Method for preparing ternary-component AlxGaI-xN nanocone

A technology of alxga1-xn and nano-cone, which is applied in chemical instruments and methods, gaseous chemical plating, crystal growth, etc., can solve the problem that GaN and AlN growth conditions are difficult to match, AlGaN products spontaneously phase separate, and single-phase AlGaN nanometers cannot be obtained. Structure and other issues, to achieve the effect suitable for large-scale production, uniform size, large aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 anhydrous GaCl 3 and anhydrous AlCl 3 Preparation of single-phase Al for precursor deposition x Ga 1-x N nanocone arrays.

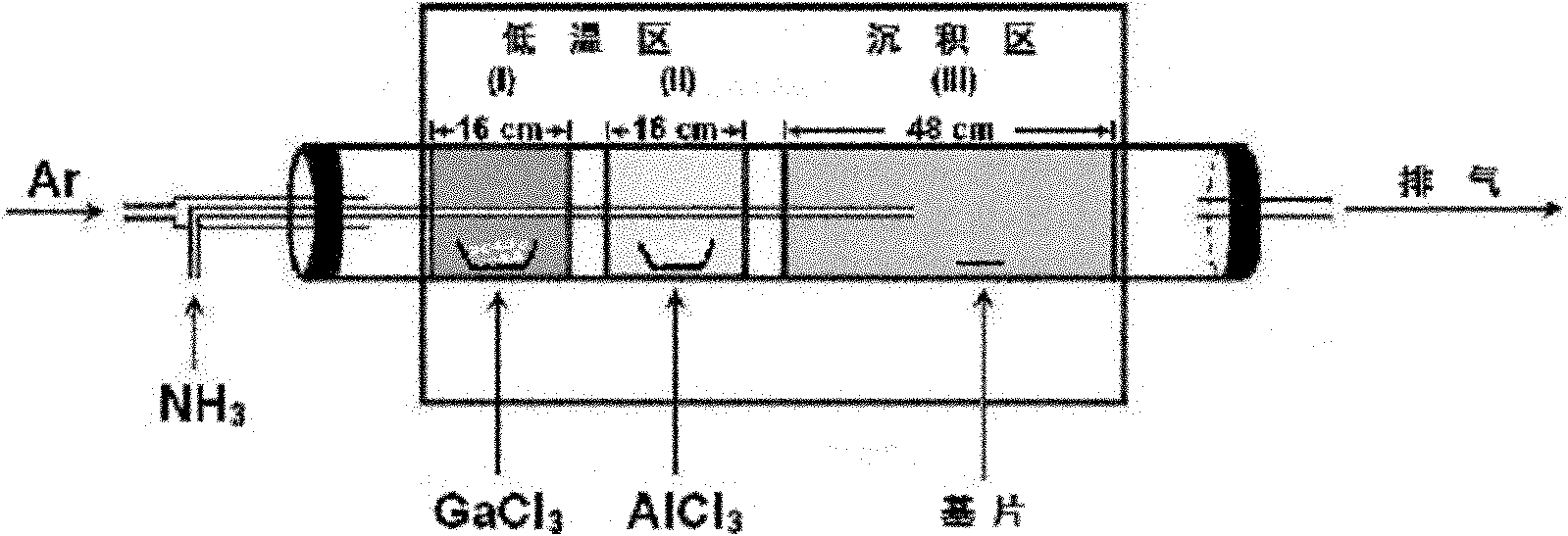

[0035] 0.4 g anhydrous GaCl 3 and anhydrous AlCl 3 respectively placed in the three-section temperature zone tube furnace (as attached figure 1 ) of the low temperature zones (I) and (II), the substrate is placed in the deposition zone (III). The system was repeatedly evacuated by a mechanical pump and filled with Ar gas three times before heating to remove oxygen and water in the reaction system. Under the protection of Ar gas, the temperature of the deposition zone was raised to 700°C (the heating rate was 10°C / min), and the temperature of the low-temperature zone (I) and (II) was rapidly (about 10 minutes) raised to 80°C (GaCl 3 evaporation temperature) and 140°C (AlCl 3 evaporation temperature). When the temperature rises to the specified value, increase the Ar gas flow to 300 mL / min, and feed NH 3 20 mL / min, GaCl 3 a...

Embodiment 2

[0036] Example 2 Single-phase Al with tunable composition x Ga 1-x Fabrication of N nanocone arrays.

