Hydrotreating catalyst and application thereof

A hydrogenation treatment and catalyst technology, applied in physical/chemical process catalysts, metal/metal oxides/metal hydroxide catalysts, through the hydrogenation of aromatics, etc., can solve aromatics saturation performance and low hydrodesulfurization activity and other problems, to achieve the effect of improving the performance of the catalyst and increasing the activity relative to aromatics saturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of pseudo-boehmite P1 with 1.1≤n≤2.5 includes: contacting an aluminum-containing compound solution with acid or alkali for precipitation reaction, or contacting an organic aluminum-containing compound with water for hydrolysis reaction to obtain hydrated alumina Aging the alumina hydrate obtained above, wherein, the contact of the aluminum-containing compound solution with acid or alkali or the contact of the organic aluminum-containing compound with water and the aging of the alumina hydrate are carried out in the crystal grains The process is carried out in the presence of a growth regulator, which is a substance capable of regulating the growth rate of crystal grains on different crystal planes.

[0031] Although the object of the present invention can be achieved as long as any one of the hydrolysis reaction or the precipitation reaction and the aging process is carried out in the presence of a grain growth regulator, preferably, the hydrolysis...

Embodiment 1

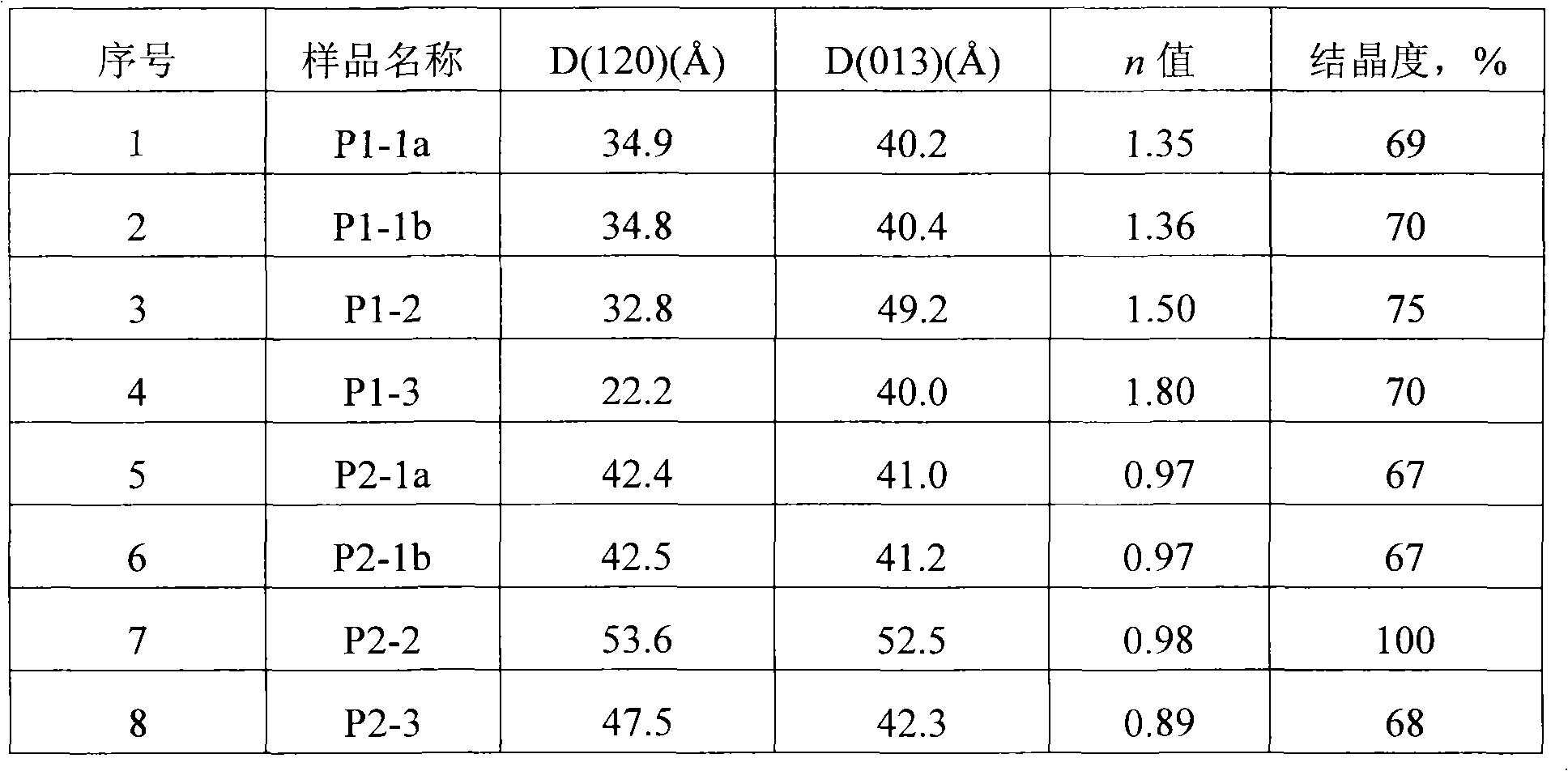

[0108] (1) Compositions and preparations of pseudo-boehmite and silicon-containing compounds suitable for use in the present invention:

