Preparation method of supported nano TiO2 photocatalytic material with diatomite filter aid as carrier

A technology of photocatalytic materials and filter aids, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low utilization rate of natural light and poor thermal stability of photocatalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

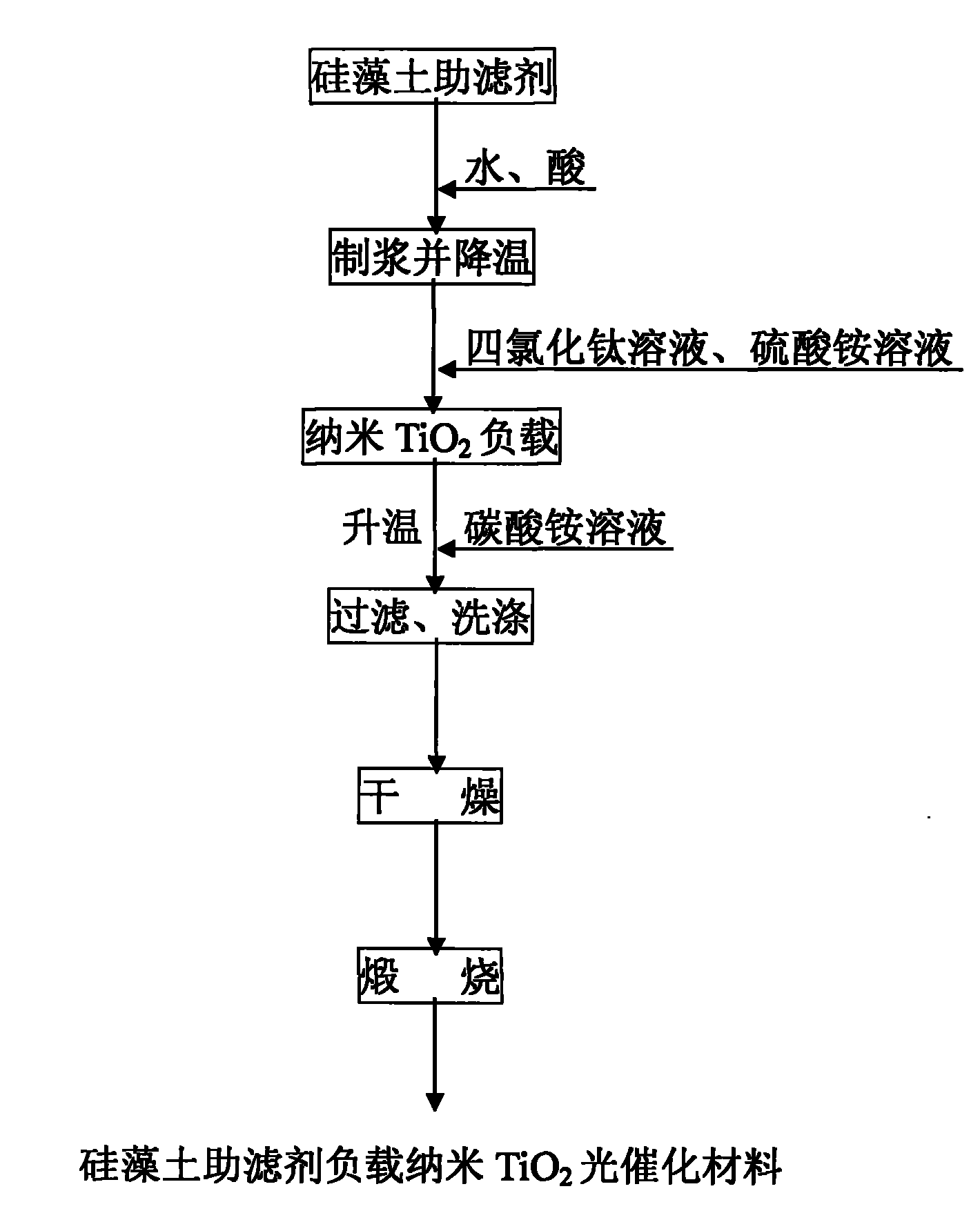

Method used

Image

Examples

Embodiment 1

[0026] Take 30kg of diatomite filter aid, add 1500L of water, adjust the pH value to 2 with hydrochloric acid, stir to disperse and cool to 5°C, then add 62L of titanium tetrachloride aqueous solution with a mass concentration of 50% and a concentration of 200g / 150L of ammonium sulfate solution in L; stir the reaction and raise the temperature to 30°C, add ammonium carbonate to adjust the pH value of the reaction solution to 5.0, and then age at 30°C for 1.0h; filter the reaction product and dry it in a flash dryer Calcined at 620-650°C for 4 hours in a continuous rotary furnace to obtain diatomite filter aid-loaded nano-TiO 2 photocatalytic material.

