Method for preparing hydrogen by fermentation through using special anaerobic clostridium pasteurianum

A technology of anaerobic bacteria and fermentation substrate, applied in the field of hydrogen production by using efficient anaerobic bacteria, can solve problems such as difficult promotion, weak screening research, anaerobic fermentation conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

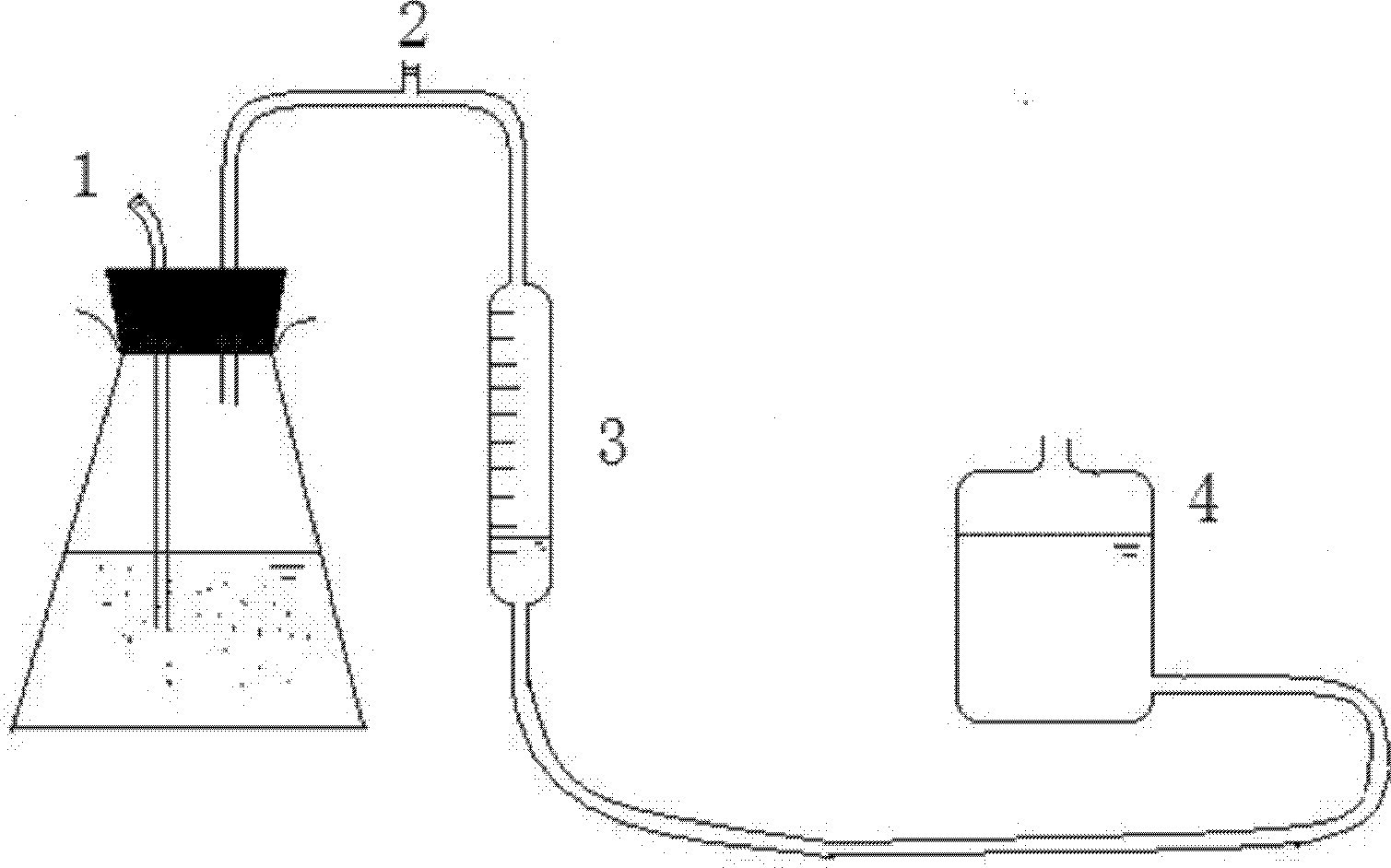

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Determine the basal medium for expanded culture of strains

[0023] The medium composition is: peptone 10g / L, beef extract 2.4g / L, yeast extract 5.0g / L, Na 2 HPO 4 4g / L, L-cysteine 0.2 g / L, L-cysteine hydrochloride monohydrate 0.5 g / L, horse serum 40-60 mL / L, distilled water 1000 mL. In addition, 1 mL / L of resazurin indicator (0.2%) was added. Adjust pH=6.5, put 250mL saline bottle (with bottle stopper, can be sealed) per 100mL culture medium, heat the liquid in the bottle in a water bath, and blow nitrogen gas from the bottle mouth at the same time, until the liquid phase becomes colorless (the bottle is anaerobic environment), close the bottle cap. High temperature sterilization at 120°C for 25min, drying in a 60°C oven, inoculation of the strain Clostridium pasteurianum into a bottle containing a medium (aseptic anaerobic operation), and static culture at 37°C for 24-48h.

