 0.005 respectively, the first step of calcination temperature is 1350 ℃, time is 4 hours, the second The step calcination temperature is 920° C. and the time is 3 hours. After two calcinations, ball mill again for 24 hours with absolute ethanol as the ball milling medium. The X-ray diffraction pattern of the formed green body after sintering at 1050°C for 2 hours is shown in Fig. Figure 4 shown.

[0076] When u=0.1, z=0.03, and n=0, the sample was sintered at 1050°C for 2 hours, and other relevant physical property data are listed in Table 2:

[0077] Table 2

[0078]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com