Method for preparing doped barium titanate powder through wet process

A barium titanate powder, barium titanate technology, applied in chemical instruments and methods, titanium compounds, inorganic chemistry, etc., can solve the problems such as gel precipitate drying and anti-hard agglomeration that are not proposed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

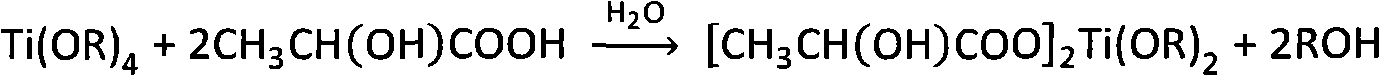

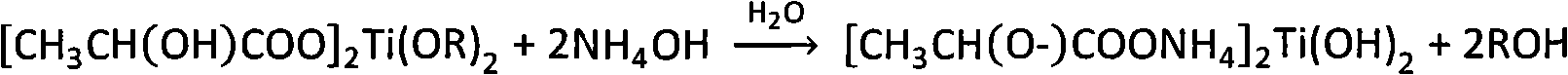

Method used

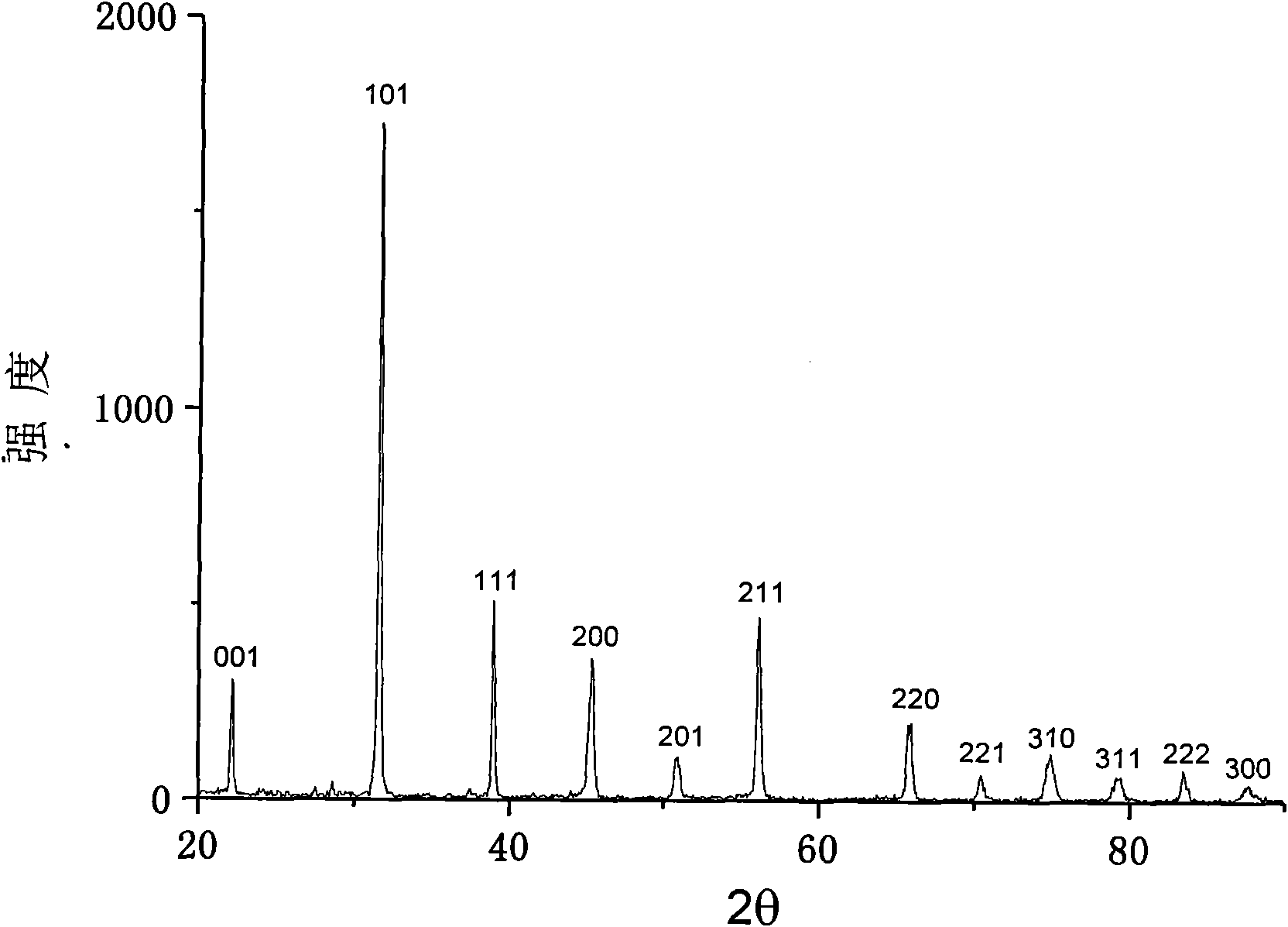

Image

Examples

Embodiment 1

[0086] The doped barium titanate of the present embodiment is (Ba 0.9575 Gd 0.0025 Ca 0.04 )[Ti 0.815 mn 0.0025 Y 0.0025 Zr 0.18 ] 0.997 o 3 . First deionized water was boiled for 20 minutes, and cooled for later use; 61.1788 grams of titanium isopropoxide (98%) were weighed in a nitrogen protection box, then 58 milliliters of lactic acid (85%) was added, and an appropriate amount of deionized water was added after fully stirring. React at 60°C for 4 hours; dissolve 10.7729 g of zirconyl nitrate in 40 ml of deionized water at 50°C, add 9 ml of lactic acid (85%), stir well, and then pour the formed white suspension into titanium isopropoxide and the reaction solution of lactic acid, stir and mix evenly; add 80.0185 grams of Ba(OH) 2 ·8H 2 O (98%) and 0.8099 g Ca(OH) 2 (95%), reacted for 8 hours at 50°C; then added 0.1586 gram of Mn(CH 3 COO) 2 4H 2 O, 0.2478 g Y (NO 3 ) 3 ·6H 2 O and .0.2929 g Gd(NO 3) 3 ·6H 2 0, add water and dilute to 300 milliliters, stir...

Embodiment 2

[0088] Compared with embodiment 1, the differences of this embodiment are:

