Method for biologically inhibiting production of secondary hydrogen sulfide from sulfate reducing bacteria in crude oil gathering and transporting system

A collection and transportation system, bioinhibition technology, applied in botany equipment and methods, chemicals for biological control, biocides, etc., can solve human injury, reduced sterilization efficiency, drug resistance of sulfate-reducing bacteria, etc. problem, to achieve the effect of low cost and time restraint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The concentration of hydrogen sulfide is 239mg / m 3 Take the Guan Yi Zhuan Zhuan oil station as an example.

[0022] (1) Biological inhibitor consists of 12mg / L borate, 23mg / L hydroxide electrolyte, 45mg / L nitrate + 25mg humic acid.

[0023] (2) The dosing point is the oil transfer station, and the dosing position is the dosing tank at the entrance of the station; the amount of biological preparations added to each liter of crude oil is 80mg / L; The pump continuously adds medicine for 24 hours, and the flow rate of the dosing pump is 0.27L / h.

[0024] (3) Monitoring sampling point: the breathing zone of the measuring port of the oil storage tank; test method: use methylene blue spectrophotometry to test hydrogen sulfide.

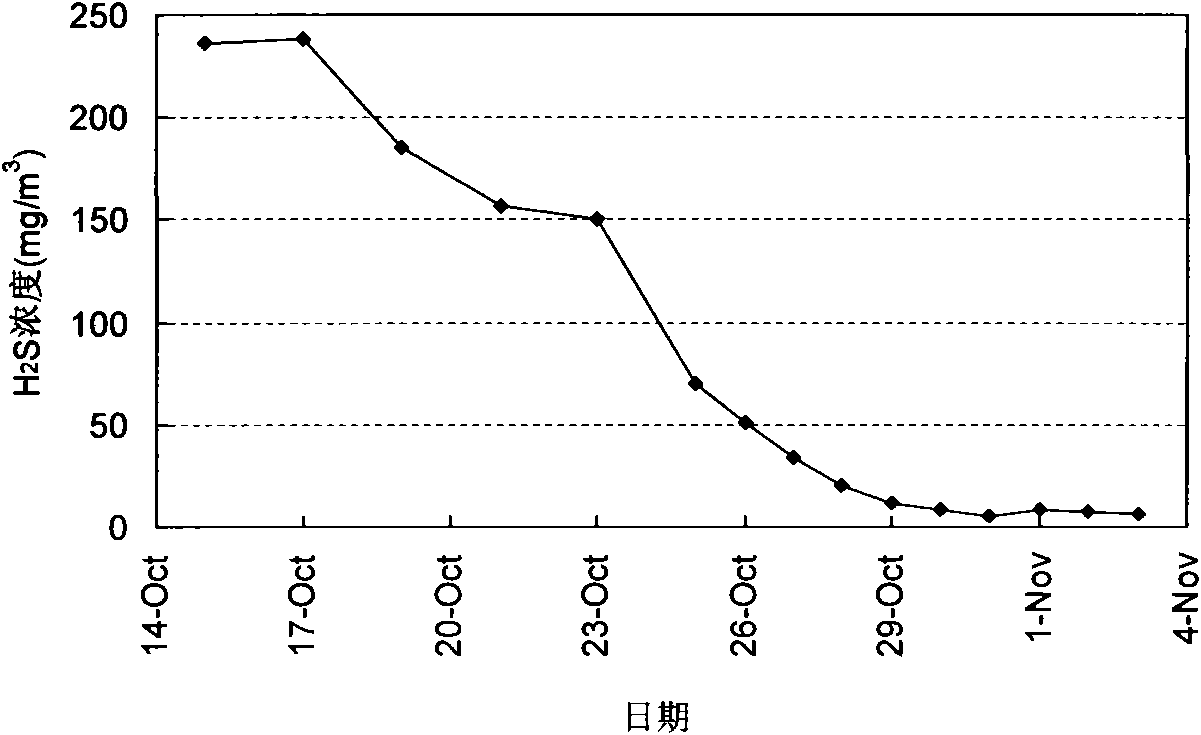

[0025] (4) Implementation effect: before the implementation, the concentration of hydrogen sulfide in the breathing zone of the oil storage tank of the Guanyizhuan oil transfer station was determined to be 239mg / m 3 15 days after the addition of biol...

