Polyitaconic acid and preparation method thereof

A technology of polyitaconic acid and itaconic acid, applied in chemical instruments and methods, water/sludge/sewage treatment, descaling and water softening, etc. Less, no three wastes discharge, high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

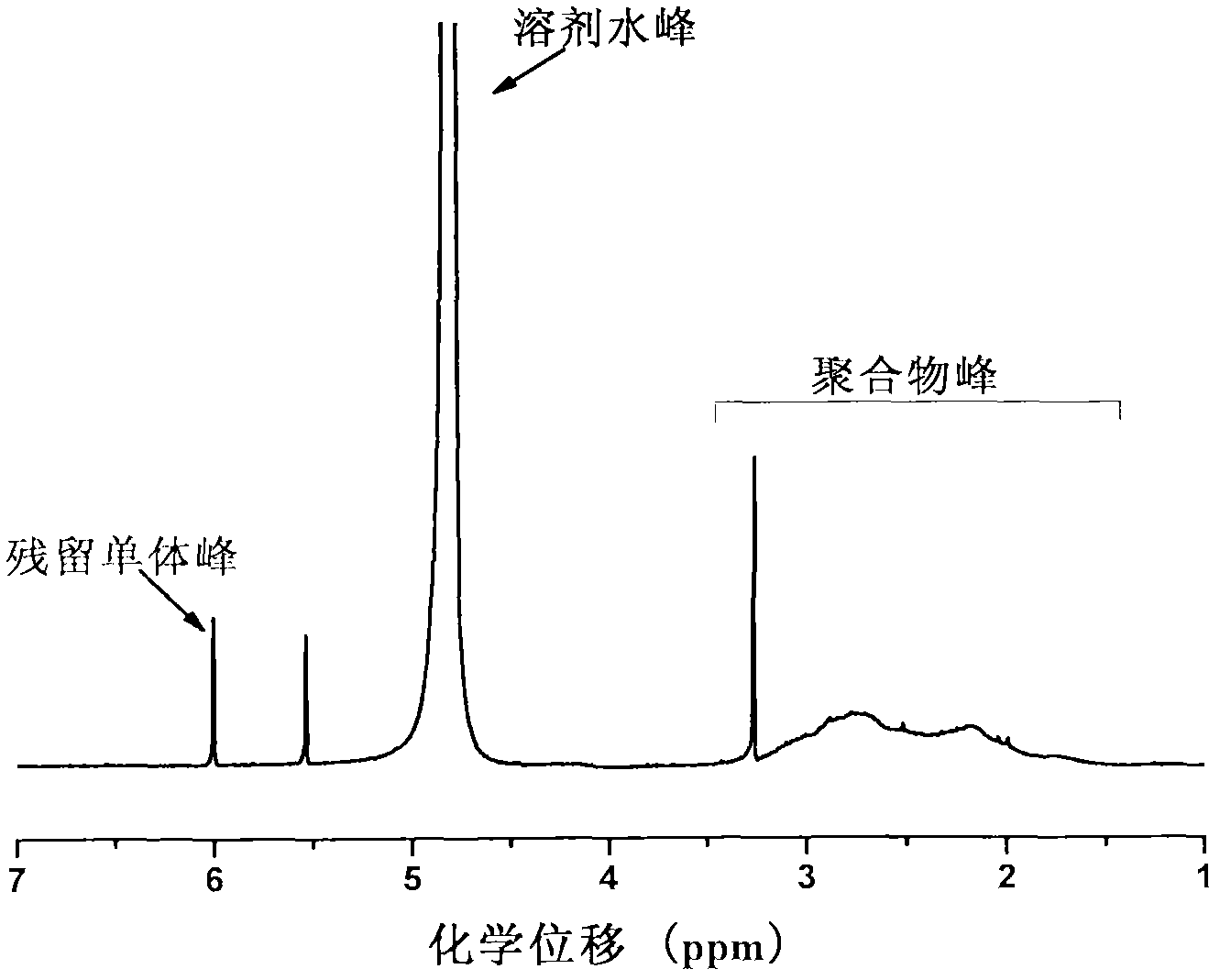

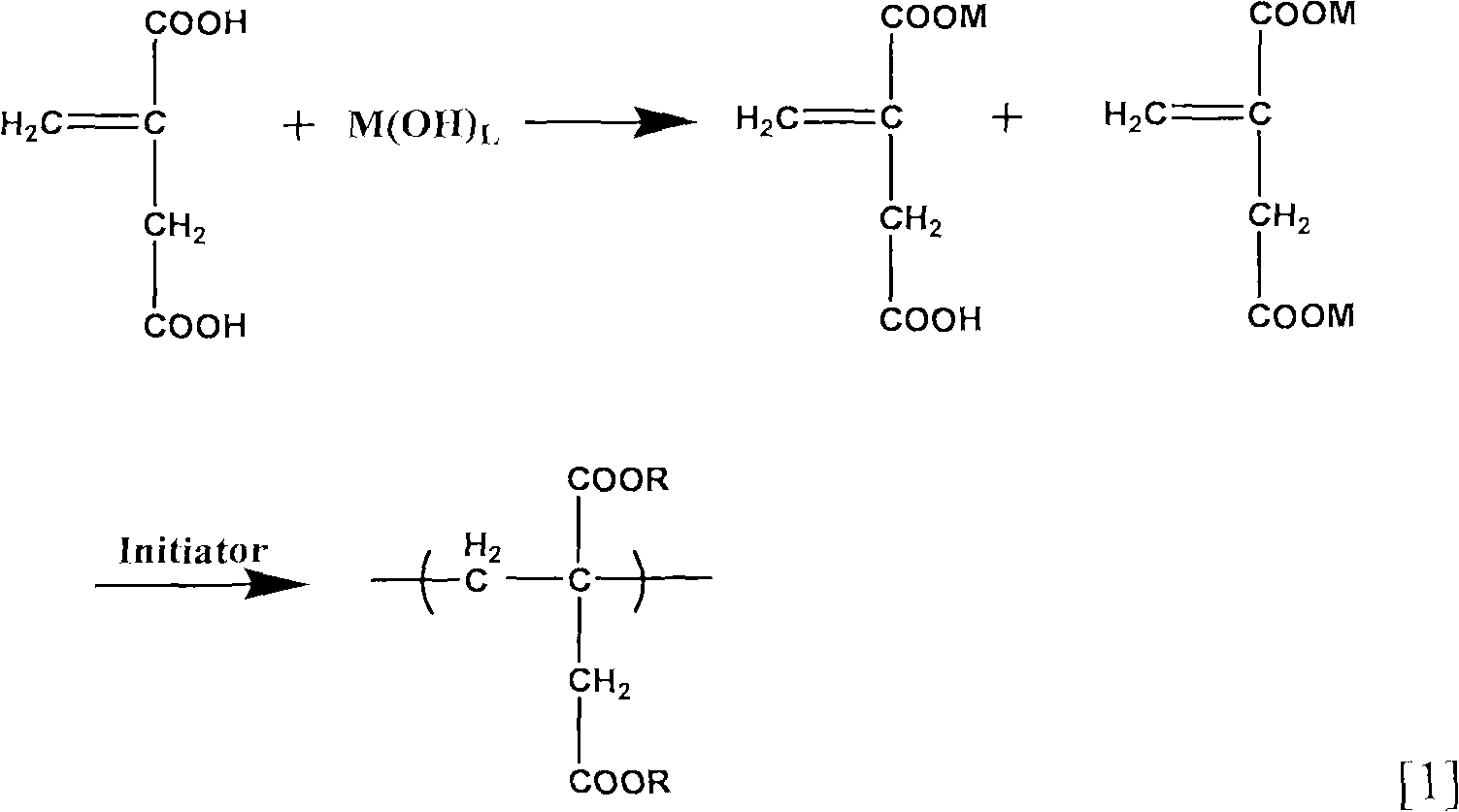

[0025] Specifically, the preparation method of the polyitaconic acid of the present invention is characterized in that the following steps are adopted: 60% to 150% of water (based on the quality of itaconic acid), preferably 60% to 100%, is added to the reaction In the device, heat to a certain temperature (between 60°C and 120°C), and slowly add partly neutralized itaconic acid monomer solution and initiator solution to the reaction device; or, slowly add the initiator solution dropwise to Polymerization was carried out in a partially neutralized itaconic acid monomer solution. Based on the amount of the carboxyl group in the itaconic acid, the degree of neutralization of the carboxyl group in the itaconic acid monomer is 25% to 100%. Wherein, based on the amount of the carboxyl group in itaconic acid, when itaconic acid is partially neutralized, the amount of alkali added is 25% to 100% of the carboxyl group, and the degree of neutralization of the itaconic acid monomer is 2...

Embodiment 1

[0044] Add 30 g of water into a four-necked reaction flask equipped with a thermometer, two dropping funnels, a reflux condenser and a stirrer, and heat the flask to 70°C. To prepare a partially neutralized itaconic acid monomer solution, weigh 45.5 g of itaconic acid monomer, dissolve it in 30 g of water, and slowly add a