Method and device for preparing high-boiling-point silicone oil

A high-boiling silicone oil, high-boiling technology, applied in the equipment for implementing the method, alcoholysis of chlorosilane to produce alkoxy silicone oil, and alcoholysis of organosilicon high-boiling substance or/and azeotrope to produce high-boiling silicone oil field, can solve the problem. Hydrogen chloride gas is difficult to fully resolve, storage stability is affected, and the amount of neutralizer is large, so as to achieve the effects of controllable molecular weight and viscosity, reduced dosage, and fewer side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

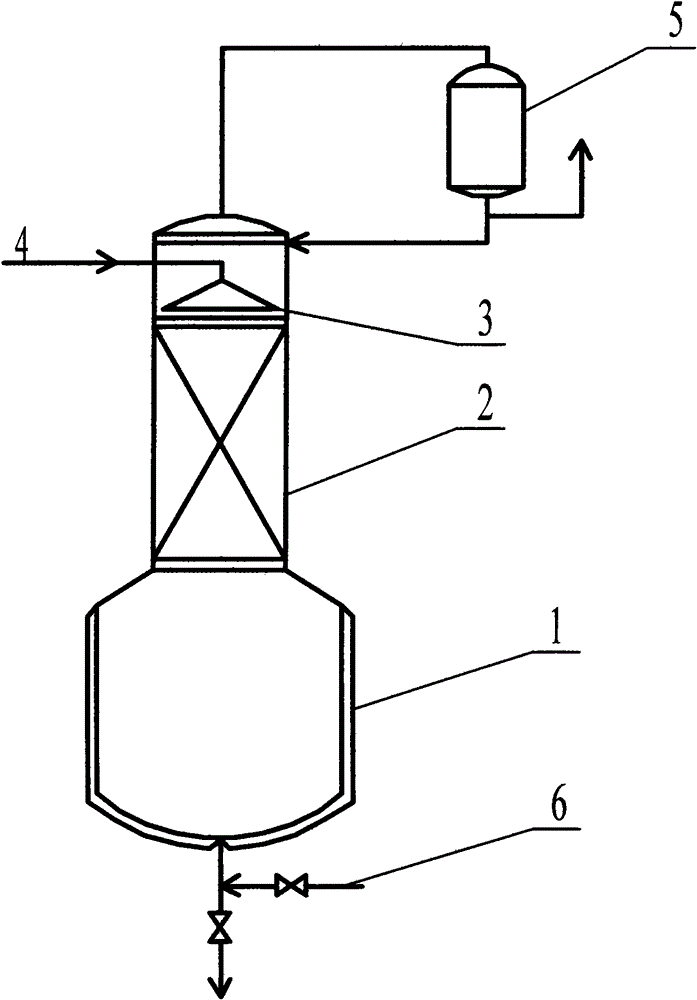

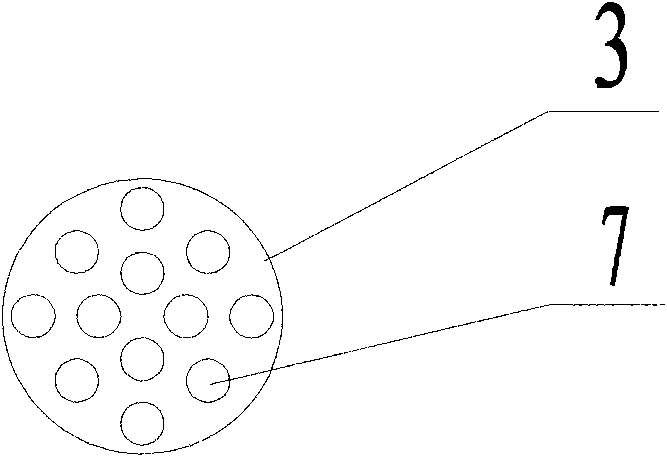

Image

Examples

Embodiment 1

[0040] Take 100 parts of organic silicon high boilers and 40 parts of methanol. The temperature of the reactor at the bottom of the tower is pre-heated to 70°C, and from the bottom of the reactor, the organosilicon high-boiling substance and methanol are pumped into the top of the tower with a metering pump, and the materials enter the bottom of the kettle through the top of the tower through the filler in the tower. After the addition is complete, the temperature is raised to 100°C, and the reflux deacidification is continued for 3 hours. After deacidification is completed, the temperature is lowered to 40°C, and the materials are pumped into the neutralization kettle. Add 25 parts of urea, 2 parts of zinc oxide as a flux, 15 parts of ammonium bicarbonate as a neutralizer, and neutralize the dissolved hydrogen chloride. After the addition, continue to stir for 30 minutes and let stand for layering. The lower eutectic is separated into the lime pond through the neutralization ...

Embodiment 2

[0042] Take 100 parts of organic silicon high boilers and 45 parts of methanol. The temperature of the kettle is pre-heated to 50°C, the nitrogen valve is opened, and the high-boiling organic silicon and methanol are driven into the tower at a weight ratio of 2.2 / 1 with a metering pump. After the addition is completed, the temperature is raised to 60°C, and nitrogen is continued to flow back and deacidify for 2 hours. After deacidification, the temperature is lowered to 40°C, the nitrogen gas is stopped, and the materials are pumped into the neutralization kettle. Add 40 parts of urea, 6 parts of flux (zinc oxide and sodium hydroxide at a ratio of 1 / 0.5), 25 parts of neutralizer (a ratio of ammonium bicarbonate and ethylenediamine at 1 / 0.6), and continue after adding Stir for 30 minutes and let stand for layering. The lower layer material is put into the lime pond to continue neutralization to neutrality, and 3 parts of the neutralizer is added to the upper layer material, an...

Embodiment 3

[0044] Take 100 parts of organic silicon high boilers and 50 parts of methanol. The temperature of the kettle is pre-heated to 80°C, the nitrogen valve is opened, and the high-boiling organic silicon and methanol are pumped into the tower with a metering pump. After the addition is complete, the temperature is raised to 120°C, and nitrogen is continued to flow back and deacidify for 5 hours. After deacidification, the temperature is lowered to 40°C, the nitrogen gas is stopped, and the materials are pumped into the neutralization kettle. Add 10 parts of urea, 0.5 parts of flux (zinc oxide and sodium carbonate at a ratio of 1 / 0.2), 8 parts of neutralizer (a ratio of ammonium bicarbonate and triethanolamine at a ratio of 1 / 0.6), and continue to stir after adding 30 For minutes, let stand for layering. The lower layer material is put into the lime pool to continue neutralization to neutrality, 0.5 part of neutralizer is added to the upper layer material, and the high boiling sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com