Method for treating high-calcium and high-salt industrial wastewater

A technology for industrial wastewater and a treatment method, applied in the field of water treatment, can solve problems such as undisclosed salt-containing wastewater treatment, and achieve the effect of reducing the tendency of wastewater scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

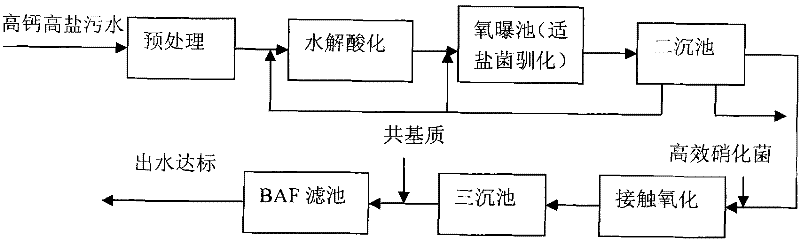

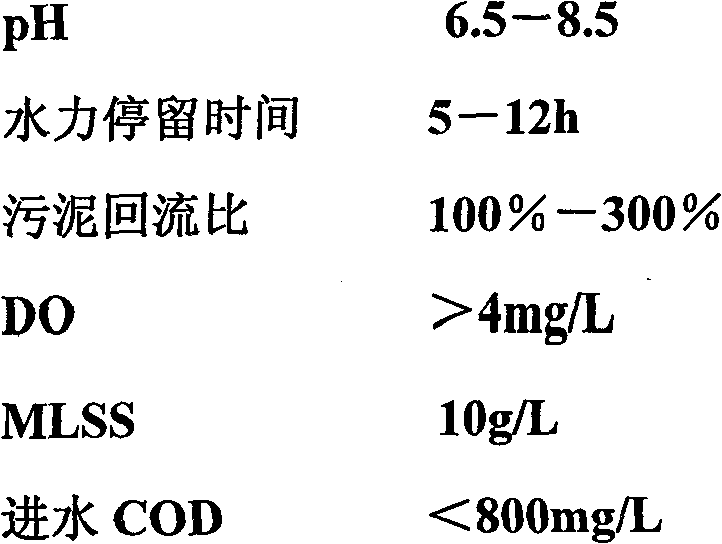

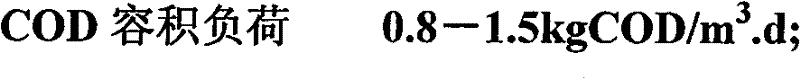

Method used

Image

Examples

Embodiment 1

[0129] Salinity content (TDS) 3.0%, COD 1250mg / L, NH 3 -The industrial waste water of N 37.6mg / L enters the high-calcium, high-salinity industrial waste water treatment system of the present invention;

[0130] a. Pretreatment system,

[0131] ①Mixed flocculation and settling unit: adding flocculant, the reaction time is 10 minutes, and the settling time is 60 minutes;

[0132] ② Pre-oxidation unit: use compressed air to aerate, control the dissolved oxygen between 1.0-2.0mg / L; adjust the pH and control the pH value between 6.0-6.5; built-in iron shavings, its porosity is 55%-95% ;

[0133] b. The hydrolytic acidification tank of the hydrolytic acidification anaerobic biochemical treatment system is divided into two sections I and II, and the structural characteristics are as follows:

[0134] ① Section I pool occupies about 3 / 5 of the volume of the pool, and adopts an intensity-controllable submerged agitator;

[0135] ②The second-stage pool accounts for about 2 / 5 of the ...

Embodiment 2

[0173] According to the method and step of embodiment 1, process index is as follows:

[0174] The salinity content (TDS) of industrial wastewater entering the system is 2.0%, COD 1126mg / L, NH 3 -N41.3mg / L,

[0175] a. Pretreatment system,

[0176] ①Mixed flocculation and settling unit: adding flocculant, the reaction time is 10 minutes, and the settling time is 120 minutes;

[0177] ② Pre-oxidation unit: use compressed air to aerate, control the dissolved oxygen between 1.0-2.0mg / L; adjust the pH and control the pH value between 6.0-6.5; built-in iron shavings, its porosity is 55%-95% ;

[0178] b. The hydrolytic acidification tank of the hydrolytic acidification anaerobic biochemical treatment system is divided into two sections I and II, and the structural characteristics are as follows:

[0179] ① Section I pool occupies about 3 / 5 of the volume of the pool, and adopts an intensity-controllable submerged agitator;

[0180] ②The second-stage pool accounts for about 2 / 5 ...

Embodiment 3

[0218] According to the method and step of embodiment 1, process index is as follows:

[0219] The salinity content (TDS) of industrial wastewater entering the system is 1.51%, COD 881.0mg / L, NH 3 -N 11.7mg / L,

[0220] a. Pretreatment system,

[0221] ①Mixed flocculation and settling unit: adding flocculant, the reaction time is 10 minutes, and the settling time is 120 minutes;

[0222] ② Pre-oxidation unit: use compressed air to aerate, control the dissolved oxygen between 1.0-2.0mg / L; adjust the pH and control the pH value between 6.0-6.5; built-in iron shavings, its porosity is 55%-95% ;

[0223] b. The hydrolytic acidification tank of the hydrolytic acidification anaerobic biochemical treatment system is divided into two sections I and II, and the structural characteristics are as follows:

[0224] ① Section I pool occupies about 3 / 5 of the volume of the pool, and adopts an intensity-controllable submerged agitator;

[0225] ②The second-stage pool accounts for about 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dissolved oxygen | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com