Method for preparing copper indium gallium selenide (CIGS) solar battery buffer layer

A technology of solar cells and copper indium gallium selenide, which is applied in the field of solar cells, can solve problems such as low cost, slow natural growth, and complicated process, and achieve the effects of improving production efficiency, ensuring density, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

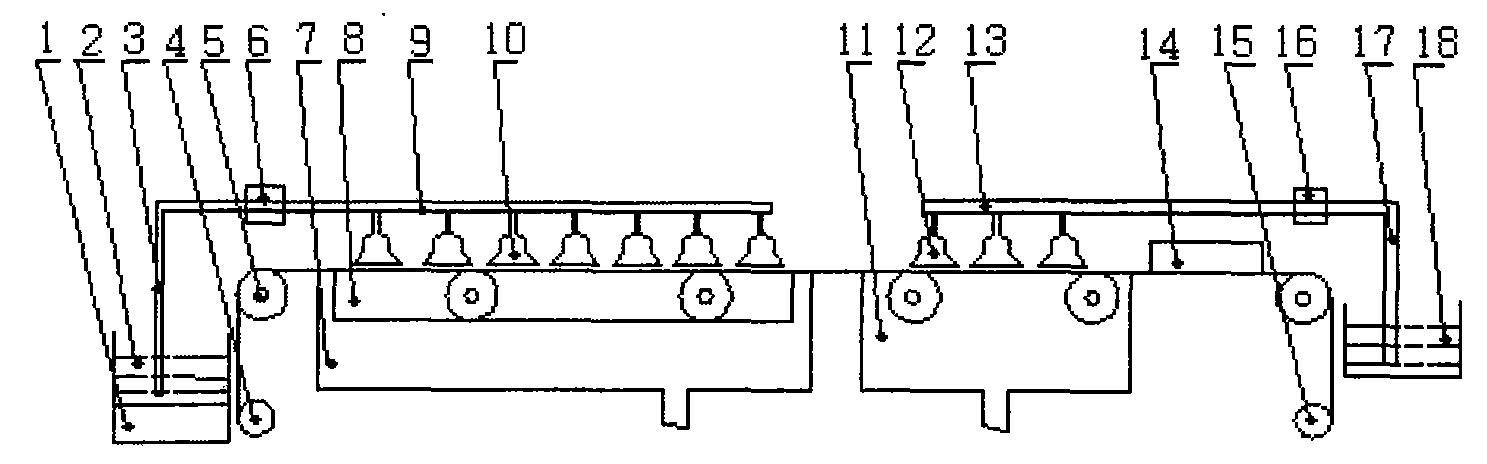

[0023] like figure 1 As shown in the figure, a plating solution is sprayed on the substrate, and a CdS film is formed on the substrate as a buffer layer of the solar cell, and the preparation steps are:

[0024] (1) Configure plating solution: place the mixed solution of 0.005M cadmium acetate, thiourea with 5 times the concentration of cadmium acetate, 0.005M ammonium salt, and 0.005M ammonia water in the plating solution container 2 and stir as a plating solution, then connect to The electric heating plate is used as the plating solution heater 1 to heat the plating solution, and the thermocouple unit (not marked in the figure) controls the plating solution temperature to be 60°C;

[0025] (2) Substrate selection: choose the coiled copper foil as the substrate and install it on the unwinding rack 4, the substrate is laid flat on the conveyor belt 5 of the production line, the end of the substrate is wound on the winding rack 15, and the electric heating plate is turned on. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com