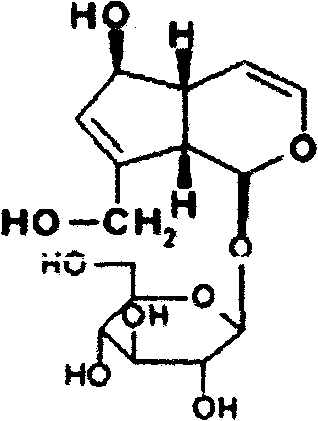

Method for extracting aucubin from aucuba japonica leaves

A technology for aucubin and aucubin, which is applied in the field of extracting aucubin by using macroporous resin and membrane separation technology, can solve the problems of large amount of organic reagents, high cost, only suitable for scientific research experiments, etc. Less, less harm, better effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Pulverize the leaves of Peach Coralia to 20 meshes, put 5kg into a microwave extraction tank, add 25L of 95% ethanol solution for microwave extraction for 1 hour, the power of microwave extraction is 1kW, the extraction temperature is controlled at 40-50°C, extract 3 times, and combine the extracts to reduce Recover the ethanol by pressure until the extract is dissolved, add water to dissolve, filter out the insoluble matter, add the filtrate to a 5L AB-8 macroporous resin column for adsorption, wash with water until the sugar reaction is negative, then elute the active ingredient with 20L of 70% ethanol solution, and collect the eluate , the eluate is added to the hollow composite membrane ultrafiltration membrane with a molecular weight cut off of 3000 for ultrafiltration, and the permeate is added to a hollow composite nanofiltration membrane with a molecular weight cut off of 100 to concentrate. The inlet pressure is controlled at 0.4-0.6Mpa to obtain a concentrated s...

Embodiment 2

[0027] Pulverize the leaves of Peach Coralia to 80 mesh, take 5kg and put it into a microwave extraction tank, add 75L80% ethanol solution for microwave extraction for 2 hours, the power of microwave extraction is 3kW, the extraction temperature is controlled at 40-50°C, extract 2 times, combine the extracts to reduce Press to recover the ethanol until the extract is dissolved, add water to dissolve, filter out the insoluble matter, add the filtrate to a 5L NAK-II macroporous resin column for adsorption, wash with water until the sugar reaction is negative, then use 35L of 50% ethanol solution to elute the active ingredients, and collect the eluate , the eluate is added to the hollow composite membrane ultrafiltration membrane with a molecular weight cut-off of 6000 for ultrafiltration, and the permeate is added to a hollow composite nanofiltration membrane with a molecular weight cut-off of 100 to concentrate, and the inlet pressure is controlled to 0.5-0.7Mpa to obtain a conce...

Embodiment 3

[0029] Pulverize the leaves of Peach Coralia to 60 mesh, put 5kg into a microwave extraction tank, add 50L90% ethanol solution for microwave extraction for 1 hour, the power of microwave extraction is 4kW, the extraction temperature is controlled at 40-50°C, extract 3 times, combine the extracts to reduce Recover the ethanol by pressure until the extract is dissolved, add water to dissolve, filter out the insoluble matter, add the filtrate to a 5L ADS-7 macroporous resin column for adsorption, wash with water until the sugar reaction is negative, then elute the active ingredient with 30L of 60% ethanol solution, and collect the eluate , the eluate is added to ultrafiltration with a hollow composite membrane with a molecular weight cut off of 6000, and the permeate is added to a hollow composite nanofiltration membrane with a molecular weight cut off of 100 to concentrate, and the inlet pressure is controlled at 0.6-0.8Mpa to obtain a concentrated solution, and 5 times the amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com