Continuous-casting martensitic spheroidal graphite cast iron lining plate and machining process thereof

A ductile iron and processing technology, applied in the direction of grain processing, etc., can solve the problems of increasing wear, reducing the mechanical properties of the lining plate, failing to work hardening, etc., improving the corrosion resistance of grain boundaries, overcoming erosion and peeling wear, The effect of improving physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

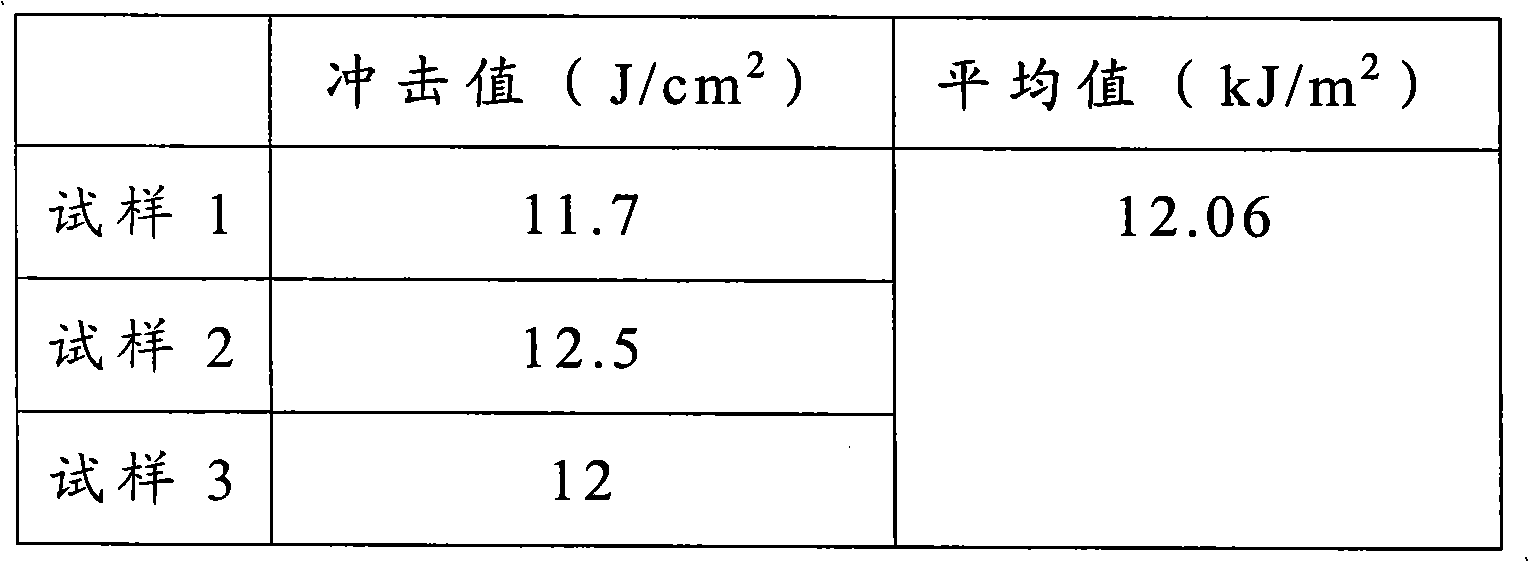

Examples

Embodiment 1

[0019] Prepare the martensitic ductile iron liner as follows:

[0020] (1) Electric furnace smelting: Send low S and P pig iron into an intermediate frequency electric furnace, heat up to 1440°C for smelting, and obtain molten iron;

[0021] (2) Spheroidization: Break the rare earth ferrosilicon-magnesium alloy into a nodulizer with a block size of 30 mm, and press ferrosilicon powder and perlite powder on the surface of the nodulizer to delay the action time of the nodulizer and molten iron To prevent nodulizers from floating up and improve the absorption rate of nodulizers, add 1.5% of the treated nodulizers into the dam specially set on the bottom side of the ladle, and then add 1 / 3 to 2% of the total amount of molten iron / 3 into the ladle, after the belt reaction is completed, pour into the rest of the molten iron and at the same time add inoculants and modifiers to the tapping trough for treatment, so as to effectively improve the shape and distribution of graphite and e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com