Normal-temperature production method for ferrous sulfate monohydrate

A ferrous sulfate and production method technology, applied in the direction of ferric sulfate, can solve the problem of high energy consumption, and achieve the effects of low energy consumption, easy storage, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

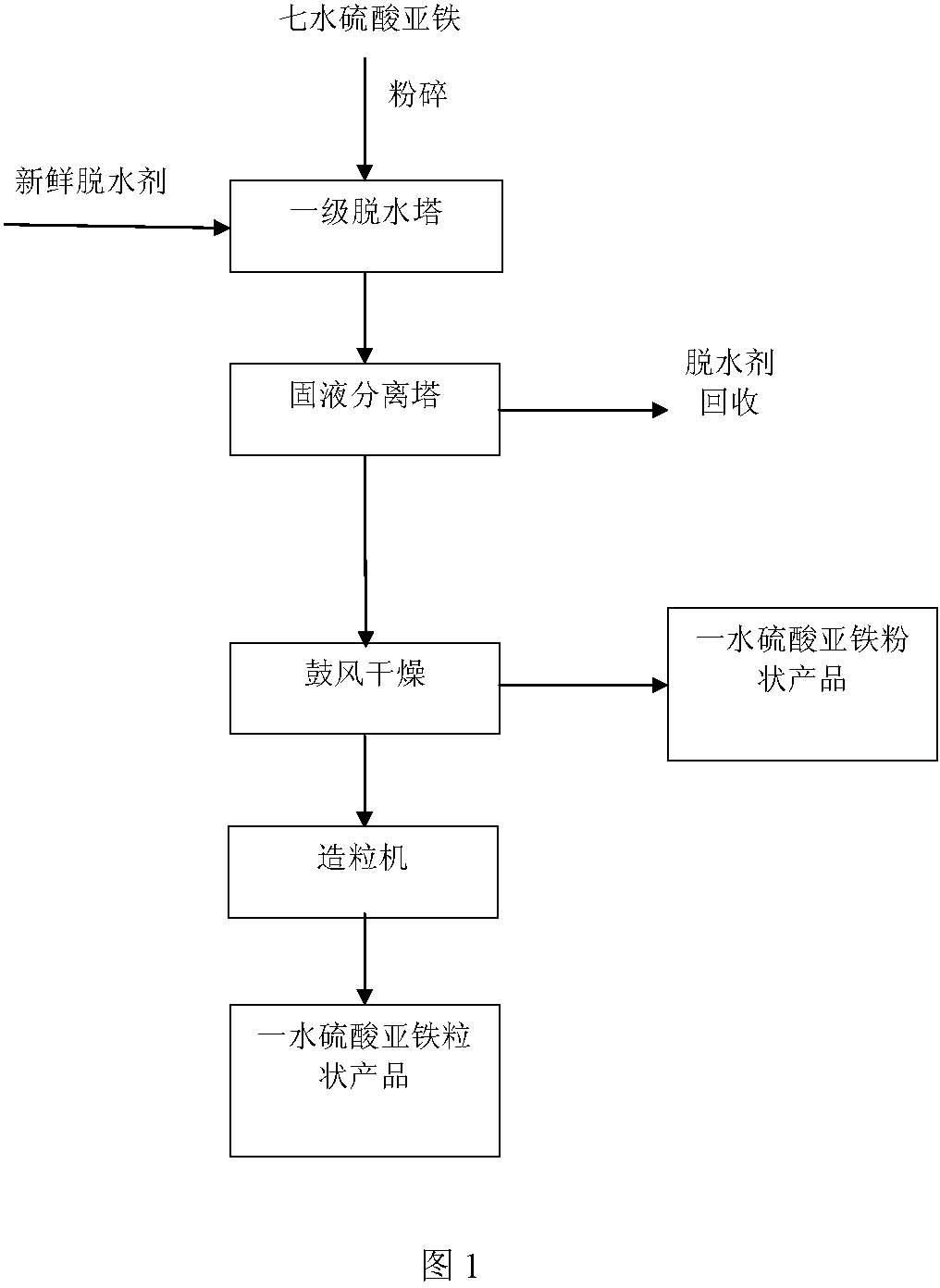

[0028] Embodiment 1, as attached figure 1 Shown, this normal temperature production method of ferrous sulfate monohydrate carries out according to the following steps: at normal temperature, ferrous sulfate heptahydrate crystal and water-soluble organic dehydrating agent (being fresh water-soluble organic dehydrating agent, referred to for short in the present invention Dehydrating agent) is mixed in a sealed container according to the mass ratio of 1:4 to 1:10, and after being fully stirred for 0.5 hours to 10 hours, the water-soluble organic solvent is dissolved to remove the crystal water in the ferrous sulfate heptahydrate crystal and dried to obtain the content It is the ferrous sulfate monohydrate powder product of 95% to 99% (i.e. purity) by weight percentage (if the production method of ferrous sulfate monohydrate at normal temperature comprises the early stage of production, the middle stage of production, and the stage of postproduction, embodiment 1 is applicable ...