[0024] During the culturing process, the absorbance value of the sample...

Embodiment 2

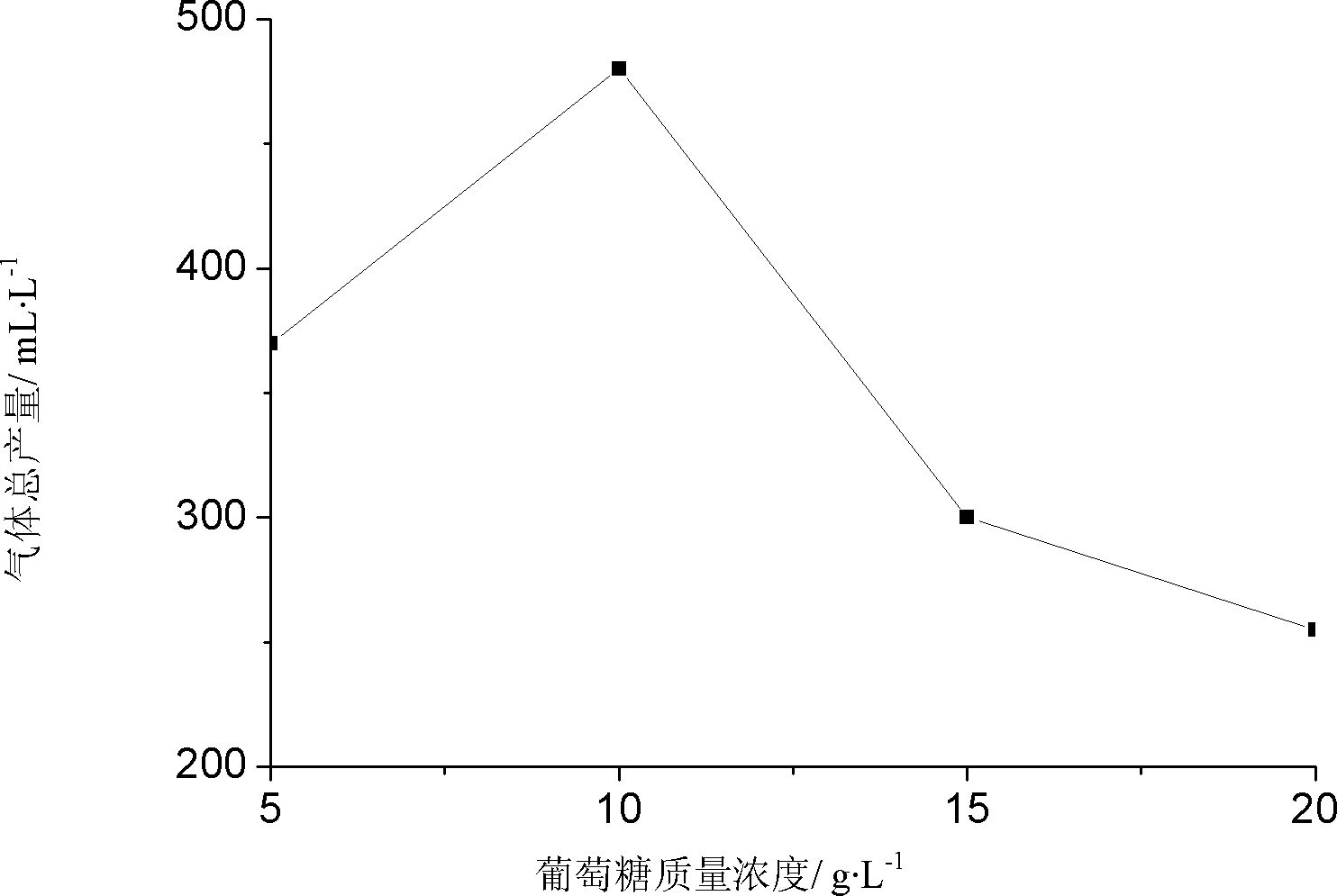

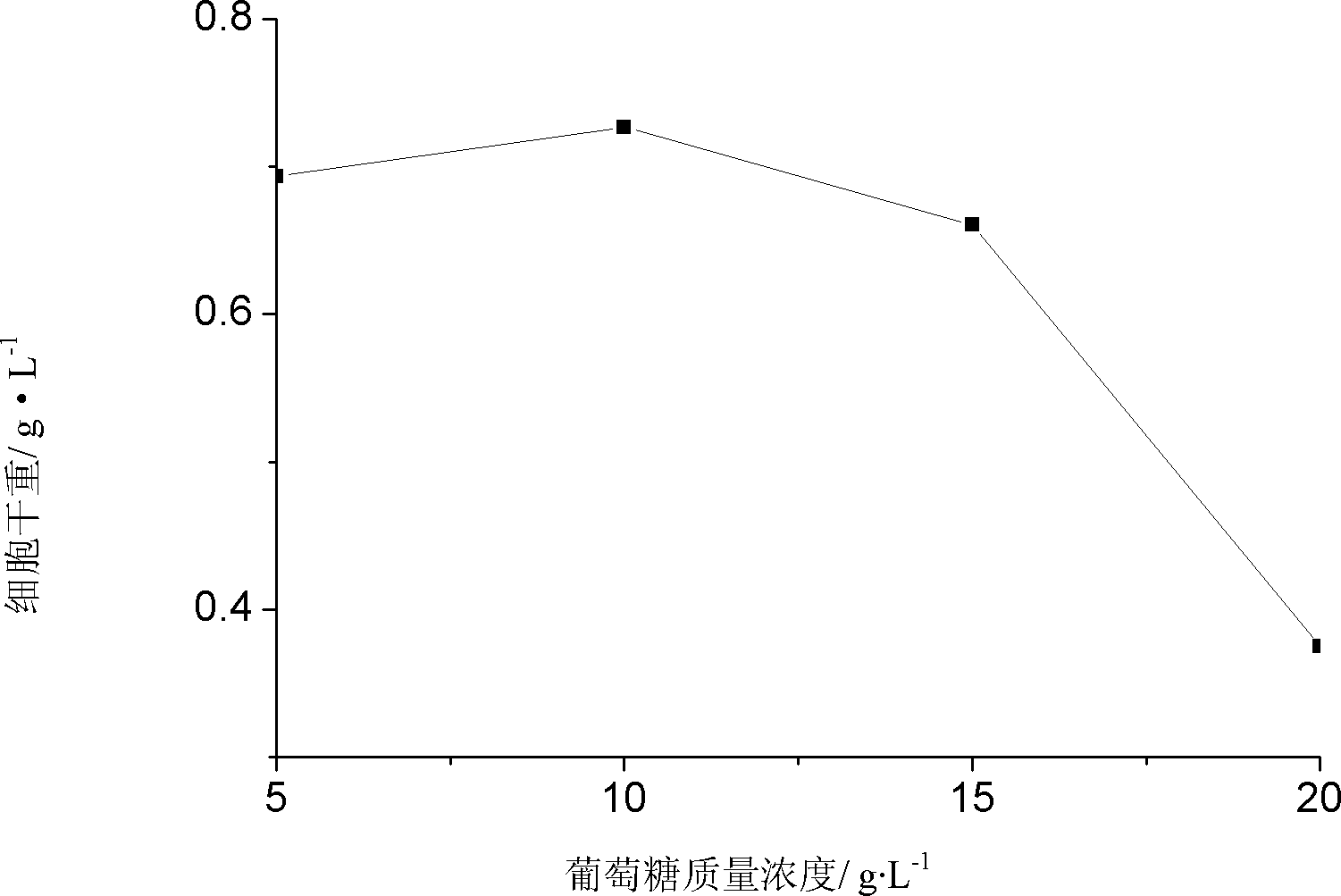

[0027] Example 2: Selection and Determination of Substrate Concentration Configuration of Bacteria Fermentation Substrate

[0028] The composition of the fermentation medium is: peptone 10g / L, beef extract 2.4g / L, yeast extract 5.0g / L, Na 2 HPO 4 4g / L, L-cysteine 0.2g / L, L-cysteine hydrochloride monohydrate 0.5g / L, horse serum 40-60 mL / L, resazurin (0.2%) 1mL / L, glucose 5~20g / L; adjust the initial pH=5.5~6.5; in the process of preparing the medium, use heating and boiling to expel the liquid phase dissolved oxygen and use nitrogen to blow off the gas phase air in the bottle to ensure strict anaerobicity at 115 ℃ high temperature sterilization for 25min; under aseptic anaerobic operation, the previously cultivated Clostridium pasteurianum OD 600 The inoculum high-concentration bacterial liquid and medium with a value of 1.402 were inoculated into the medium in the 200ml fermentation flask according to the inoculum amount in Table 1, and cultured in an anaerobic box a...

Embodiment 3

[0034] Example 3: Optimal fermentation pH determination

[0035] The effect of initial pH value on the total gas production and cell growth of C. pasteuri is shown in Tables 4 and 5. Under the condition of glucose concentration of 10 g / L, the total gas production of Clostridium pastoris fluctuated with the change of initial pH. When the initial pH is in the range of 5.0~6.0, the total gas production and cell dry weight increase with the increase of the initial pH. When the initial pH is 6.0, the total gas production reaches a maximum of 480 mL / L, and the cell dry weight reaches a maximum of 0.72 g. / L; when the initial pH continued to increase, both the total gas production and the dry cell weight decreased with the increase of the initial pH. This indicates that the initial pH of 6.0 is the optimal growth condition for Clostridium pastoris under the condition of 10g / L glucose concentration, and the value below or above this value will inhibit Clostridium pastoris.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com