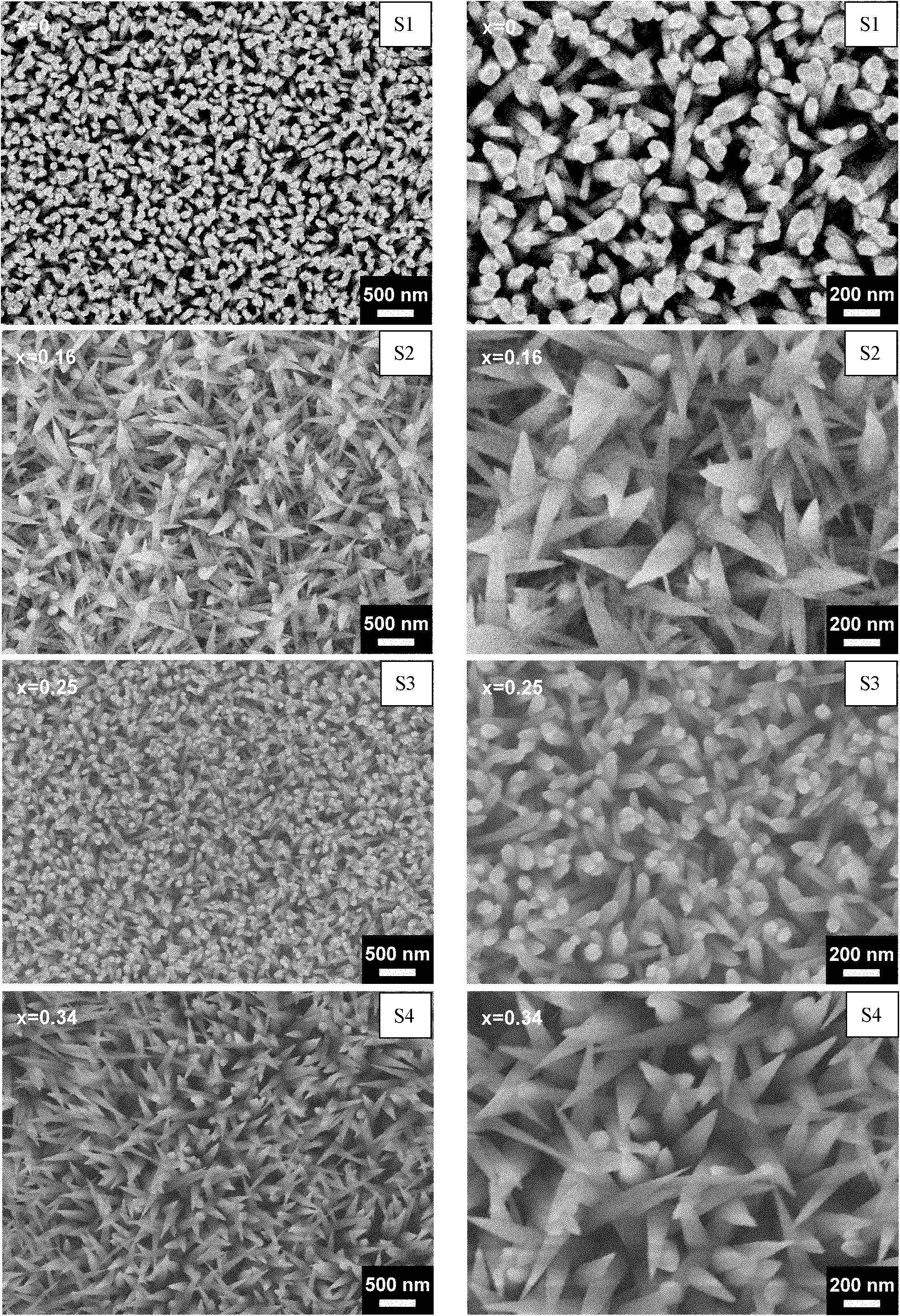

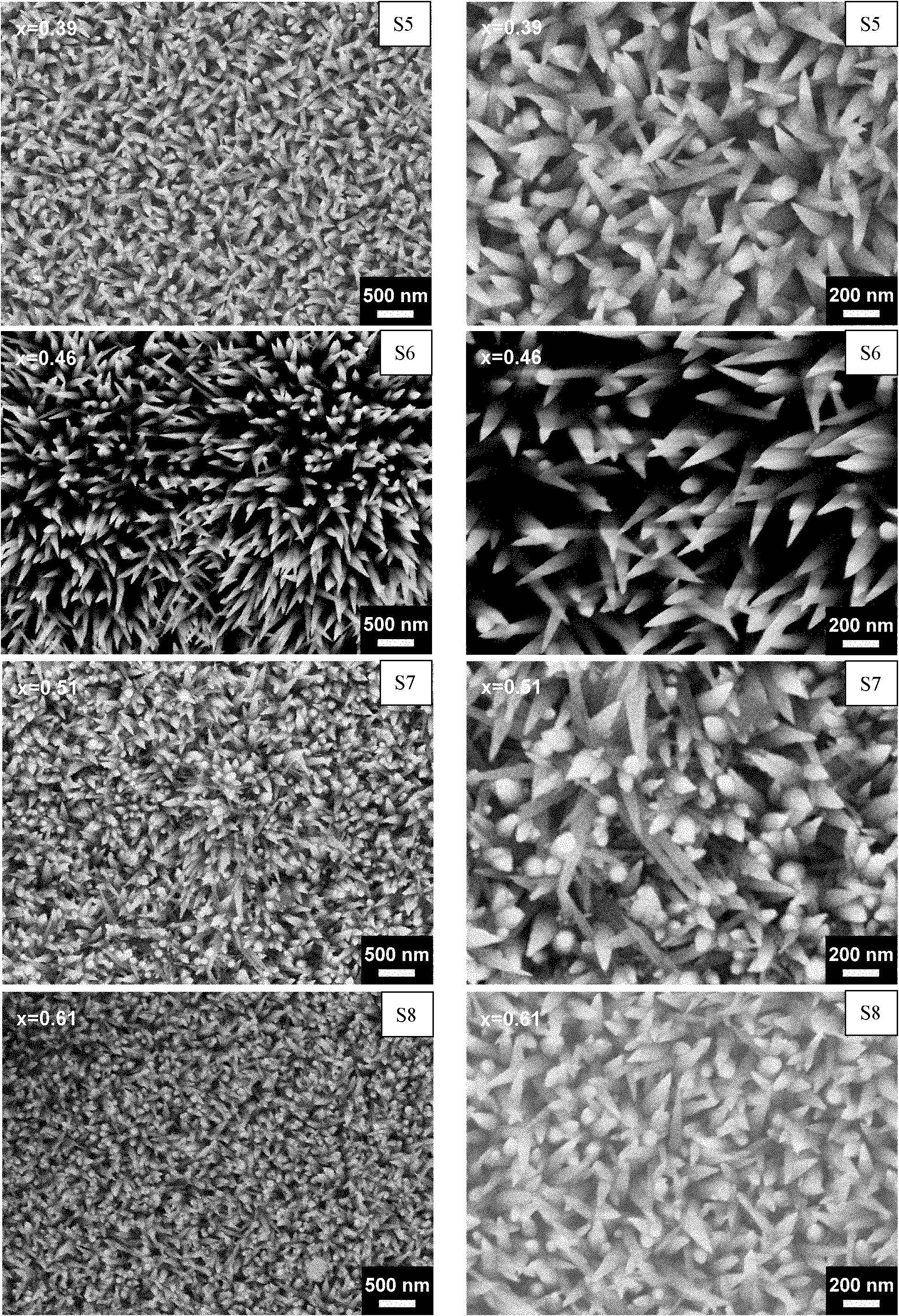

[0037] Similar to the operation steps in Example 1, this example is by changing the precursor GaCl 3 and AlCl 3 The evaporation temperature of GaCl can be tuned 3 and AlCl 3 Vapor partial pressure of , thus achieving single-phase Al x Ga 1-x Fabrication of N nanocone arrays and their composition modulation. In order to obtain single-phase Al x Ga 1-x N nanocones, GaCl 3 and AlCl 3 The vapor partial pressures must match each other. The optimized reaction condition of the present invention is: GaCl 3 and AlCl 3 The evaporation temperatures are 70-90°C and 130-150°C, respectively. In this temperature range, according to AlCl 3 In order of gradual increase of the vapor partial pressure, the system modulates the GaCl 3 and AlCl 3 The vapor partial pressure of the series Al can be obtained x Ga 1-x N samples. The characterization results show that the obtain...

Embodiment 3

[0040] Example 3 anhydrous GaCl 3 GaN nanowire arrays were fabricated for precursor deposition.

[0041] Anhydrous GaCl 3 The powder is placed in a three-stage temperature zone tube furnace (as attached figure 1 ), the substrate is placed in the deposition area. The system was repeatedly evacuated by a mechanical pump and filled with Ar gas three times before heating to remove oxygen and water in the reaction system. Under the protection of Ar gas, the temperature of the deposition area was raised to 700°C (the heating rate was 10°C / min), and at the same time, the temperature of the low temperature area was rapidly (about 10 minutes) raised to 80°C. When the temperature rises to the specified value, increase the Ar gas flow to 300 mL / min, and feed NH 3 20 mL / min, GaCl 3 Vapor is carried by Ar gas to the deposition area and NH 3 Gas reaction, deposition on the substrate to obtain GaN products. The reaction time is 2-4 hours. After the reaction, the system is cooled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com