Polymer surfactant and core-shell amphiphilic polymer microsphere as well as preparation method thereof

A technology of surfactants and macromolecules, applied in the direction of grafted polymer adhesives, adhesive types, adhesives, etc., can solve the problems of difficult control of the structure, high requirements for experimental conditions, cumbersome process routes, etc., and achieve simple routes , the effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: the preparation of macromolecule surfactant (1):

[0042]

[0043] (1) Add sodium hydroxide (8g, 0.20mol), 40ml deionized water, tetra-tert-butylammonium bromide (3.2g, 0.01mol), THF (40ml) and dodecanethiol ( 40.48g, 0.20mol), stirred mechanically, cooled to room temperature, added CS 2 (15.23g, 0.20mol), after cooling to room temperature, α-bromopropionic acid (30.6g, 0.20mol) was added. Cool to room temperature (20° C.) with a water bath, remove the water bath, and stir at room temperature for 20 h. The oil bath was heated to 50°C for 3h. Stop heating, adjust the acidity with dilute hydrochloric acid solution, make the pH of the system 1, extract with an appropriate amount of ether, separate the liquid, separate the upper yellow organic layer, dry the organic layer with anhydrous sodium sulfate, and remove it by rotary evaporation with a rotary evaporator Tetrahydrofuran was used as a solvent to obtain an orange viscous liquid, which was left at r...

Embodiment 2

[0046] Embodiment 2: the preparation of a kind of macromolecule surfactant (2).

[0047] (1) The operation steps are the same as step (1) of Example 1 to obtain a bright yellow solid (A).

[0048] (2) In a four-neck flask equipped with a stirrer, a condenser, a thermometer and a vent pipe, add 3.51 g of the obtained bright yellow solid (A) (0.01 mol) and 40 g of toluene, stir and dissolve to obtain a transparent solution 1.

[0049] (3) Add 14.4 g (0.2 mol) of acrylamide and 1.68 g (10 mmol) of azobisisoheptanonitrile into solution 1, stir and dissolve under nitrogen protection. The temperature was raised to 50°C, and the reaction was stirred for 8 hours. Then, most of the organic solvent was removed under reduced pressure to obtain a light yellow macromolecular surfactant as a solid. Number average molecular weight (Mn) is 1810; weight average molecular weight (Mw) is 2240; polydispersity index: 1.24.

Embodiment 3

[0050] Embodiment 3: the preparation of macromolecule surfactant (3)

[0051]

[0052] (1) Same as step (1) of Example 1 to obtain a bright yellow solid (A).

[0053] (2) In a four-necked flask equipped with a mechanical stirrer, a condenser tube, a thermometer and a ventilation tube, add 3.51 g of the yellow solid (A) (0.01 mole) obtained in step (1) and 40 g of toluene, stir and dissolve, and obtain a transparent Solution 2.

[0054] (3) Add 3.6 g (0.05 mol) of acrylic acid, 0.05 mol of methacrylic acid, and 0.21 g (1.25 mmol) of azobisnitrile valeric acid into solution 1, stir and dissolve under nitrogen protection. The temperature was raised to 65°C, and the reaction was stirred for 8 hours. Then, 6.4 g (0.05 mol) of isopropyl acrylate and 15 g of toluene were added, and the reaction was continued at 65° C. for 8 hours. Then, most of the organic solvent was removed under reduced pressure to obtain a light yellow macromolecular surfactant as a solid. Number average m...

