Liquid crystal photon crystal fiber tunable narrowband filter and manufacturing method thereof

A photonic crystal fiber, narrow-band filter technology, applied in instruments, optics, nonlinear optics, etc., can solve the problems of reduced liquid crystal utilization, enhanced liquid crystal light scattering, light energy loss, etc., to improve the utilization of liquid crystal, reduce light Loss, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

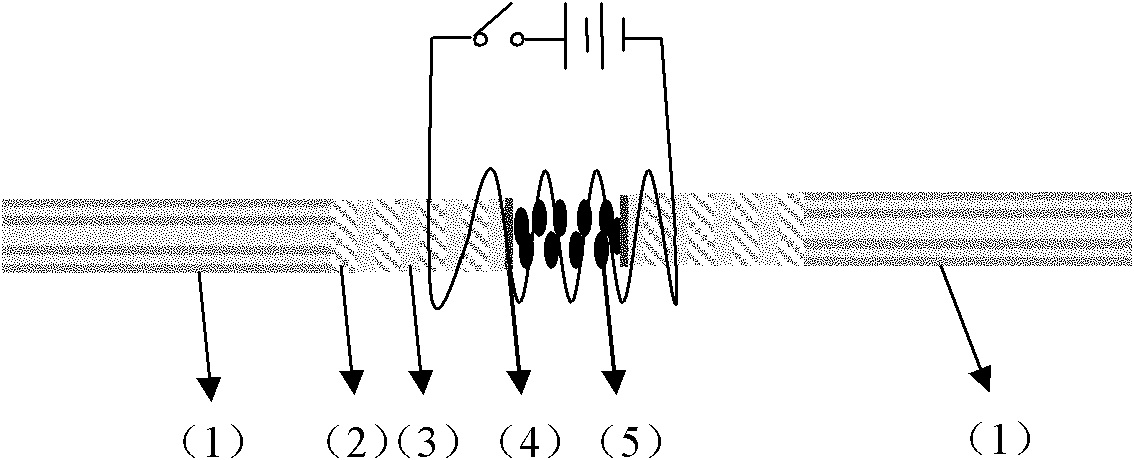

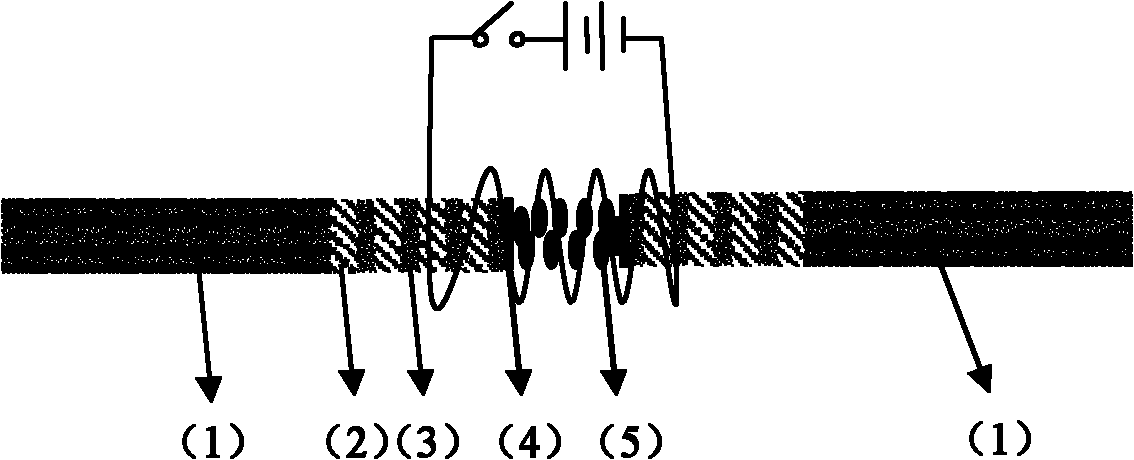

[0023] combine figure 1 , The liquid crystal photonic crystal fiber tunable narrowband filter of the present invention includes two photonic crystal fibers 1 , silicon dioxide 2 , titanium dioxide 3 , orientation film 4 , and liquid crystal 4 .

[0024] The liquid crystal photonic crystal fiber tunable narrowband filter of the present invention is prepared by such a method:

[0025] (1) Select two photonic crystal fibers with solid cores whose end face flatness is better than 10 nanometers, and use the H447700-7 box-type coating machine to alternately plate thicknesses of 265 nm and 165 nm on the end face side of the photonic crystal fiber, respectively. Nano silicon dioxide and titanium dioxide films, 5 pairs in total;

[0026] (2) Dip the end face of the photonic crystal fiber dielectric film with a concentration of 1% polyvinyl alcohol (PVA) aqueous solution, place the photonic crystal fiber in an oven at 100 degrees Celsius for 20 minutes, and then soak the end face of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com