Medical hydrogel dressings and preparation method thereof

A hydrogel, medical technology, applied in the field of dressings and its preparation, can solve the inconvenience of observing wound healing and other problems, achieve excellent resistance to bacterial invasion, reduce production costs, non-irritating and sensitizing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

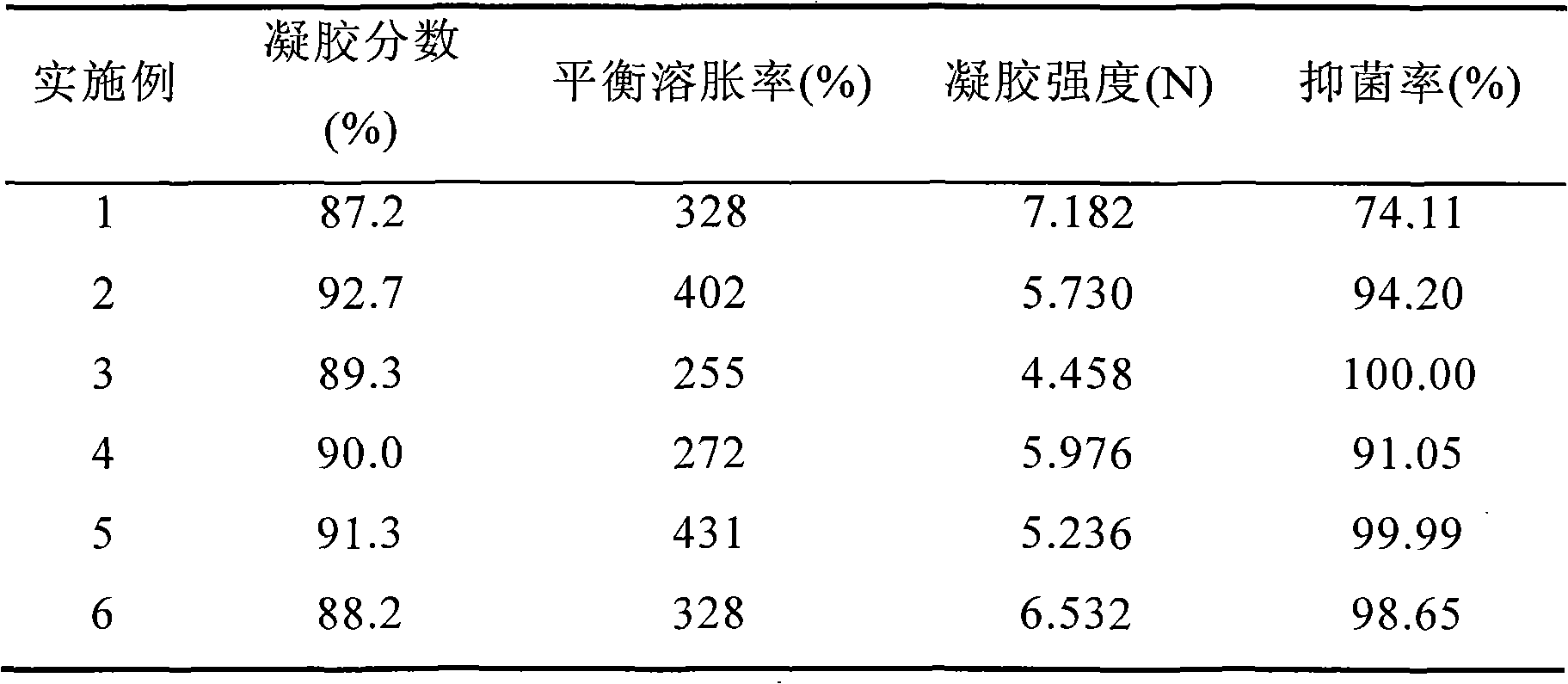

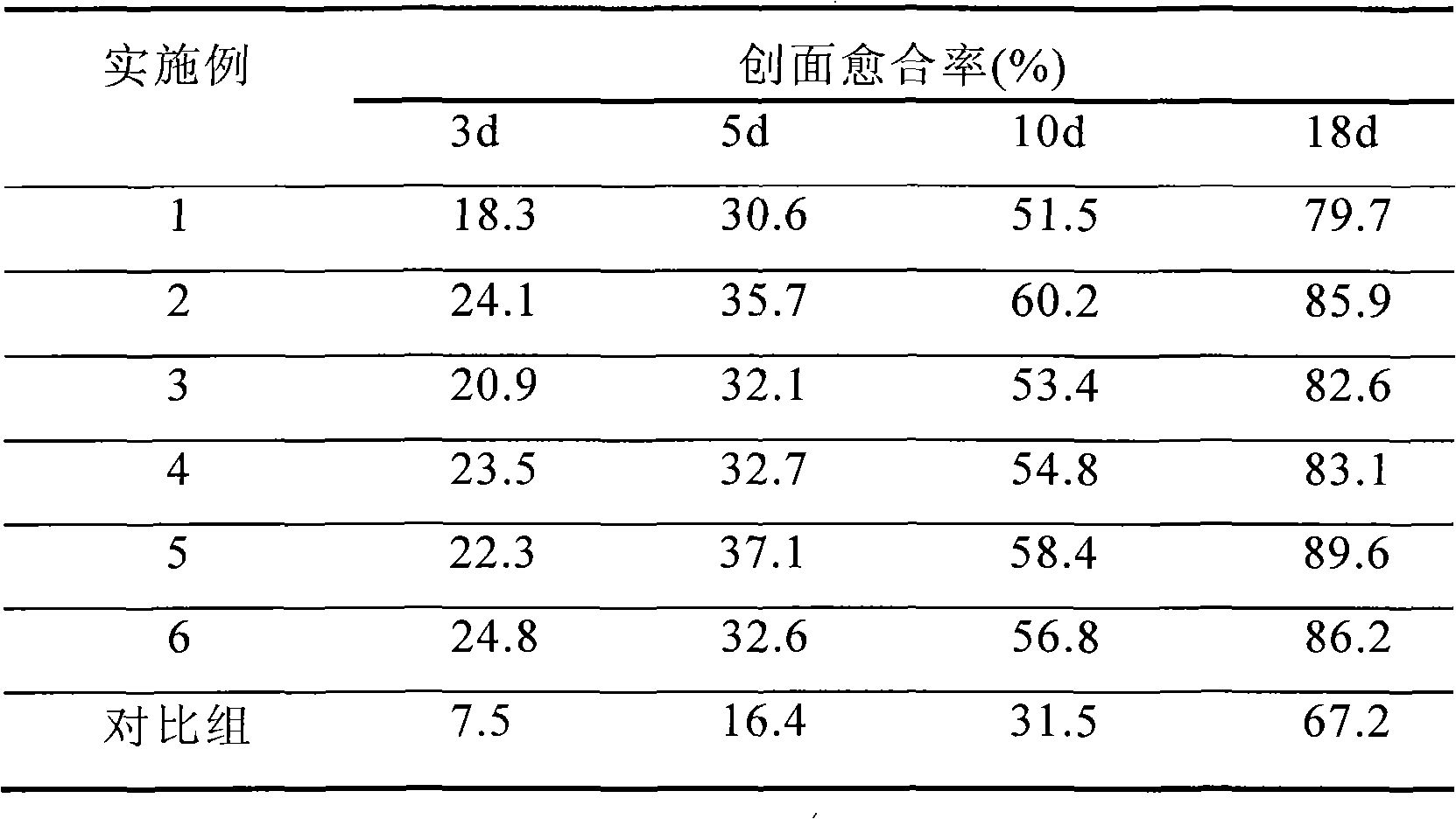

Examples

Embodiment 1

[0058] Disperse 10g of polyvinyl alcohol powder and 5g of agar in 70g of deionized water, heat up to 85°C to dissolve, cool down to 40°C, wherein the degree of polymerization of polyvinyl alcohol is 2400, and the degree of alcoholysis is 99%; disperse 10g of wheat starch in Add 10g of deionized water to the above polyvinyl alcohol and agar solution, stir evenly, adjust the pH value of the system to 9 with 3wt% NaOH solution, then raise the temperature to 95°C and keep it for 20min, then cool down to 30°C; add 0.8g polytetramethylene Guanidine hydrochloride was formulated into an aqueous solution with a mass concentration of 2%, added to the reaction system, and stirred evenly; then 5g of epichlorohydrin was added, stirred to form a mixed solution, the mixed solution was poured into a mold, and placed at 60°C for 3 hours to react to obtain Antibacterial hydrogel dressing.

Embodiment 2