PUM

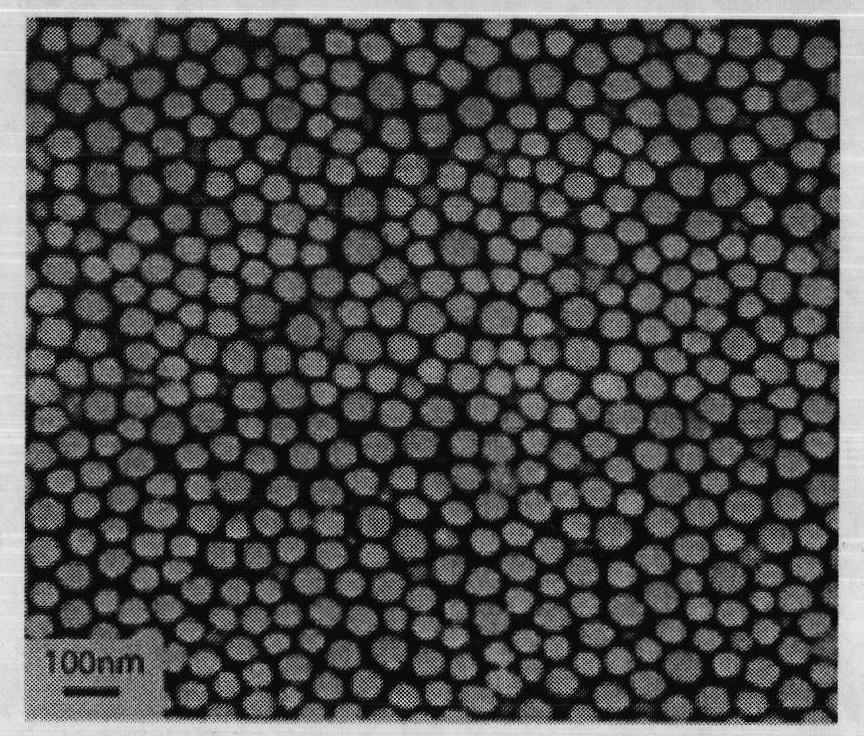

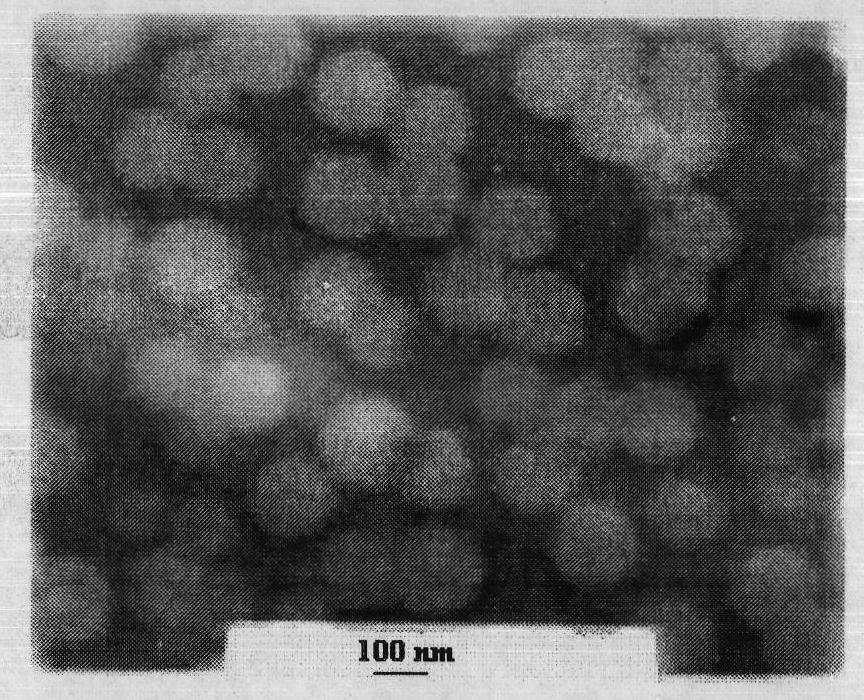

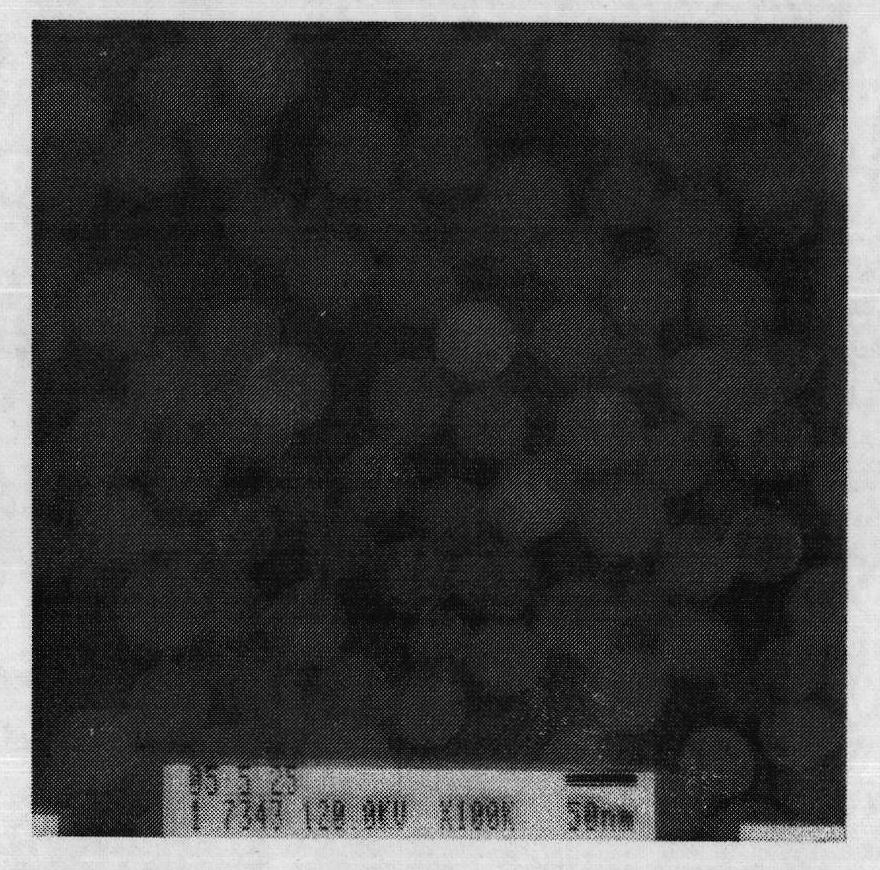

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com