Nanoparticle-reinforced polyether-ether-ketone joint prosthesis material as well as preparation method and application thereof

A polyetheretherketone, nanoparticle technology, applied in medical science, prosthesis and other directions, can solve the problems of replacement joint failure, short service life, high surgical technical requirements, and achieve the effect of improving hardness and wettability and reducing wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

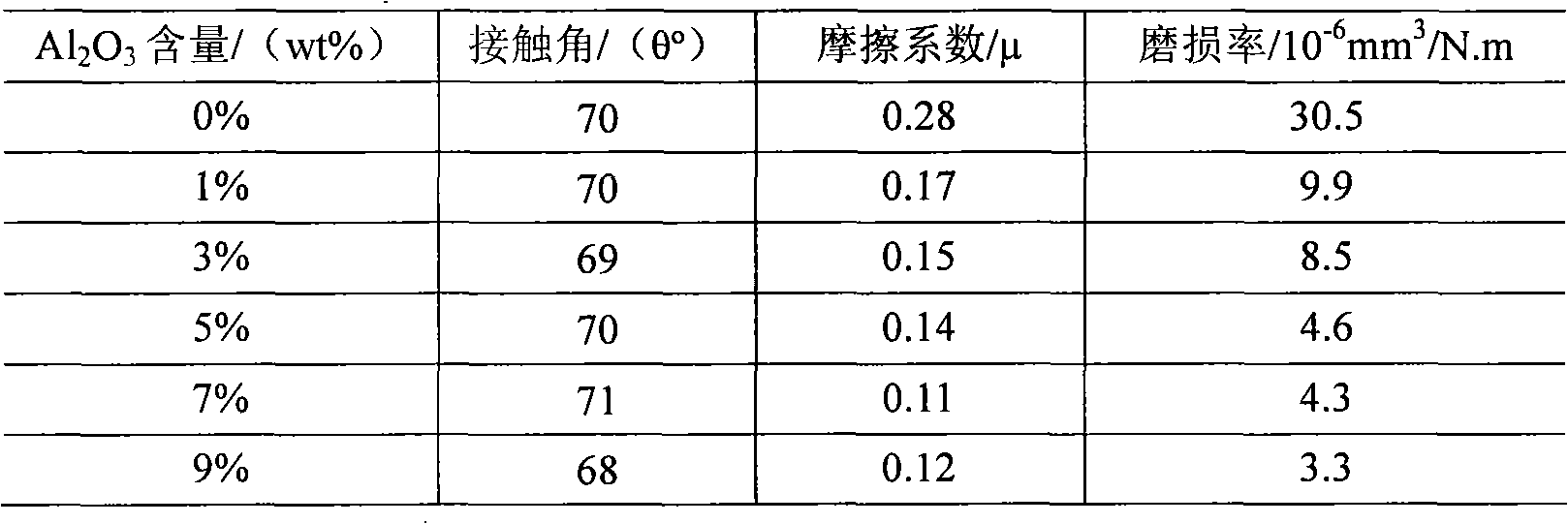

[0023] Example 1: Polyetheretherketone powder is selected, with an average particle size of 100 μm; the filling material is crystalline nano-Al 2 o 3 Powder with a purity of 99% and an average particle size of 80nm.

