Method for preparing polyfluortetraethylene dispersion resin

A polytetrafluoroethylene and dispersion resin technology, which is applied in the field of preparation of polytetrafluoroethylene dispersion resin for extruded pipes, can solve the problems affecting product performance and appearance, unstable end group form, unstable polymerization system, etc., and save manpower and hydropower resources, good push extrusion performance, small molecular weight dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Clean the 50L stainless steel reactor, add 32L of deionized water, 300g of solid paraffin, and 100g of perfluorooctanoic acid ammonium. After sealing the reactor, evacuate it and replace it with nitrogen. If the oxygen content is ≤50ppm, it is qualified. Evacuate, replace it with TFE, and analyze the oxygen content. Content ≤ 30ppm is qualified;

[0027] 2. Then raise the temperature of the reaction kettle to 70±1°C, put in the mixed gas-phase monomer TFE and HFP until the pressure inside the kettle is 2.5MPa, then add 0.15g of ammonium persulfate and 5g of succinic acid peroxide (dissolved in deionized water) ;

[0028] 3. After the reaction starts, continuously add TFE to maintain the pressure in the kettle to be 2.5MPa; when the polymerization reaction is carried out until TFE consumes 20%, add 5g of succinic acid peroxide (dissolved in deionized water) to continue the reaction; Carry out to TFE consumption 40%, add 5g succinic acid peroxide (dissolved in deioniz...

Embodiment 2

[0033] Prepare polytetrafluoroethylene dispersion resin according to the formula of embodiment 1 and preparation steps, difference is: add 0.1g ammonium persulfate, 5g succinic acid peroxide before reaction starts; Add 4g peroxysuccinic acid for the first time; add 6g peroxysuccinic acid for the second time when the polymerization reaction is carried out to TFE consumption 60%.

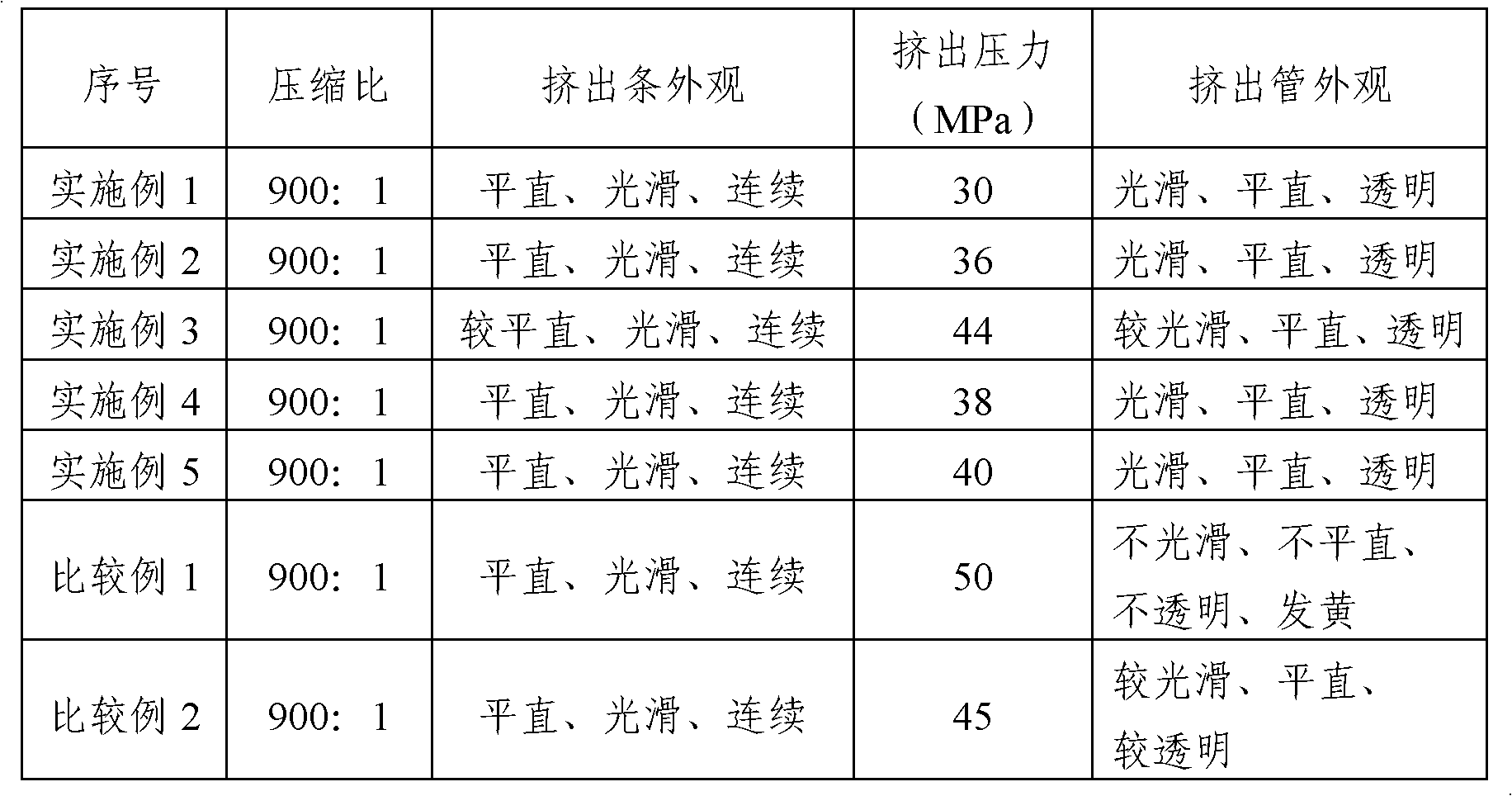

[0034] The paste extrusion performance of the prepared polytetrafluoroethylene resin was measured, and the results are shown in Table 1.

Embodiment 3

[0036] According to the formula and reaction conditions of Example 2, the difference is: add 0.2g ammonium persulfate and 5g succinic acid peroxide before the reaction begins; add 3g butyl peroxide for the first time when the reaction is carried out until TFE consumes 30% Diacid, add 2g peroxysuccinic acid for the second time after monomer recovery.

[0037] The paste extrusion performance of the prepared polytetrafluoroethylene resin was measured, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com