Embodiment 2

[0029] Embodiment 2, as attached figure 1 Shown, this ferrous sulfate monohydrate normal temperature production method is carried out by following steps: at normal temperature, with ferrous sulfate heptahydrate crystal and water-soluble organic dehydrating agent (being fresh water-soluble organic dehydrating agent) by mass ratio 1: 4 or 1:7 or 1:10 mixed in a sealed container, after fully stirring for 0.5 hours or 6 hours or 10 hours, the water-soluble organic solvent was dissolved to remove the crystal water in the ferrous sulfate heptahydrate crystal and dried to obtain a content of The ferrous sulfate monohydrate powdery product of 95% to 99% (i.e. purity) by weight (if the normal temperature production method of ferrous sulfate monohydrate comprises the early stage of production, the middle stage of production, and the later stage of production, embodiment 2 is applicable to the early stage of production stage).

[0030] In above-mentioned embodiment 1 and 2, can fur...

Embodiment 3

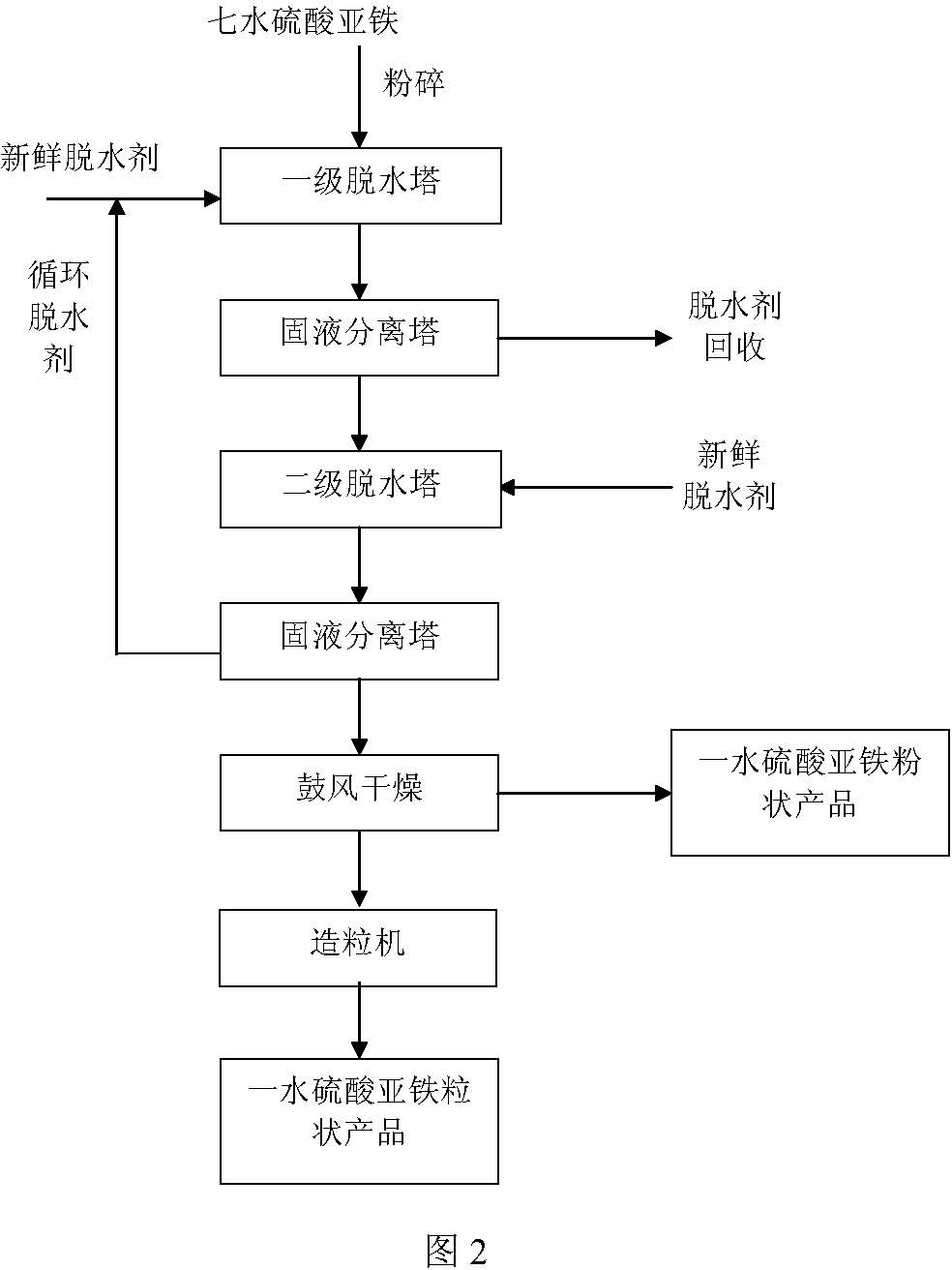