certain mass (as shown in Table 1) of a 50% sodium hydroxide solution dropwise. An initiator solution was prepared containing 2.5 g ammonium persulfate and 10 g deionized water. Simultaneously, the monomer and the initiator solution were slowly added dropwise, and the dropwise addition was completed in 1 hour. At the same time, the temperature of the reaction flask was kept at 70°C. After the dropwise addition was completed, the reaction was incubated for 0.5h. Cool to room temperature and discharge to obtain polyitaconic acid. The appearance of the product is light yellow or dark red solution.

[0045] Table 1: The effect of the amount of sodium hydroxid...

Embodiment 2

[0050] Add 30 g of water into a four-necked reaction flask equipped with a thermometer, two dropping funnels, a reflux condenser and a stirrer, and heat the flask to 80°C. To prepare a partially neutralized itaconic acid monomer solution, weigh 45.5 g of itaconic acid monomer, dissolve it in 30 g of water, then slowly add 42.0 g of 50% sodium hydroxide solution dropwise, and the degree of neutralization is 75%. Then prepare an initiator solution containing a certain amount of ammonium persulfate and 10 g of deionized water, and the amount of the initiator added is shown in Table 2. Simultaneously, the monomer and the initiator solution were slowly added dropwise, and the dropwise addition was completed in 1 hour. At the same time, the temperature of the reaction flask was kept at 80°C. After the dropwise addition was completed, the reaction was incubated for 0.5h. Cool to room temperature and discharge to obtain polyitaconic acid. The appearance of the product is light yello...

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com