Device and method for continuously preparing magnesium hydroxide flame retardant

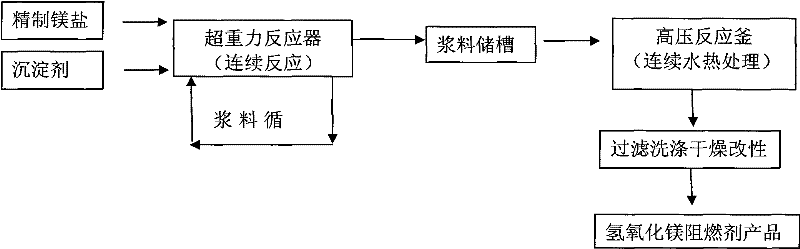

A technology of magnesium hydroxide and flame retardant, applied in magnesium hydroxide and other directions, can solve the problems of high energy consumption and complex process, and achieve the goal of reducing carbon emissions, realizing product particle size and width-thickness ratio, reducing equipment volume and investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Continuous preparation of magnesium hydroxide flame retardant using bromine production waste liquid and ammonia gas

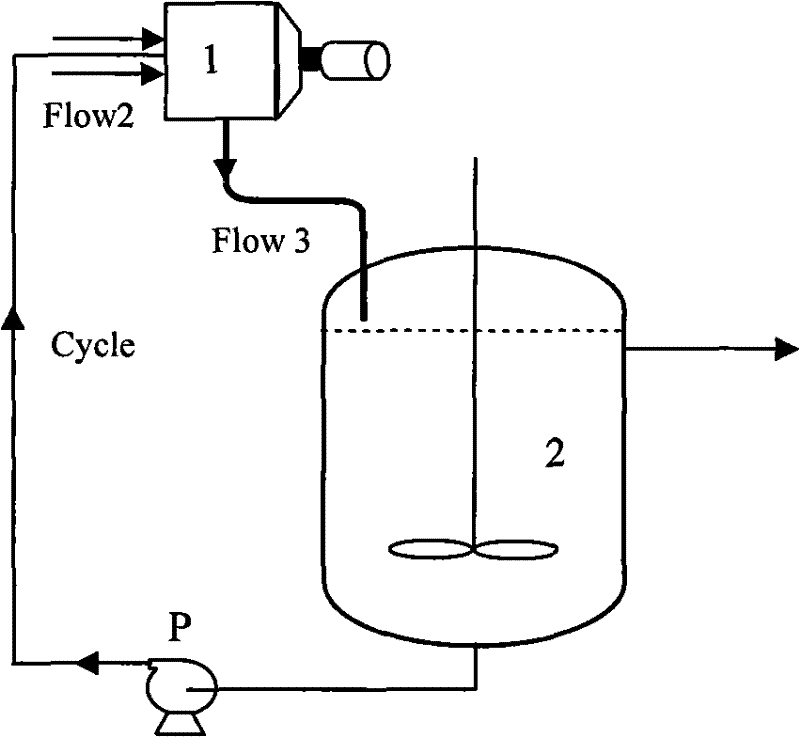

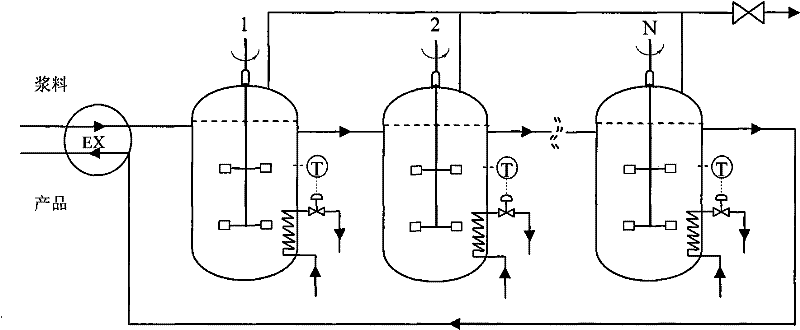

[0040] Add a small amount of activated carbon powder to the bromine production waste liquid and stir for a period of time, filter to remove the color and organic matter to obtain a clear and transparent solution, then stir and add a small amount of sodium carbonate or sodium hydroxide solution to adjust the pH to above 5.5, use a precision filter The precipitate is separated to remove iron and calcium ions to obtain a clear colorless refined magnesium chloride solution, which is diluted with water to prepare a magnesium chloride solution with a magnesium ion concentration of 2.0 mol / l. After the solution is preheated to 30°C, it is transported to the high-gravity continuous reactor with a metering pump, mixed with the circulating liquid, and reacted in reverse contact with the ammonia gas. The operating parameters are controlled: the volume ratio of the circ...

Embodiment 2

[0042] Continuous preparation of magnesium hydroxide flame retardant using bromine production waste liquid and ammonia water as raw materials

[0043] The refined magnesium chloride solution of Example 1 was diluted with water to prepare a magnesium chloride solution with a magnesium ion concentration of 2.6 mol / l, and ammonia gas evaporated from liquid ammonia was absorbed by water to prepare ammonia water with a weight ratio of 25%. After preheating the magnesium chloride solution and the ammonia water to 50℃, they are respectively transported to the high-gravity continuous reactor with a metering pump, and mixed with the circulating liquid to react. The operating parameters are controlled: the volume ratio of the circulating slurry to the continuous feed is 80:1 The reaction temperature is 55°C, the molar ratio of ammonia and magnesium is 3.5:1, and the reaction residence time is 1 hour. The magnesium hydroxide slurry is continuously discharged from the reactor and enters the b...

Embodiment 3

[0045] Continuous preparation of magnesium hydroxide flame retardant using bromine production waste liquid and lime milk as raw materials

[0046] Dilute the refined magnesium chloride solution of Example 1 with water to prepare a magnesium chloride solution with a magnesium ion concentration of 2.2 mol / l. Take the quicklime block and add it to 90°C deionized water, stir and digest for 1 hour, age at room temperature, and pass through a 200 mesh sieve , Made into Ca(OH) with a solid content of 8.0%~13.0%(w) 2 suspension. After preheating the magnesium chloride solution and the milk of lime to 80°C, they are transported to the high-gravity continuous reactor with a metering pump, and mixed with the circulating liquid to react. The operating parameters are controlled: the volume ratio of the circulating slurry to the continuous feed is 80: 1. The reaction temperature is 80°C, the calcium-magnesium molar ratio is 0.9:1, and the reaction residence time is 2 hours. The magnesium hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com