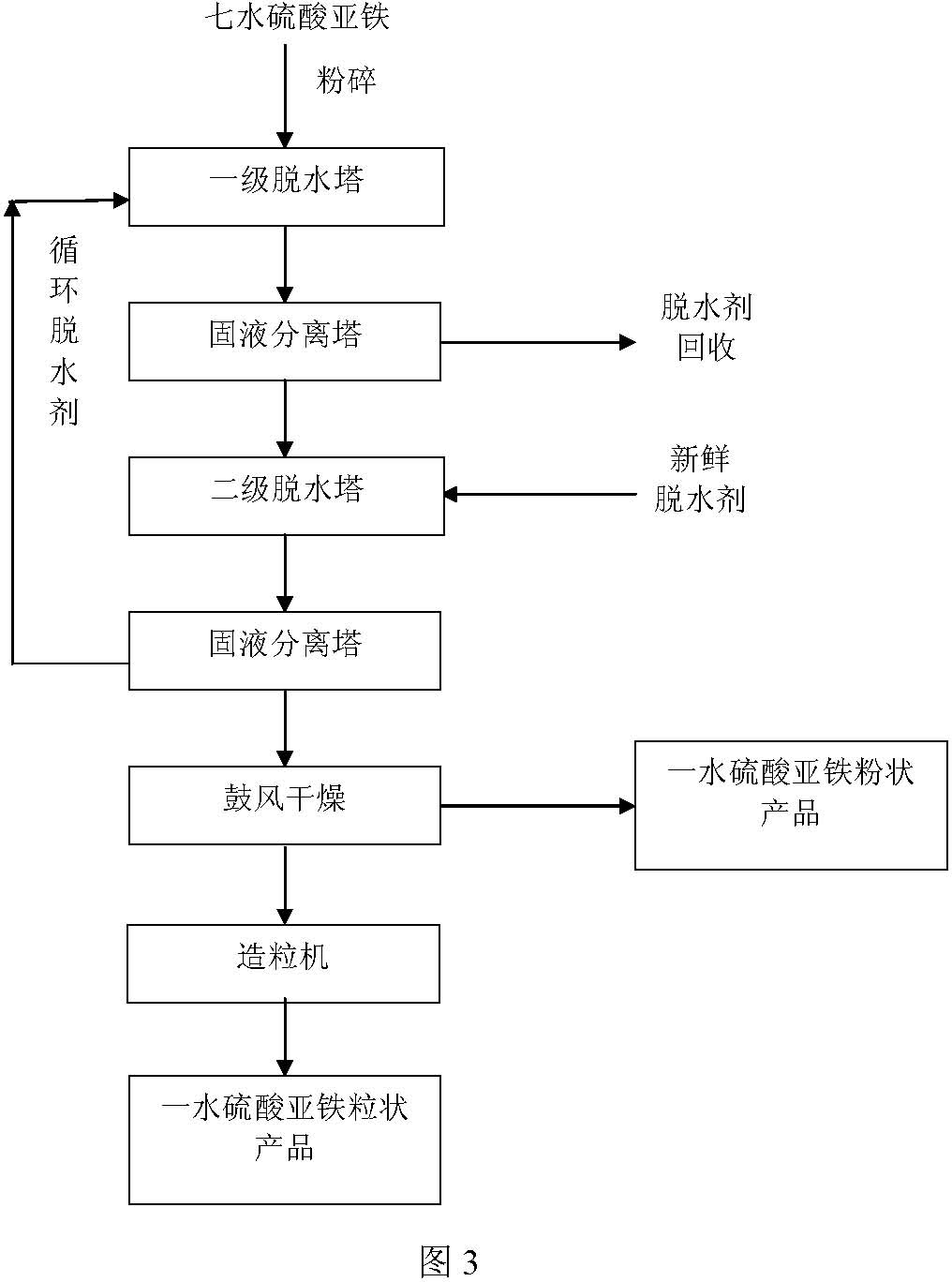

[0032] Embodiment 3, as attached figure 2 Shown, this a kind of ferrous sulfate monohydrate normal temperature production method is carried out by the following steps: at normal temperature, ferrous sulfate heptahydrate crystal and water-soluble organic dehydrating agent (being fresh water-soluble organic dehydrating agent) and containing water cycle The secondary water-soluble organic dehydrating agent is mixed in a sealed container according to the mass ratio of 1:2 to 1:10, and after being fully stirred for 0.5 hours to 10 hours, the water-soluble organic solvent is dissolved to remove part of the crystal water in the ferrous sulfate heptahydrate crystal, Obtain ferrous sulfate solid and organic aqueous solution containing part of crystal water, and the solid-liquid separation of the two obtains water-soluble organic dehydrating agent aqueous solution and solid matter respectively, and this is a first-level dehydration step; the solid matter obtained in the first-level de...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap