Calcination-free functional desulphurization gypsum putty powder for interior and exterior walls and preparation method thereof

A desulfurized gypsum, functional technology, applied in filling slurry and other directions, can solve the problems of secondary energy consumption, low cement replacement rate, high cost, and achieve the effect of long construction operation time, simplified production process and reduced production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

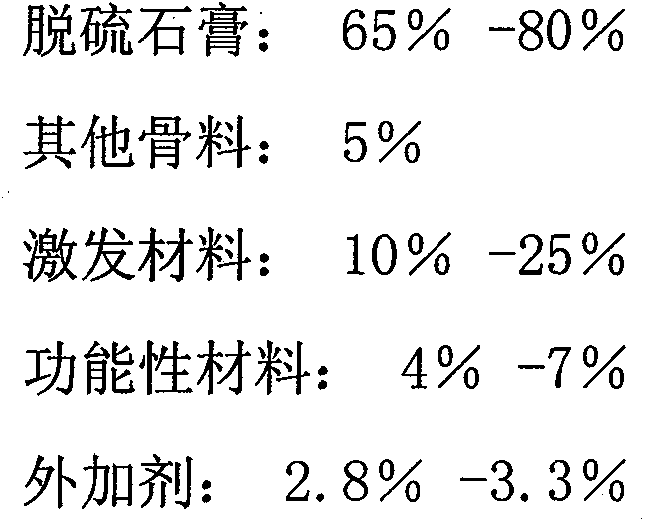

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further described below in conjunction with embodiment:

[0026] Case 1,

[0027] Take 750 kg of dihydrate desulfurized gypsum from the power plant, 50 kg of ash calcium, 50 kg of steel slag, 50 kg of talcum powder, 15 kg of latex powder, 4 kg of methyl hydroxyethyl cellulose, 3 kg of sea bath additive 3060, and 8 kg of calcined alum , 2 kg of FS-type instant sodium silicate, 50 kg of SI90-0-type mineral powder for releasing trace elements needed by the human body, 10 kg of fiber stone powder for releasing far-infrared rays (fineness is 2000 mesh), and 8 kg of anti-aging agent are mixed and stirred evenly. .

[0028] Utilize this putty powder (mass 1000 grams) to make the putty layer with a Japanese 3010 measuring instrument to measure the amount of negative ions in the air, and compare the results before and after: the amount of negative ions released reaches 2000-3000 / cm 3 .

[0029] Case 2,

[0030] Take 765 kg of dihydrate desulfurized g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com