[0089] Weigh 42 grams (NH 4 ) 2 C 2 o 4 ·H 2 O, make an ammonium oxalate solution with a temperature of 80°C and a mass concentration of 18.2%, then add 0.110 grams of nonionic surfactant APG; while stirring, slowly pour the metal ion precursor solution A2 whose temperature is raised to 80°C Oxalic acid solution to form a precipitate; vacuum filter, wash 4 times with deionized water containing 0.05% polyethylene glycol, and wash 3 times with absolute ethanol; put the precipitated filter cake in an ordinary drying oven, bake at 85°C for 20 hours; place in Incubate in a muffle furnace at 350°C for 120 minutes and at 550°C for 4 hours, take out the powder and grind it, then heat at 800°C for 180 minutes to obtain doped barium titanate powder.

Embodiment 3

[0091] The doped barium titanate of the present embodiment is (Ba 0.9575 Nd 0.0025 Ca 0.04 )[Ti 0.815 mn 0.0025 Er 0.0025 Zr 0.18 ] 0.997 o 3 . First deionized water was boiled for 20 minutes, cooled for later use; 44 milliliters of lactic acid (85%) was added to 80.2520 grams of tetrabutyl titanate (99%), after fully stirring, deionized water was added to adjust the total volume of the solution to 200 milliliters, React at 50°C for 6 hours; dissolve 11.9210 g of zirconyl nitrate in 40 ml of deionized water at 50°C, add 10 ml of lactic acid (85%), stir well and then pour the formed white suspension into tetrabutyl titanate The reaction solution of ester and lactic acid, stirring and mixing; add 88.5464 grams of Ba (OH) 2 ·8H 2 O (98%) and 0.8962 g Ca(OH) 2 (95%), reacted for 3 hours at 90°C; then added 0.1754 gram of Mn(CH 3 COO) 2 4H 2 O, 0.3174 grams of Er(NO 3 ) 3 ·5H 2 O and 0.3266 g Nd(NO 3 ) 3 ·nH 2 O(37%Nd 2 o 3 ), diluted with water to 400 ml, sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com