Method for preparing polyvinylidene fluoride hollow fiber membrane

A technology of polyvinylidene fluoride and its manufacturing method, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of high energy consumption, complex process, poor elasticity, etc., and achieve improved elongation and improved Effect of high density, porosity, and high tensile elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

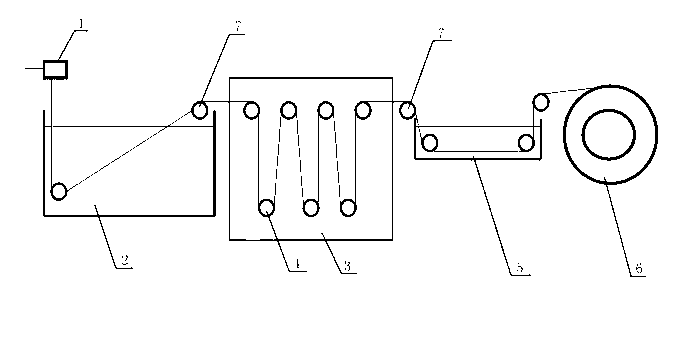

[0041] The raw materials are weighed according to the following weight percentages: 33.5% of PVDF, 55% of dimethylacetamide, 8% of ethylene glycol, 3% of polyvinylpyrrolidone, and 0.5% of dioctyl phthalate, and the specific order is: Add PVDF to dimethylacetamide, stir and dissolve, add polyvinylpyrrolidone, ethylene glycol and dioctyl phthalate together, the temperature of the membrane liquid is 40°C, continue to stir well, then filter the membrane liquid to remove air bubbles After cleaning, such as figure 1 As shown, the 70°C membrane liquid and the inner gel medium, that is, 5% dimethylacetamide aqueous solution at 70°C, are simultaneously injected into the 1# outer gel medium, that is, 14.5% carbonic acid at 75°C, through the annular spinneret 1. In the 1# gel bath 2 of the acrylic ester aqueous solution, the sprayed silk is gradually exchanged in the 1# outer gel medium, and then introduced into the drawing box 3 through the godet wheel 7, and drawn with 7 drawing wheels...

Embodiment 2

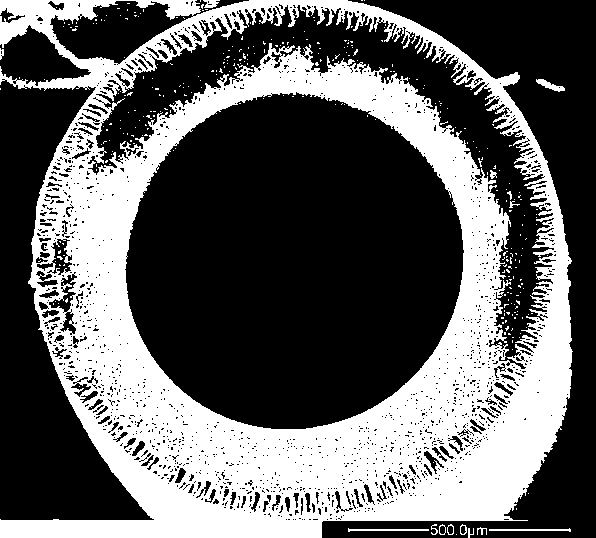

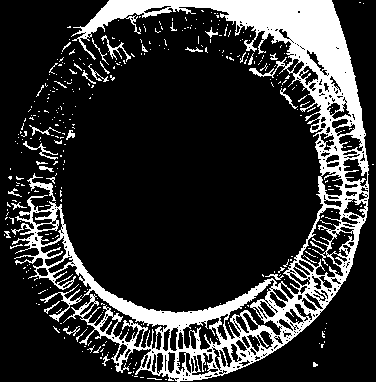

[0043] According to the preparation process and technology described in Example 1, wherein the membrane liquid consists of: PVDF 10.8%, dimethylacetamide 83%, glycerol 5%, polyvinylpyrrolidone 1%, dioctyl phthalate 0.2 %, the stirring and mixing temperature is 85°C. The temperature of the membrane-making solution obtained was 86.5°C, and the inner gel medium was changed to 25°C desalted water, and the 1# outer gel medium was a mixture of 70% propylene carbonate and 13% butyrolactone by mass percentage, The temperature is 30°C, drawing at a speed of 8m / min, and the 2# outer gel medium is also desalted water, wound to the winding wheel at a speed of 15m / min, and other process conditions are the same as in Example 1, and the into PVDF hollow fiber membrane filaments. The obtained membrane filament has an outer diameter of 1.43 mm, an inner diameter of 0.72 mm, a porosity of 88%, a pure water flux of 950 L / m2 h (0.1 Mpa, 25 °C), a tensile burst strength of 1.13 Mpa, and a tensile...

Embodiment 3

[0045] According to the preparation process and technology described in Example 1, wherein the membrane liquid consists of: PVDF 23.7%, dimethylformamide 73%, polyvinylpyrrolidone 2%, n-butanol 1%, dioctyl phthalate 0.3 %, stirring and mixing temperature is 65°C. The temperature of the obtained film-making membrane solution is 40°C, the inner gel is changed to 60% dimethylformamide aqueous solution, and the temperature is controlled at 25°C, the 1# gel medium is 60% butyrolactone solution, and the temperature is 38°C. Drawing at a speed of 28m / min, the 2# outer gel is desalted water, the temperature is 25°C, and it is wound to the winding wheel at a speed of 40m / min. Other process conditions are the same as in Example 1, and it can be made PVDF hollow fiber membrane. The obtained membrane filament has an outer diameter of 1.15 mm, an inner diameter of 0.53 mm, a porosity of 90%, a pure water flux of 750 L / m2 h (0.1 Mpa, 25 °C), a tensile burst strength of 1.8 Mpa, and a tensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com