Preparation method of titanium alloy/biological ceramic layer composite material

A composite material and bioceramic technology, which is applied in the field of preparation of titanium alloy/bioceramic layer composite materials, can solve the problems of thin coating, limitation of the geometric structure of the substrate, and small bonding force between the coating and the substrate. The effect of good biological properties and high interfacial bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the titanium alloy / bioceramic layer composite material, the specific steps are as follows:

[0025] In the first step, the pure titanium or titanium alloy substrate is pretreated according to conventional methods. First, the outer oxide layer is polished off and drilled, and then the metal substrate is cleaned with distilled water or absolute ethanol or acetone, preferably acetone. Then fix the connecting wire of metal aluminum or copper with a length of 20cm in the hole, preferably duralumin connecting wire. Titanium alloys can be commonly used biomaterials Ti-Al-V, Ti-Zr-Nb. The substrate can be block or mesh, and when it is a mesh substrate, the mesh aperture is ≤300 μm.

[0026] The second step: preparing an aqueous electrolyte solution containing Ca, P, and Si. The reagents and concentrations used are as follows: Ca(CH 3 COO) 2 ﹒ h 2 O concentration ≤ 0.2 mol. l -1 , preferably 0.03-0.07 mol. l -1 ;NaH 2 PO 4 ﹒ 2H 2 O concen...

Embodiment 1

[0031] The pure titanium substrate is pre-polished and drilled, polished to 800# with water-grinding sandpaper, drilled to fix the connecting wire, and then the titanium substrate is cleaned with absolute ethanol to obtain a clean pure titanium substrate. Fix a 20cm long copper wire in the hole. The reagents and concentrations used to prepare the electrolyte solution are Ca(CH 3 COO) 2 ﹒ h 2 O 0.03 mol. l -1 ;NaH 2 PO 4 ﹒ 2H 2 O 0.05 mol. l -1 ; Na 2 SiO 3 ﹒ 9H 2 O 0.02 mol. l -1 ; EDTA--2Na 0.03 mol. l -1 , NaOH 0.3 mol. l -1 . The solvent is distilled water, and the solution is stirred evenly with a stirrer. Dip the clean, pure titanium substrate into the electrolyte.

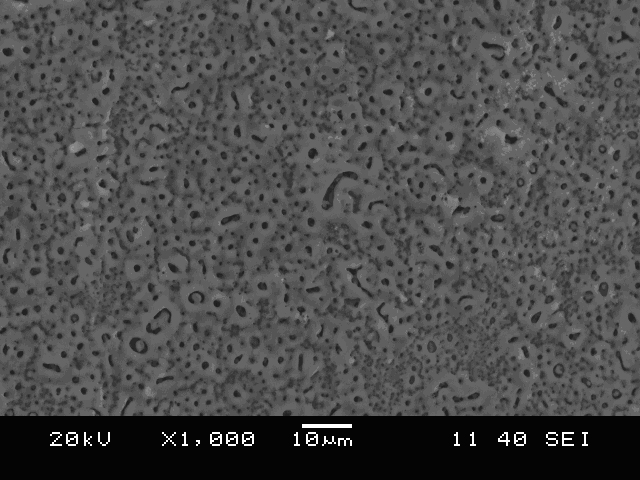

[0032] Using heteropolar pulse current power supply to prepare bio-oxidized ceramic layer, the selected parameters are: the positive current is constant at 0.5A, and the negative current is 0.5A; the positive and negative voltage will automatically increase from 0, and finally tend to a...

Embodiment 2

[0034] The pure titanium substrate is pre-polished and drilled, polished to 50# with water-grinding sandpaper, and the diameter of the drilled hole can be 4mm, and then the titanium substrate is cleaned with absolute ethanol. A 20cm long 2024 aluminum wire is fixed in the aperture. The reagents and concentrations used to prepare the electrolyte solution are Ca(CH 3 COO) 2 ﹒ h 2 O 0.07 mol. l -1 ;NaH 2 PO4﹒2H 2 O 0.06 mol. l -1 ; Na 2 SiO 3 ﹒ 9H 2 O 0.03mol. l -1 ; EDTA--2Na 0.03 mol. l -1 , NaOH 0.3 mol. l -1 . The solvent is distilled water, and the solution is stirred evenly with a stirrer.

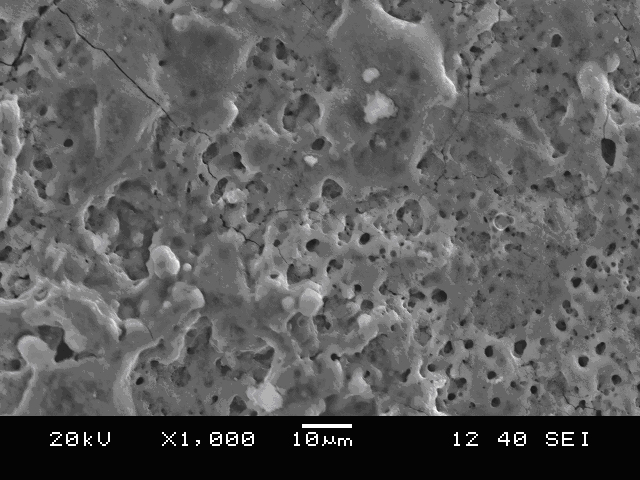

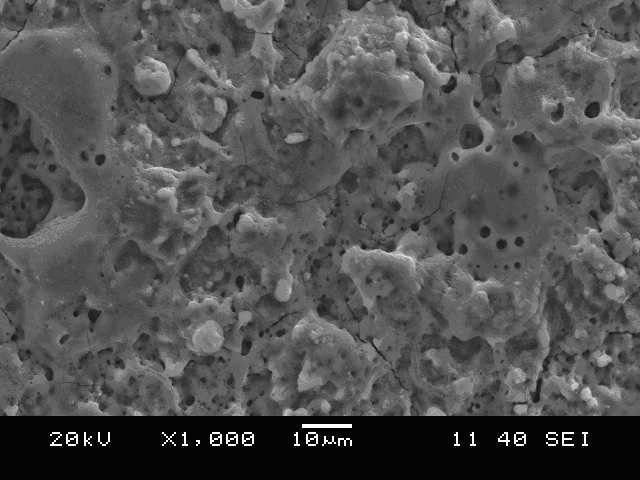

[0035] Using heteropolar pulse current power supply to prepare bio-oxidized ceramic layer, the selected parameters are: the forward current is constant at 5A, and the negative current is 0A; the forward voltage will automatically increase from 0, and finally tend to a stable value; the pulse frequency is 500Hz; The positive and negative duty cycle is 40%. The prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com