Multiple-effect membrane distillation method with high-efficiency inner heat recovering function

A multi-effect membrane distillation and heat recovery technology, which is applied in the fields of energy wastewater treatment, heating water/sewage treatment, etc., can solve problems such as unspecified experimental data, and achieve simple operation, high water production ratio, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Feed liquid: a sodium chloride (NaCl) aqueous solution with a salt concentration of 3% by weight, which is equivalent to the salt concentration in the original seawater from seawater desalination.

[0053] Feed liquid feed temperature: 25~30℃

[0054] Heat source: hot water with a temperature of 98-100°C

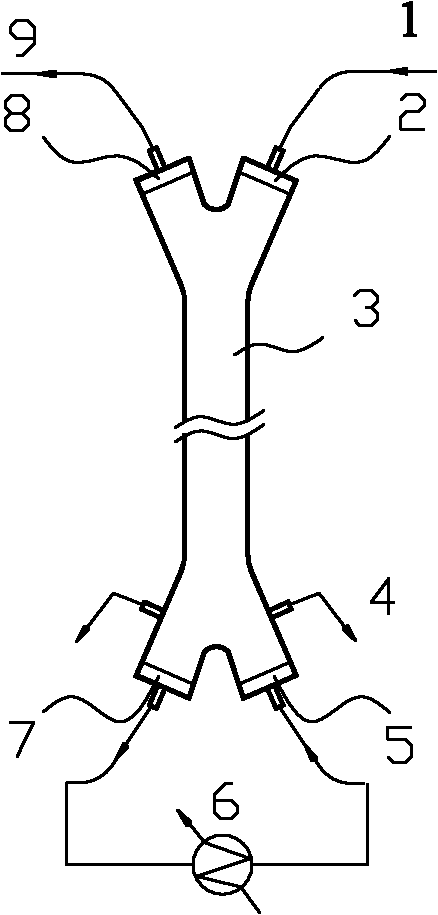

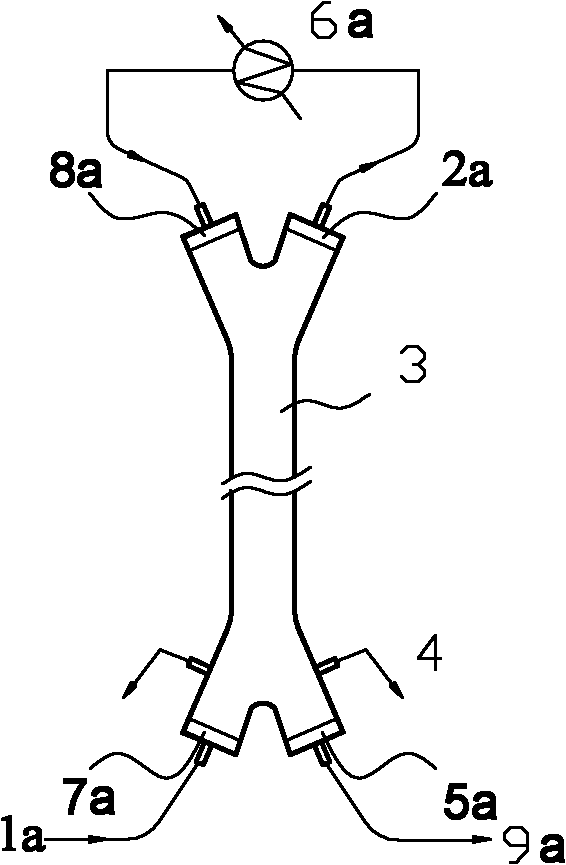

[0055] Mode of operation: use figure 2 The cold feed method shown for the multi-effect membrane distillation process

[0056] Experimental results:

[0057] The water flux of the multi-effect hollow fiber membrane module is: 6.28L / (m 2 h).

[0058] The water making ratio is: 12.5.

[0059] The conductivity of distilled water is: 3.2μs / cm.

Embodiment 2

[0061] Feed liquid: a sodium chloride (NaCl) aqueous solution with a salt concentration of 6% by weight, which is equivalent to the salt concentration in the by-product concentrated brine produced in the traditional seawater desalination process.

[0062] Feed liquid feed temperature: 25 ~ 30 ℃.

[0063] Heat source: hot water with a temperature of 98-100°C.

[0064] Mode of operation: use figure 2 The cold-feed approach shown is for a multi-effect membrane distillation process.

[0065] Experimental results:

[0066] The water flux of the multi-effect hollow fiber membrane module is: 5.88L / (m 2 h).

[0067] The water making ratio is: 10.4.

[0068] The conductivity of distilled water is: 7.2μs / cm.

Embodiment 3

[0070] Feed liquid: the weight percent concentration of salt is 15% sodium chloride (NaCl) aqueous solution.

[0071] Feed liquid feed temperature: 95 ~ 100 ℃.

[0072] Cold source: ground water.

[0073] Mode of operation: use figure 1 The hot feed mode shown carries out the multi-effect membrane distillation process.

[0074] Experimental results:

[0075] The water flux of the multi-effect hollow fiber membrane module is: 4.20L / (m 2 h)

[0076] The water making ratio is: 7.6.

[0077] The conductivity of distilled water is: 10.2μs / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water flux | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Water flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com