Polyurethane heat-insulation structural adhesive and manufacturing method for heat-insulation aluminum profile

A manufacturing method and polyurethane technology are applied in the field of aluminum alloy doors and windows, and architectural aluminum alloy profiles for curtain walls, which can solve the problems affecting the popularization and use of castable heat insulation technology, difficulty in obtaining castable aluminum profiles, and unsatisfactory mechanical properties. Achieve low rejection rate, excellent mechanical properties, wear resistance and stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

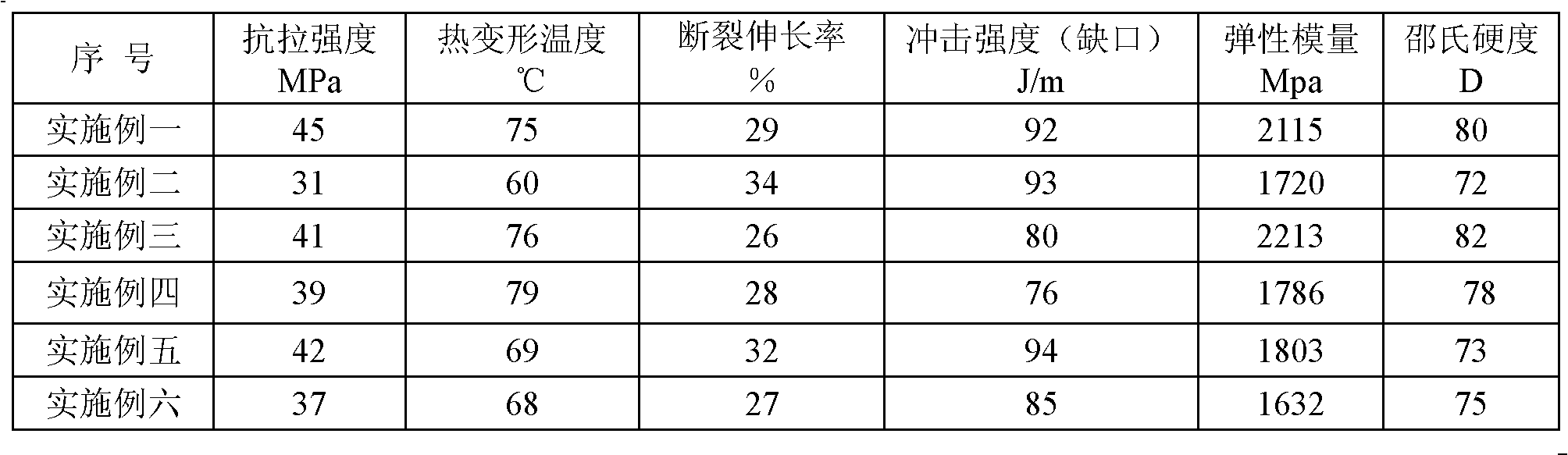

Examples

Embodiment 1

[0025] The polyurethane thermal insulation structural adhesive in this embodiment is composed of components A and B, and the mass ratio of components A and B is 100:80. The proportioning of each component and mass parts is as follows:

[0026] A component

[0027] Polyether polyol

[0028] Catalyst stannous octoate 0.1% (accounting for the mass ratio of polyether polyol, the same below)

[0029] Leveling agent organic fluorosilicon compound 0.25%

[0030] Defoamer organic fluorosilicon compound 0.1%

[0031] Chain extender TMP 0.6%

[0032] Chain extender MDA 0.6%

[0033] Filler quartz powder 1%

[0034] Plasticizer dibutyl phthalate 3%

[0035] Antioxidant IRGANOX 1010 0.3%

[0036] UV absorber TINUVIN P 0.1%

[0037] Antifungal agent 0.1%

[0038] Wherein the polyether polyol is a mixture of polyoxyethylene ether and / or polyethylene glycol, such as starting from glycerin, copolymerized polyol of propylene oxide and ethylene oxide, random or end-capped copolymeriza...

Embodiment 2

[0048]The difference between this example and Example 1 is that the polyurethane thermal insulation structural adhesive in this example has a mass ratio of components A and B of 100:70, and component B is liquid MDI and 2,4'-MDI according to 1:1 mass ratio mixture. The manufacturing method step 1) is cooled and then solidified at room temperature for 20 seconds; in step 3), the material is poured into the groove of the aluminum profile moving at a speed of 0.35 m / s, and cooled and solidified for 20 hours. Obtain the polyurethane heat-insulating adhesive composite aluminum profile of straight shape.

Embodiment 3

[0050] The difference between this embodiment and the first embodiment lies in that the mass ratio of the components A and B of the polyurethane thermal insulation structural adhesive in this embodiment is 100:90.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com