Method for preparing phosphor-doped zinc oxide nanowires

A technology of zinc oxide nanowires and phosphorus doping, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems affecting the properties of zinc oxide nanowires, and achieve low cost, simple and easy process, phosphorus-containing high volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

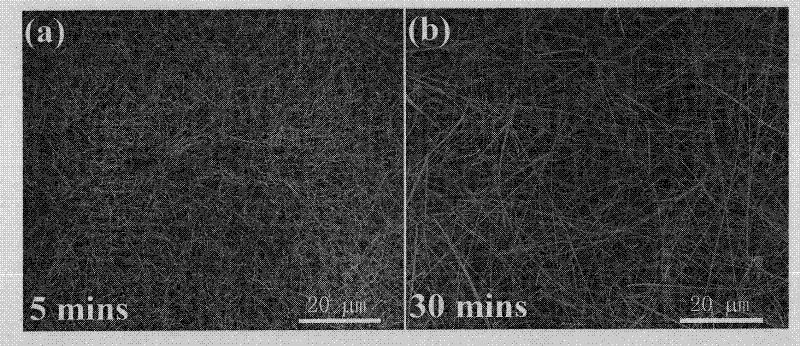

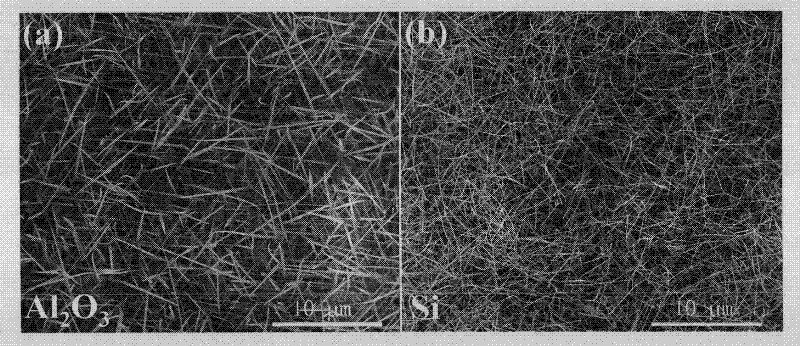

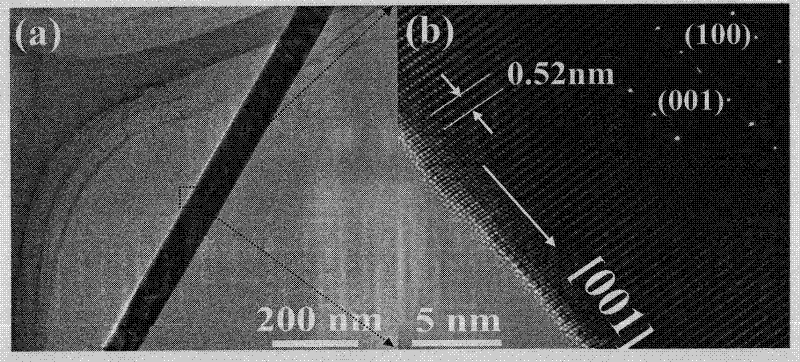

[0026] Example 1. Decompose zinc phosphate at 1050°C for 5mins to prepare phosphorus-doped zinc oxide nanowires on a silicon substrate plated with a 2nm gold catalyst film:

[0027] 1) Ultrasonic clean the silicon wafer in acetone and alcohol for 5mins, and then rinse it with deionized water. A 2nm gold catalyst film is plated on the cleaned silicon substrate by electron beam evaporation coating;

[0028] 2) Put the pure zinc phosphate powder in the aluminum oxide boat, and put the silicon chip coated with gold film directly above the zinc phosphate powder as the substrate for collecting nanowires;

[0029] 3) Push the boat with the source and the substrate into the quartz sleeve, put the quartz tube into the center of a rapid heating furnace, feed a large amount of argon to discharge the air in the tube, and then set the argon flow rate to 200sccm as carrier gas;

[0030] 4) Heat up the tube furnace to 1050°C, set the heating time to 20mins, and when the furnace temperature...

Embodiment 2

[0032] Example 2, Decompose zinc phosphate at 1050°C for 30mins to prepare phosphorus-doped zinc oxide nanowires on a silicon substrate plated with a 2nm gold catalyst film:

[0033] 1) Ultrasonic clean the silicon wafer in acetone and alcohol for 10mins, and then rinse it with deionized water. A 2nm gold catalyst film is plated on the cleaned silicon substrate by electron beam evaporation coating;

[0034] 2) Put the pure zinc phosphate powder in the ceramic boat, and place the silicon chip coated with gold film directly above the zinc phosphate powder as the substrate for collecting nanowires;

[0035] 3) Push the boat with the source and the substrate into the quartz sleeve, put the quartz tube into the center of a rapid heating furnace, feed a large amount of argon to discharge the air in the tube, and then set the argon flow rate to 200sccm as carrier gas;

[0036] 4) Heat up the tube furnace to 1050°C, set the heating time to 20mins, and when the furnace temperature re...

Embodiment 3

[0039] Example 3. Decompose zinc phosphate at 1050°C for 5mins to prepare phosphorus-doped zinc oxide nanowires on a sapphire substrate plated with a 2nm gold catalyst film:

[0040] 1) Ultrasonic cleaning of sapphire in acetone and alcohol for 5mins, and then rinse with deionized water. A 2nm gold catalyst film was plated on the cleaned sapphire substrate by electron beam evaporation coating;

[0041] 2) Put the pure zinc phosphate powder in the aluminum oxide boat, and the sapphire coated with gold film is placed directly above the zinc phosphate powder as the substrate for collecting nanowires;

[0042] 3) Push the boat with the source and the substrate into the quartz sleeve, put the quartz tube into the center of a rapid heating furnace, feed a large amount of argon to discharge the air in the tube, and then set the argon flow rate to 200sccm as carrier gas;

[0043] 4) Heat up the tube furnace to 1050°C, set the heating time to 20mins, and when the furnace temperature re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com