Chemical senor, method and application on basis of laser effects in fluorescence conjugated polymer

A conjugated polymer and chemical sensor technology, applied in the field of chemical sensing, can solve the problems of low fluorescence intensity and wide spectrum, and achieve the effects of wide application prospects, high sensitivity, and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

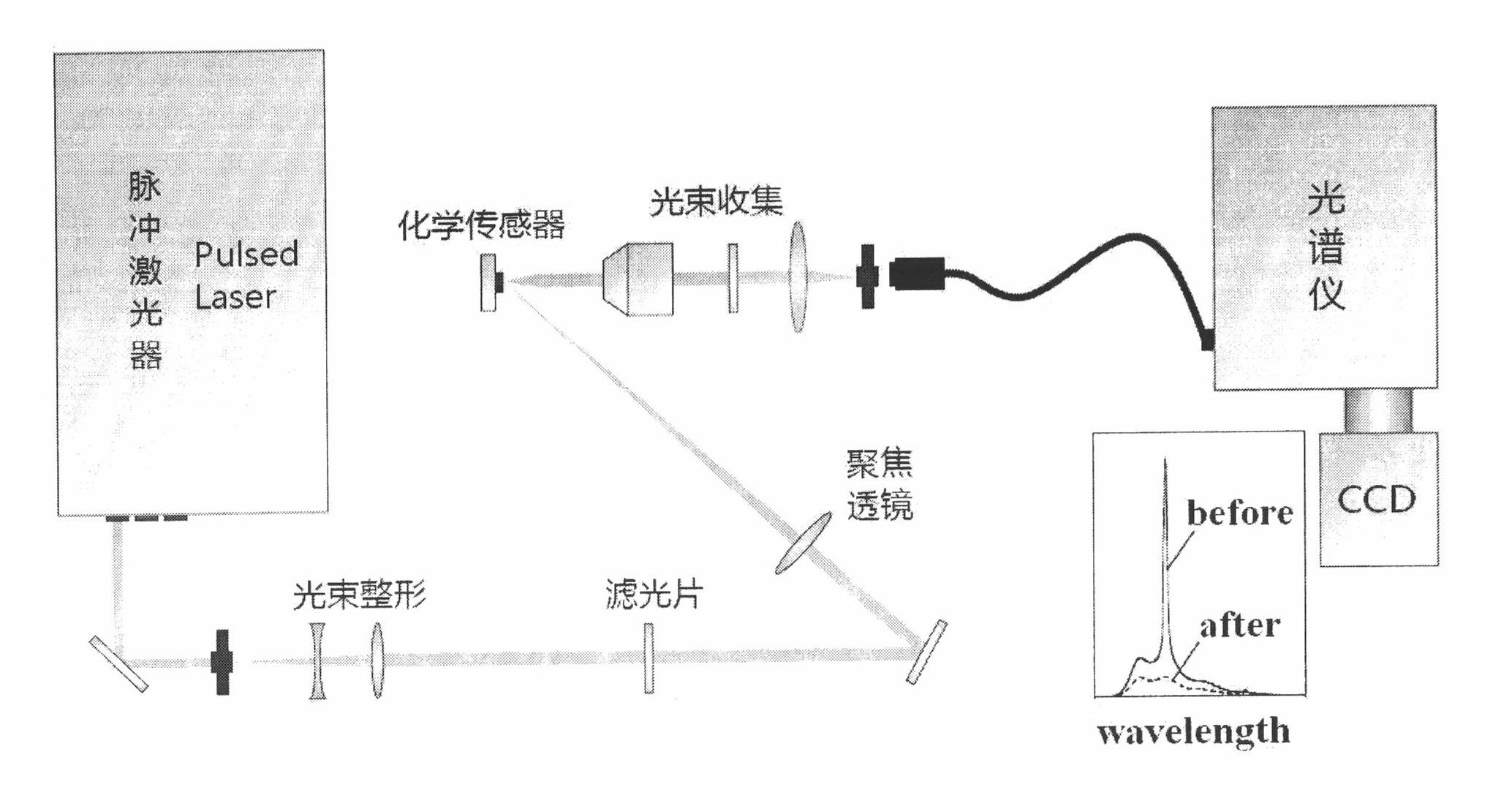

Method used

Image

Examples

Embodiment 1

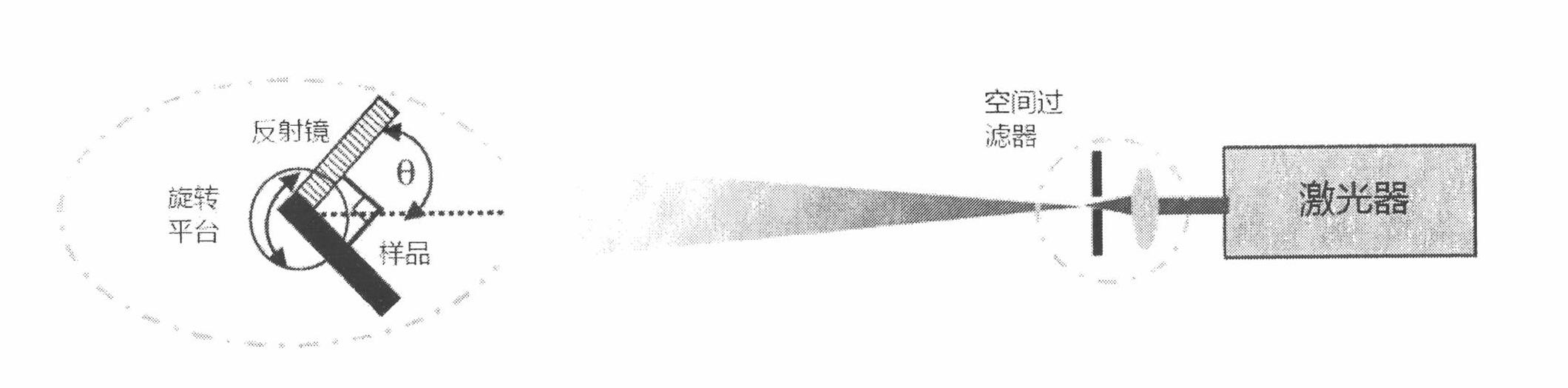

[0030]The process of preparing a distributed Bragg feedback cavity by laser interference lithography: 1. Ultrasonic cleaning of the quartz substrate with concentrated sulfuric acid, acetone, and deionized water for 10 minutes each, and drying; 2. Photoresist 6809 Coat the quartz sheet completely, let it stand for 20 minutes, and throw the glue at 2000 rpm for 30 seconds; 3. Bake the polished quartz sheet at 65°C for 3 minutes, at 95°C for 5 minutes, and then at 0.5°C Cooling at the speed of / min; 4. In the laser interference exposure device, such as figure 2 As shown, at an incident angle of 23°, at 210mJ / cm 2 5. Bake the exposed sample for 2 minutes at 65°C and 7 minutes at 95°C; 5. Put the sample in the developer solution for 6 minutes; 6. Rinse with deionized water 7. Bake the sample at 200°C for 30 minutes; 8. Transfer the periodic grating pattern formed on the photoresist to the quartz plate with glass etching solution for 5 minutes. Finally, a distributed Bragg feedba...

Embodiment 2

[0032] The process of preparing the planar optical waveguide resonant cavity by the film-forming method of throwing glue: 1. Weigh a certain amount of poly-9,9-dioctylfluorene (PFO) and porphyrin metal complex (TPP or MTPP), and prepare 5mL of toluene solution, the concentration ratio of the two is 300:1, and the PFO concentration is 8mg / mL; 2. Throw the mixed solution on a quartz plate by throwing gel film-forming method at a speed of 1500 rpm for 30 seconds, and then place it in a vacuum for drying . It has been determined that the thickness of the film on the quartz plate is about 150nm, and its refractive index (about 1.7) is greater than that of the quartz plate (about 1.5) and air (about 1), thus forming a three-layer planar optical waveguide resonant cavity.