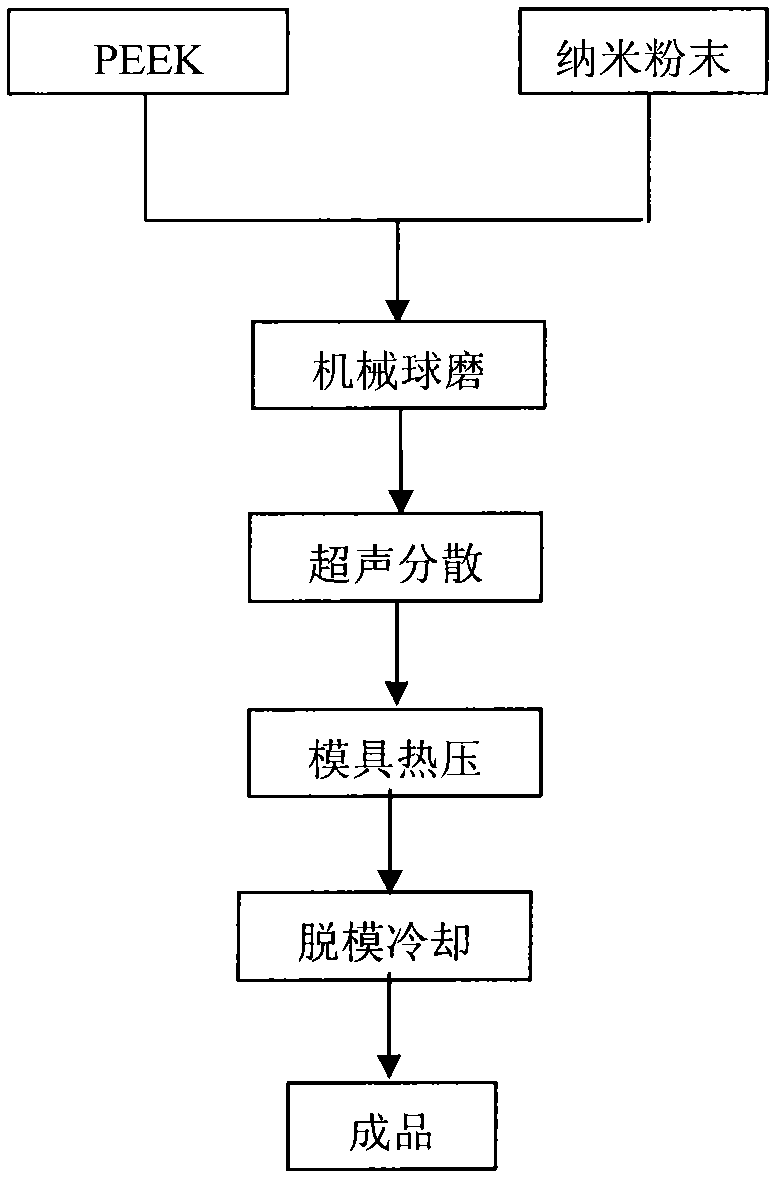

[0024] The preparation process of the composite material is as follows:

[0025] (1) Screening polyether ether ketone powder with a sieve with an aperture of 100 μm;

[0026] (2) Use stearic acid coupling agent to nanometer Al 2 o 3 Particle surface modification;

[0027] (3) the mass fraction is respectively 0%, 1%, 3%, 5%, 7%, 9% nano-Al 2 o 3 Put the powder and PEEK powder into a ball mill tank, and wet mix them under ethanol solution. The speed of the ball mill is 200 rpm, and each mixing process is clockwise and counterclockwise for 60 minutes;

[0028] (4) Ultrasonic dispersion is carried out for 10 minutes to the powder after wet mixing, and then dried in a drying oven;

[0029] (5) Pour the mixed powder into the mold cavity, about 40 grams each ti...

Embodiment 2

[0033] Example 2: Select polyether ether ketone powder, the average particle size is 100 μm; the filling material is crystal nano-Al 2 o 3 Powder with a purity of 99% and an average particle size of 20nm.

[0034] The preparation process of the composite material is as follows:

[0035] (1) Screening polyether ether ketone powder with a sieve with an aperture of 100 μm;

[0036] (2) Use stearic acid coupling agent coupling agent to nanometer Al 2 o 3 Particle surface modification;

[0037] (3) the mass fraction is respectively 0%, 1%, 3%, 5%, 7%, 9% nano-Al 2 o 3 Put the powder and PEEK powder into a ball mill tank, and wet mix them under ethanol solution. The speed of the ball mill is 200 rpm, and each mixing process is clockwise and counterclockwise for 60 minutes;

[0038] (4) Ultrasonic dispersion is carried out for 10 minutes to the powder after wet mixing, and then dried in a drying oven;

[0039] (5) Pour the mixed powder into the mold cavity, about 40 grams eac...

Embodiment 3

[0043] Example 3 selects polyether ether ketone powder, with an average particle size of 100 μm; the filling material is crystal nano-Al 2 o 3 Powder with a purity of 99% and an average particle size of 100nm.

[0044] The preparation process of the composite material is as follows:

[0045] (1) Screening polyether ether ketone powder with a sieve with an aperture of 100 μm;

[0046] (2) Use stearic acid coupling agent coupling agent to nanometer Al 2 o 3 Particle surface modification;

[0047] (3) the mass fraction is respectively 0%, 1%, 3%, 5%, 7%, 9% nano-Al 2 o 3 Put the powder and PEEK powder into a ball mill tank, and wet mix them under ethanol solution. The speed of the ball mill is 200 rpm, and each mixing process is clockwise and counterclockwise for 60 minutes;

[0048] (4) Ultrasonic dispersion is carried out for 10 minutes to the powder after wet mixing, and then dried in a drying oven;

[0049] (5) Pour the mixed powder into the mold cavity, about 40 grams ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com