Method for preparing benzoxazole functionalized graphene hybrid materials

A benzoxazole-based, functionalized technology, applied in the direction of fibrous fillers, etc., can solve the problems of preparing composite materials, no benzoxazole-based hybrid materials, and inability to disperse, and achieve excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

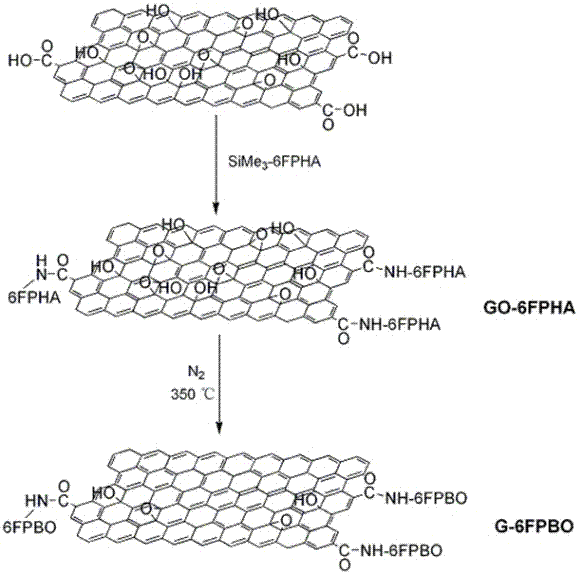

[0024] Example 1 (see attached figure 1 )

[0025] The specific steps of the preparation method of the benzoxazole functionalized graphene hybrid material are:

[0026] (1) Prepare single-layer or multi-layer graphite oxide from natural graphite according to the prior art chemical oxidation method (the document is: J. Am. Chem. Soc., 1958, 80, 1339);

[0027] (2) Under the condition of 70 ℃, under the protection of nitrogen, the monolayer graphite oxide obtained in step (1) was reacted with excess thionyl chloride and a small amount of catalyst DMF for 24 hours, and then the excess thionyl chloride was distilled off, Acyl chlorinated graphite oxide (GO-Cl);

[0028] (3) Silylation of 4,6-diaminoresorcinol hydrochloride (4.8 mmol) with N,O-bistrimethylsilylacetamide (10 mmol), and then with terephthaloyl chloride (4.0 mmol) was polycondensed using an ice-water bath at 0 °C to obtain amino-terminated silylated hydroxyamides (SiMe 3 -PHA);

[0029] (4) Mix 50 mg of the aci...

Embodiment 2

[0033] The specific steps of the preparation method of the benzoxazole functionalized graphene hybrid material are:

[0034] (1) (same as embodiment 1);

[0035] (2) (same as embodiment 1);

[0036] (3) Use N,O-bistrimethylsilylacetamide (10mmol) to silanize 2,2-bis(3-amino-4-hydroxyphenyl)hexafluoropropane (4.8 mmol), and then react with p-benzene Diformyl chloride (4.0 mmol) was subjected to polycondensation at 0 °C to obtain amino-terminated silylated hydroxyamides (SiMe 3 -6FPHA);

[0037] (4) GO-Cl (50 mg) obtained in step (2) and SiMe obtained in step (3) 3 -6FPHA (0.53 mmol amino equivalent) was blended in anhydrous DMF, sonicated for 30 min and reacted at 60 °C for 72 hours in a nitrogen atmosphere;

[0038] (5) Pour the reaction solution into the mixed solution of water and methanol with a mixing ratio of 1:1, filter with a 0.22 μm membrane, and repeat the following operations for the obtained filter cake three times: ultrasonically dissolve with DMF, mix with wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com