Embodiment 3

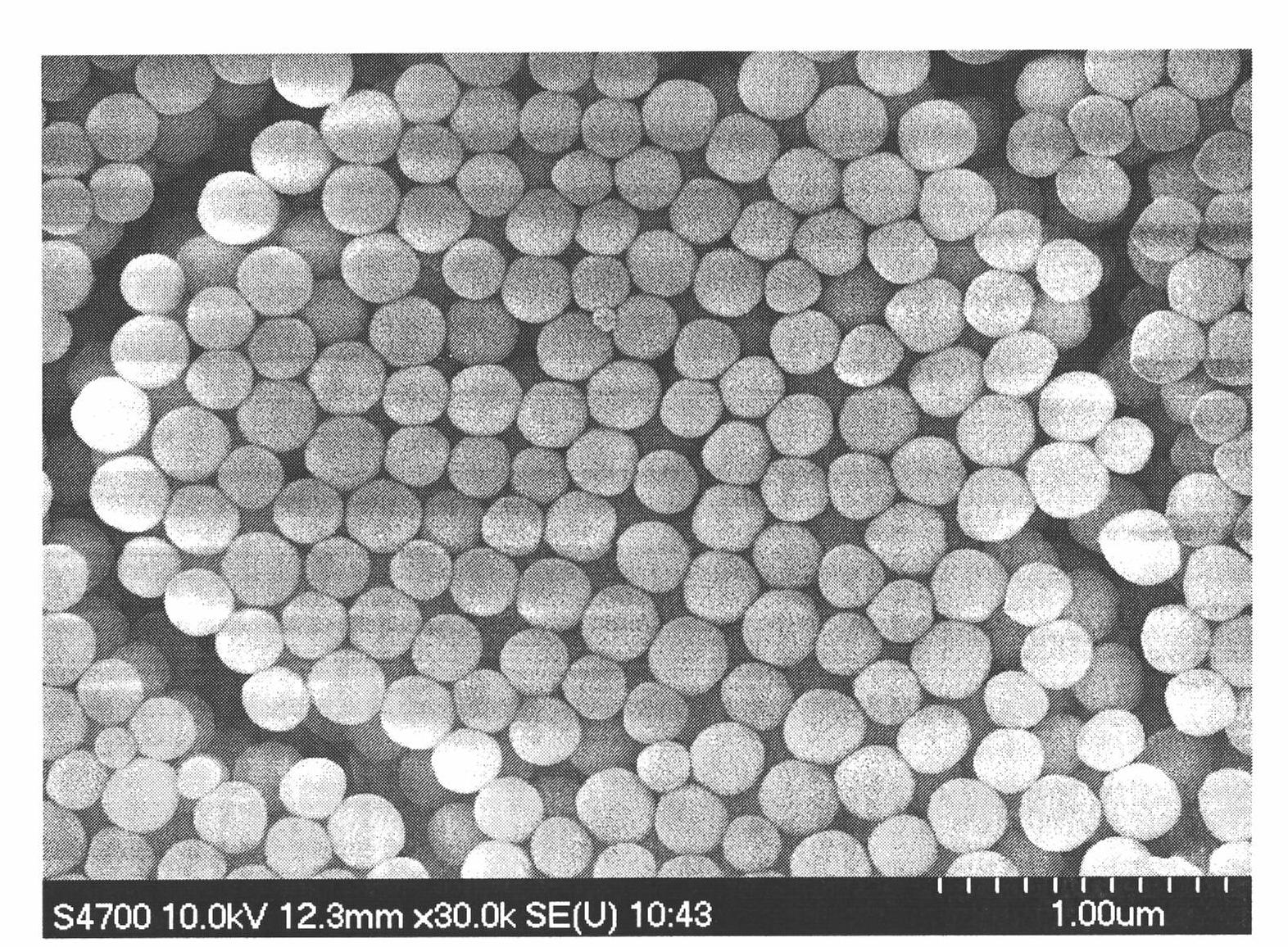

[0034] The process of preparing photonic crystal microcavity by vertical deposition method: 1. Mix 2.08g tetraethyl orthosilicate (TEOS) with 50mL absolute ethanol in a conical flask; 2. Separately mix 3.00g deionized water, 3.85mL concentrated Mix ammonia water and 40mL absolute ethanol in another Erlenmeyer flask; 3. Mix the two liquids under magnetic stirring at room temperature, and continue to stir for 20h to obtain 200nm SiO 2 Particle dispersion; 4. Insert the cleaned quartz slice vertically into 8mL SiO2 2 In a 10mL container of particle dispersion, at room temperature, with the volatilization of ethanol and water in the dispersion, SiO 2 The particles focus on the surface of the quartz sheet, and under the action of capillary force, a three-dimensional ordered SiO is formed on the substrate. 2 colloidal crystals. After the ethanol and water were completely volatilized, the substrate was taken out, and the crystal morphology was observed with a scanning electron micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com