Embodiment 2

[0027] The concentration of hydrogen sulfide is 151mg / m 3 single well as an example.

[0028] (1) The biological inhibitor is composed of 50mg / L sodium nitrite and 20mg / L sodium borate;

[0029] (2) The dosing point is a single well; the dosing position is the single well annulus space, and the dosing is added in the direction indicated by the arrow through the connection port of the single well annulus space; the dosing method is intermittent dosing, and the intermittent period is 30 days / time, each dosing amount is calculated as follows:

[0030] Dosing amount each time = 30×dosing concentration×crude oil production+dosing concentration×casing volume×(artificial bottom hole depth-dynamic fluid surface depth)

[0031] Among them: Crude oil production: 5.16 cubic meters / d Artificial well bottom depth: 1594.28m

[0032] Depth of dynamic liquid surface; 1382m Casing volume = 12.7×10 -3 m 3

[0033] The dosage calculated by the above formula is 10.839kg each time.

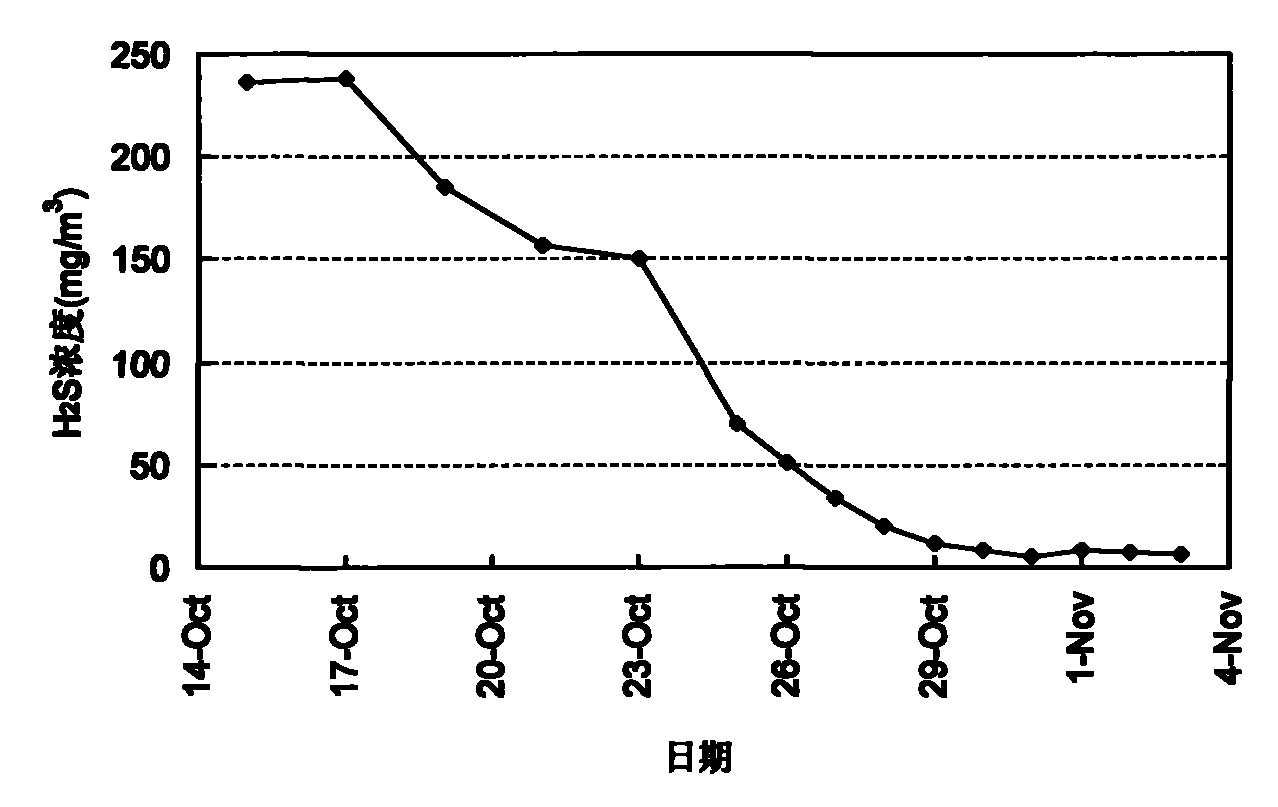

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com