[0060] Disperse 10g of polyvinylpyrrolidone powder in 50g of deionized water, stir to dissolve, wherein the molecular weight of polyvinylpyrrolidone is 1000000; disperse 15g of potato starch in 30g of deionized water, add it to the above polyvinylpyrrolidone solution, stir well, and use 2wt Adjust the pH value of the system to 10 with % NaOH solution, then raise the temperature to 80°C and keep it for 30 minutes, then cool down to 40°C; prepare 1.6g of polyhexamethylene guanidine hydrochloride into an aqueous solution with a mass concentration of 5%, add it to the reaction system, and stir evenly Add 4g of ethylene glycol diglycidyl ether, stir to form a mixed solution, pour the mixed solution into a mold, and place it at 75°C for 3 hours to obtain an antibacterial hydrogel dressing.

Embodiment 3

[0062] Disperse 5g of polyvinyl alcohol powder and 2g of gelatin in 20g of deionized water, heat up to 85°C to dissolve, cool down to 40°C, wherein the degree of polymerization of polyvinyl alcohol is 8000, and the degree of alcoholysis is 91.5%; disperse 18g of soluble starch in Add 60g of deionized water to the above polyvinyl alcohol and gelatin solution, stir evenly, adjust the pH value of the system to 11 with 4wt% NaOH solution, then raise the temperature to 85°C and keep it for 15min, then cool down to 30°C; 3.0g of polyoctamethylene Guanidine hydrochloride is formulated into an aqueous solution with a mass concentration of 10% and added to the reaction system, and stirred evenly; then 6g of glycerol triglycidyl ether is added, stirred to form a mixed solution, the mixed solution is poured into a mold, and placed at 70°C for reaction 4h, get antibacterial hydrogel dressing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com