Method for pretreating atrazine production wastewater

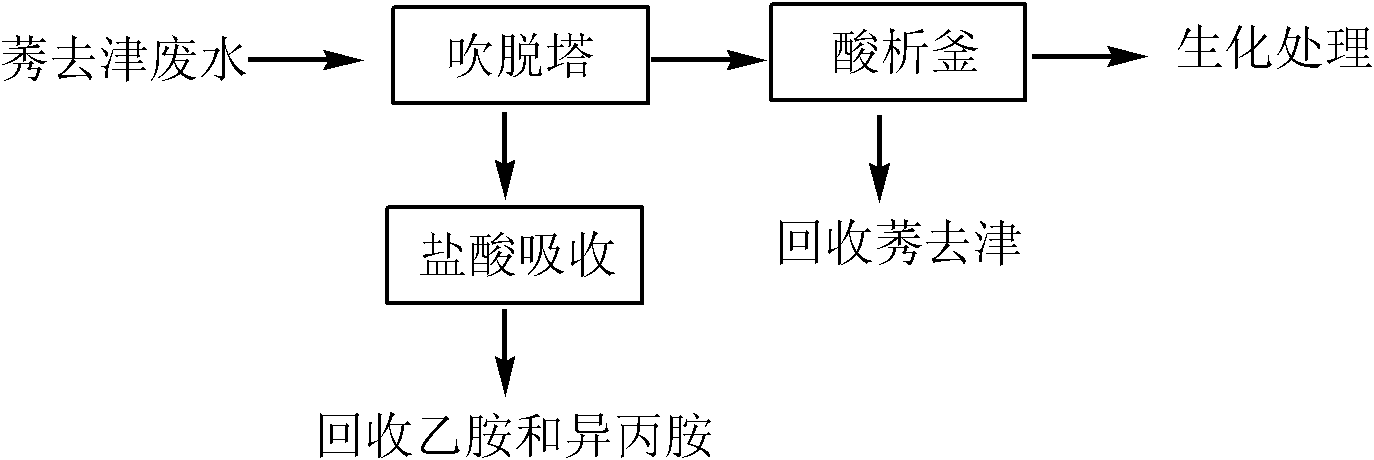

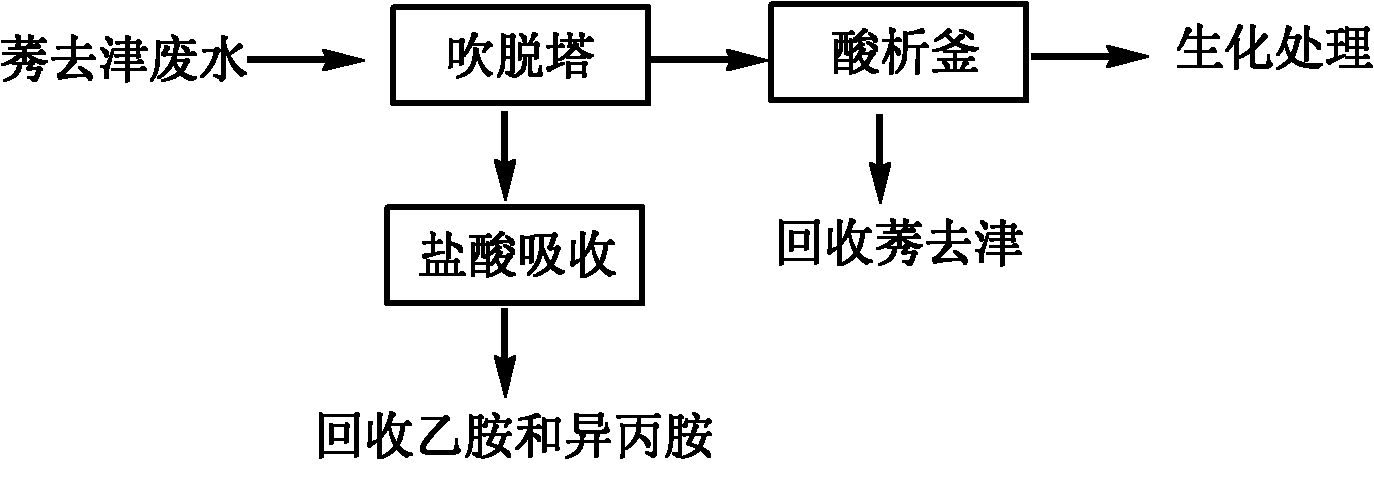

A technology for the production of wastewater and atrazine, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the problems of incomplete regeneration of activated carbon and failure to solve the problems of raw material recovery in wastewater , to achieve the effects of improving biochemical feasibility, reducing subsequent biochemical load, and good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The 8m produced during the preparation of atrazine 3 Wastewater according to 2.7m 3 / h speed is continuously transported from the top of the tower to the air stripping tower in the form of spraying, compressed air is blown in from the bottom of the tower, the gas-liquid ratio is 1000, continuous stripping for 3 hours, and the tail gas is absorbed by 60L hydrochloric acid (concentration 30%, the same below) , to obtain a mixture of ethylamine and isopropylamine hydrochloride, which contained 16.4kg of ethylamine and 21.5kg of isopropylamine, respectively, and was sent to the atrazine production section as a reaction raw material. After stripping, the ammonia nitrogen in the tower bottom wastewater dropped from 1293mg / L to 30mg / L, the COD dropped from 3272mg / L to 1200mg / L, and the pH value was 8.5.

[0022] After blowing off, the waste water is sent to 10m 3 In the enamel kettle, add 16.0L concentrated sulfuric acid to adjust the pH value to 1.0, stir and react at room ...

Embodiment 2

[0024] The 8m produced during the preparation of atrazine 3 Wastewater according to 1.8m 3 / h speed is continuously transported from the top of the tower to the air stripping tower in the form of spraying, compressed air is blown in from the bottom of the tower, the gas-liquid ratio is 800, continuous stripping is carried out for 4.5 hours, and the tail gas is absorbed by 60L hydrochloric acid to obtain ethylamine and isopropylamine The hydrochloride mixture was determined to contain 16.5kg of ethylamine and 21.6kg of isopropylamine respectively, and was sent to the atrazine production section as a reaction raw material. After stripping, the ammonia nitrogen in the tower bottom wastewater dropped from 1293mg / L to 25mg / L, the COD dropped from 3272mg / L to 1150mg / L, and the pH value was 8.0.

[0025] After blowing off, the waste water is sent to 10m 3 In the enamel kettle, add 8.0L concentrated sulfuric acid to adjust the pH value to 2.0. After stirring and reacting at room tem...

Embodiment 3

[0027] The 8m produced during the preparation of atrazine 3 Wastewater according to 1.3m 3 / h speed is continuously transported from the top of the tower to the air stripping tower in the form of spraying, compressed air is blown in from the bottom of the tower, the gas-liquid ratio is 800, and the stripping is continued for 6 hours. The tail gas is absorbed by 60L hydrochloric acid aqueous solution to obtain ethylamine and isopropylamine The hydrochloride mixture was determined to contain 16.5kg of ethylamine and 21.6kg of isopropylamine respectively, and was sent to the atrazine production section as a reaction raw material. After stripping, the ammonia nitrogen in the tower bottom wastewater dropped from 1293mg / L to 20mg / L, the COD dropped from 3272mg / L to 1124mg / L, and the pH value was 7.5.

[0028] After blowing off, the waste water is sent to 10m 3 Add 32L of concentrated hydrochloric acid to the enamel kettle to adjust the pH value to 1.0. After stirring and reacting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com