Embodiment 2

[0028] Take 30kg of diatomite filter aid, add 1800L of water, adjust the pH value to 2 with hydrochloric acid, stir to disperse and cool to 4°C, then add 80L of titanium tetrachloride aqueous solution with a mass concentration of 50% and a concentration of 200g / 200L of ammonium sulfate solution in L; stir the reaction and raise the temperature to 30°C, add ammonium carbonate to adjust the pH value of the reaction solution to 4.5, and then age at 30°C for 1.0h; filter the reaction product and dry it in a flash dryer Calcined at 620-650°C for 4 hours in a continuous rotary furnace to obtain diatomite filter aid-loaded nano-TiO 2 photocatalytic material.

Embodiment 3

[0030] Take 60kg of diatomite filter aid, add 1800L of water, adjust the pH value to 2 with hydrochloric acid, stir to disperse and cool to 5°C, then add 124L of titanium tetrachloride aqueous solution with a mass concentration of 50% and a concentration of 200g / 300L of ammonium sulfate solution in L; stir the reaction and raise the temperature to 28°C, add ammonium carbonate to adjust the pH value of the reaction solution to 5.0, and then age at 30°C for 1.0h; filter the reaction product and dry it in a flash dryer Calcined at 620-650°C for 4 hours in a continuous rotary furnace to obtain diatomite filter aid-loaded nano-TiO 2 photocatalytic material.

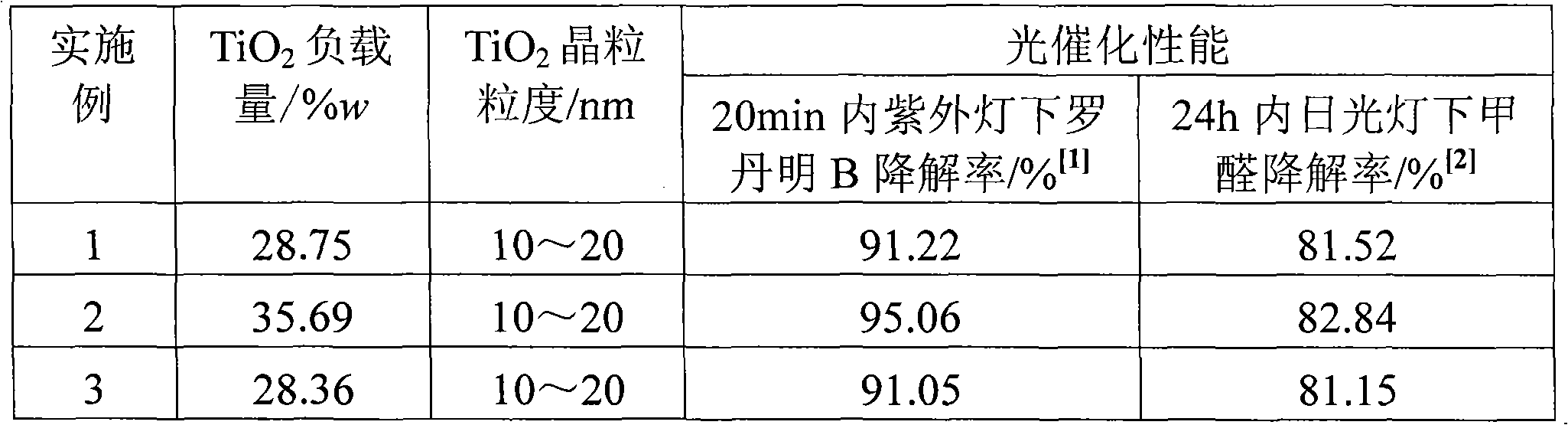

[0031] Table 1 is the detection result of the product obtained in the embodiment.

[0032] The detection analysis result of table 1 embodiment sample

[0033]

[0034] Note: [1] Add 0.1g composite material sample to 100mL rhodamine B solution with a concentration of 10mg / L;

[0035] [2]1m 3 A petri dish containing 3 μL...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| catalytic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com