Process for preparing beta layer removing gradient hard alloy

A kind of cemented carbide and preparation process technology, applied in the field of preparation of de-beta layer gradient cemented carbide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

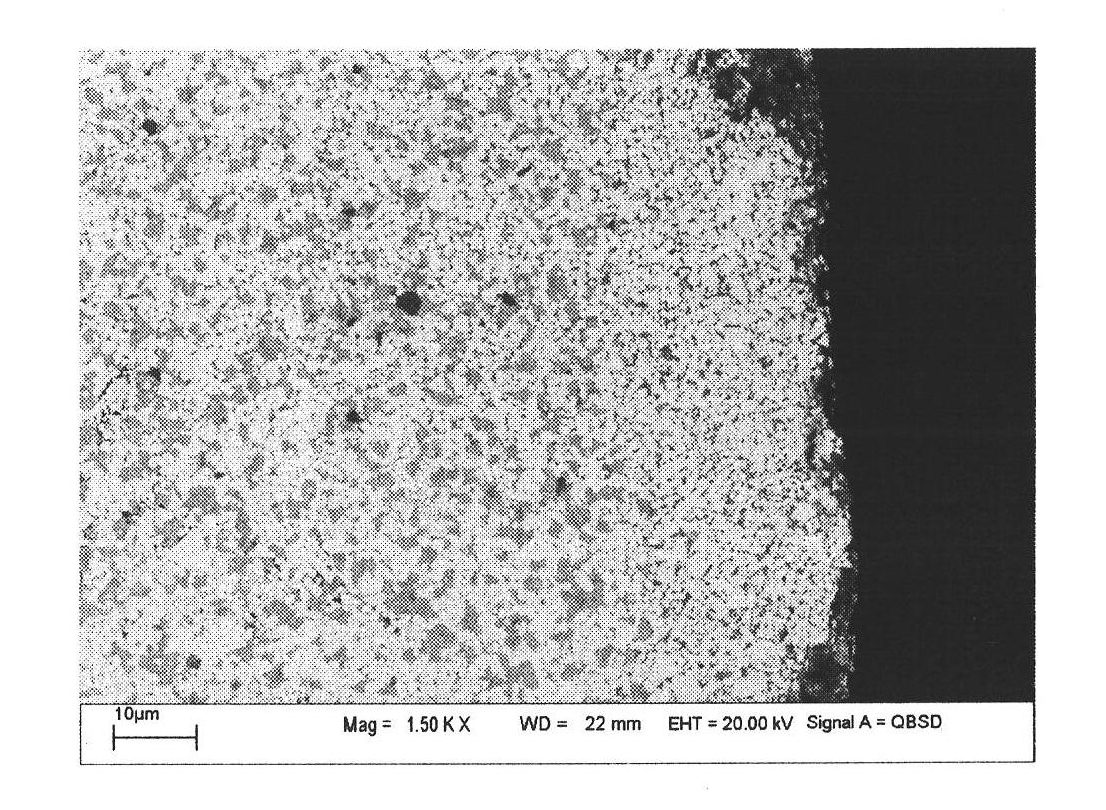

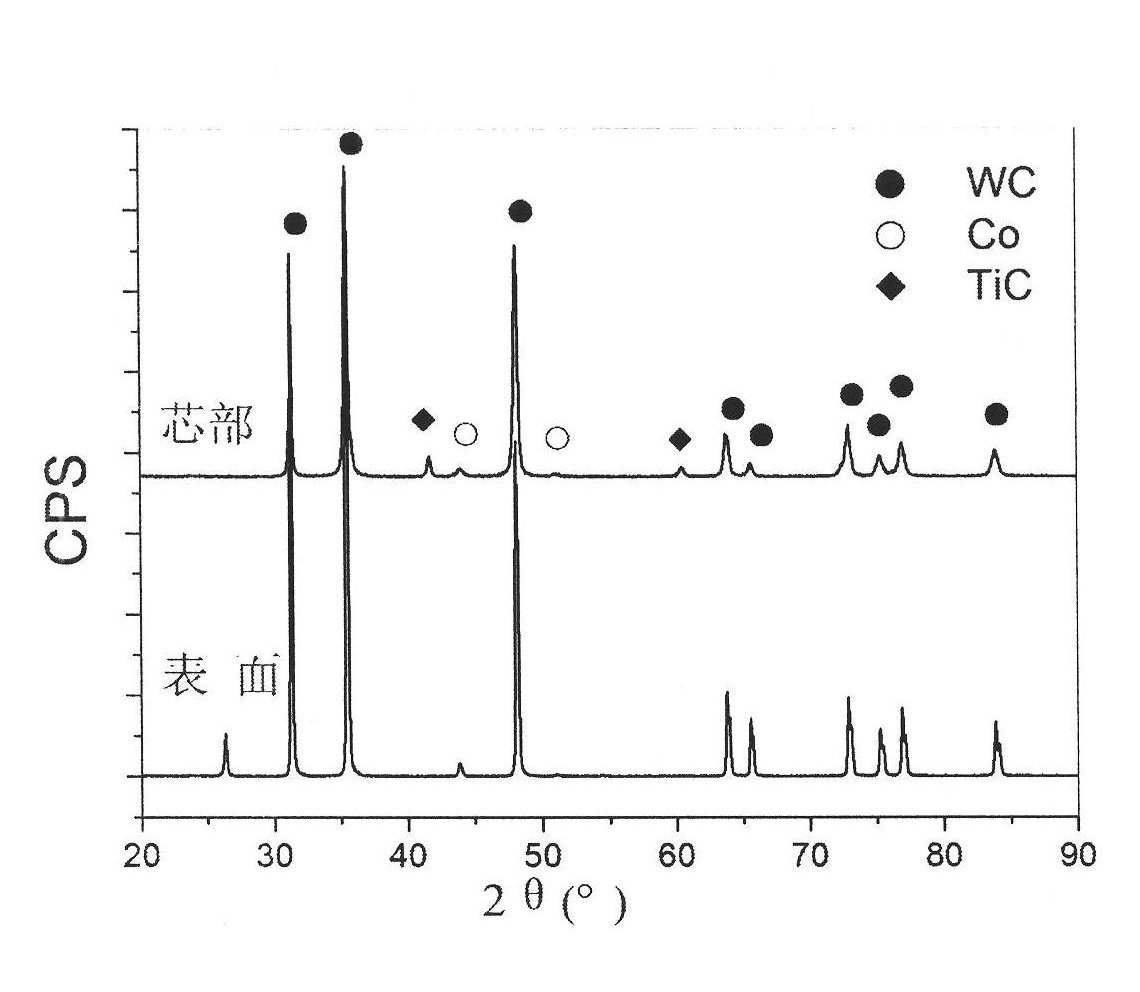

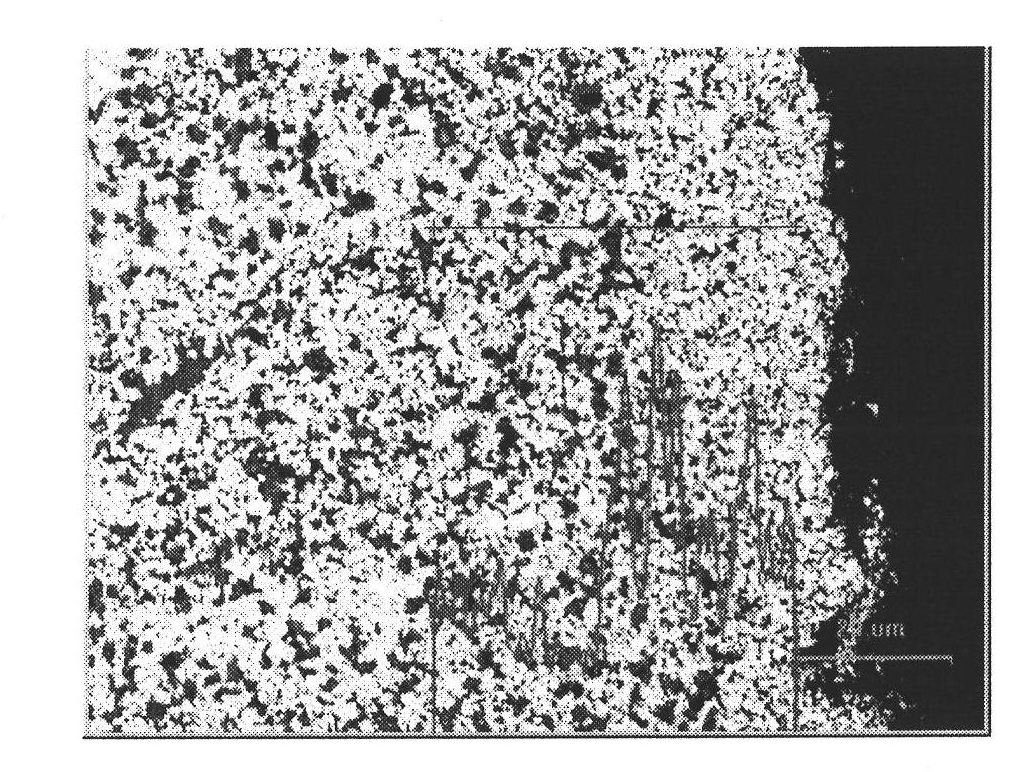

[0020] Weigh several raw material powders, and their composition ratio is (mass fraction): WC, 80.1%, (Ti, W) C, 8%, Co, 10%, carbon black, 0.3%, Ti(C, N) , 1.6%, wherein the average Fibonacci particle size of Ti (C, N) powder is 2.0 micron, C, N atomic ratio is 0.5: 0.5; After mixing raw material powder, pack into stainless steel ball mill barrel and carry out wet milling, in ball mill barrel There are cemented carbide balls with 8mm diameter, the ball-to-material ratio is 4: 1, the ball milling medium is alcohol, and the ball milling time is 36 hours; the slurry after the ball milling is carried out vacuum drying, after drying, add 2wt% paraffin gasoline solution, again After drying, crushing and sieving, the mixed material is obtained; the sample compact is molded by a press at a pressure of 200 MPa, and then vacuum sintered at a temperature of 1420°C. After 2 hours of heat preservation, the furnace cools to obtain a beta-layer gradient cemented carbide For the sample, the ...

Embodiment 2

[0022] The C of the selected Ti (C, N) powder, the atomic ratio of N is 0.7: 0.3, and the average Fischer particle size is 2.0 microns, and the composition ratio and preparation process of other raw materials are all the same as in Example 1, and finally obtained de-beta The thickness of the layer is 26 microns, and the bending strength of the substrate is 1743N / mm 2 .

Embodiment 3

[0024] The composition ratio of the raw material powder is (mass fraction): WC, 82.1%, (Ti, W) C, 8%, Co, 8%, carbon black, 0.3%, Ti (C, N), 1.6%, of which Ti The average Fischer particle size of the (C, N) powder is 2.0 microns, and the atomic ratio of C and N is 0.5:0.5; the mixture is prepared in the form of spray granulation. Finally, the thickness of the de-beta layer is 45 microns, and the bending strength of the substrate is 1872N / mm 2 .

[0025] The preparation process is the same as that of Example 1, but the examples using other alloy initial components and gradient sintering process are shown in the table below.

[0026]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average fischer particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com