[0109] At room temperature, 1600 grams of laboratory-synthesized pseudo-boehmite P1-1a (dry basis 22%) was added to 3000 milliliters of water to make a slurry, and after stirring for 30 minutes, commercial silica gel (Silica Gel 955, U.S. Davison Chemical Company was added) under stirring. Products, containing SiO 2 99.8% by weight) 62 grams, after continuing to stir for 150 minutes, filter, filter cake was dried at 120 ℃ for 10 hours, to obtain the composition ZH-1 of the present invention (dry basis 77%). The composition of ZH-1 was measured by X-ray fluorescence method, and the content of silicon oxide was 15% by weight and the content of aluminum oxide was 85% by weight based on oxide and dry basis.

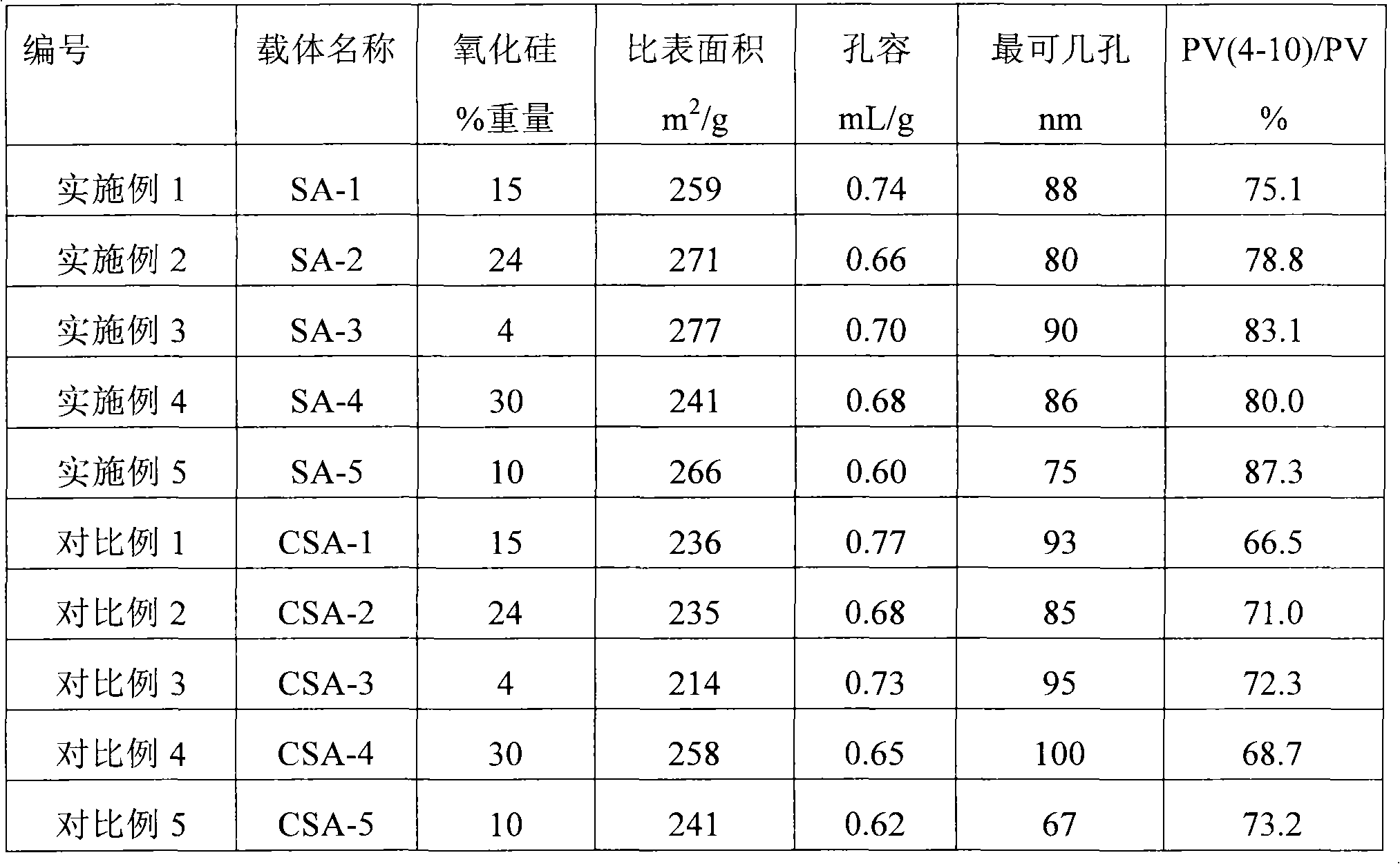

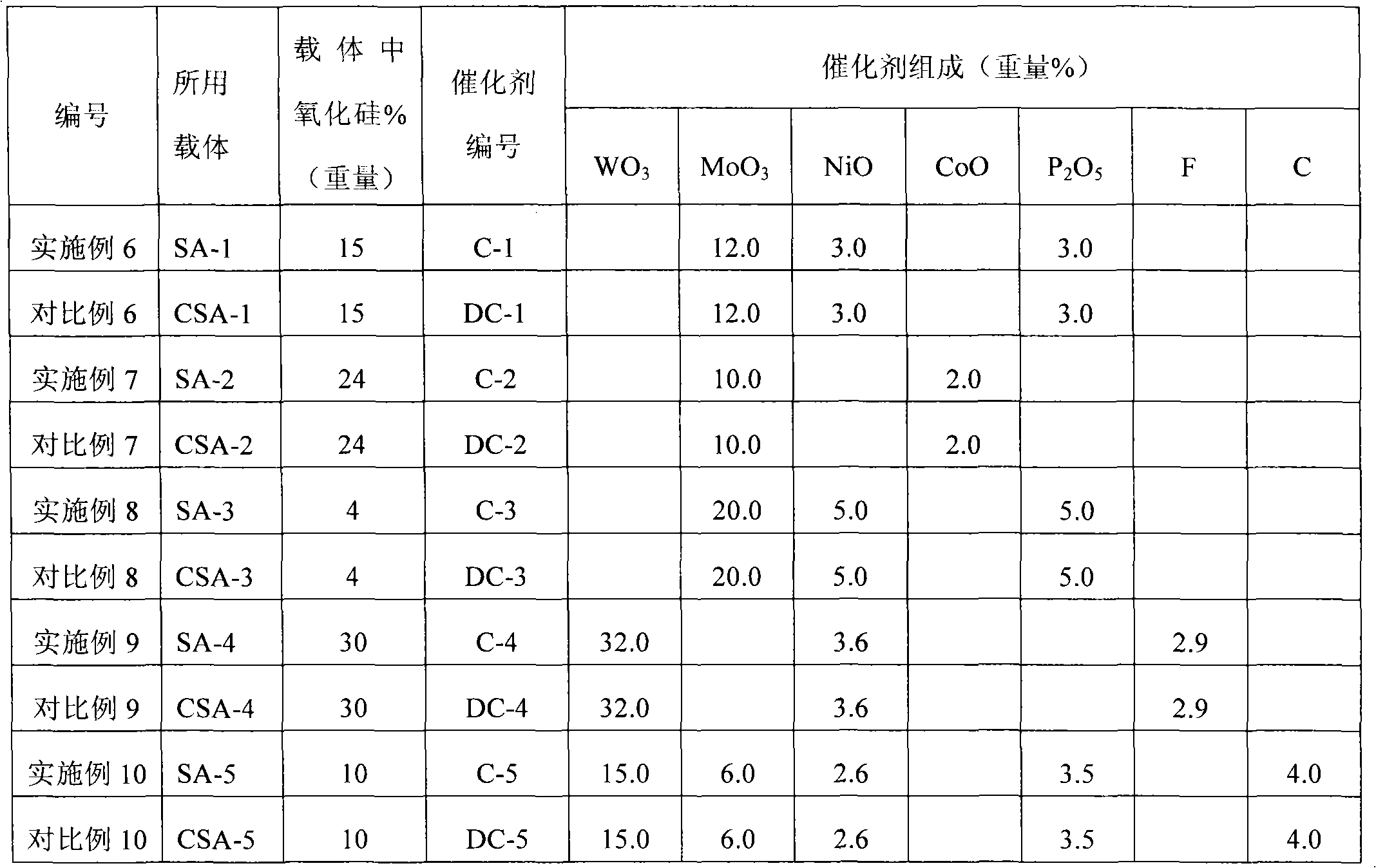

[0110] (2) Silica-alumina carrier suitable for the present invention and preparation thereof:

[0111] 420 grams of ZH-1 are mixed with...

Embodiment 2

[0113] (1) Compositions and preparations of pseudo-boehmite and silicon-containing compounds suitable for use in the present invention:

[0114] Pseudo-boehmite P1-1b (dry basis 70%) and silica sol (containing SiO2) synthesized by 400 grams of laboratories 2 30% by weight (produced by Beijing Feilongma Company) 295 grams and 11 grams of Selina powder mixed, then mixed with 8.2 milliliters of nitric acid (concentration 65-68%, analytically pure, Shantou Xilong Chemical Plant) and 310 milliliters of water, and then The mixture is kneaded continuously on a twin-screw extruder to obtain the composition ZH-2 of the present invention. ZH-2 is a plastic body, the composition of ZH-2 is determined by X-ray fluorescence method, calculated as oxides and based on the total amount of silicon oxide and aluminum oxide in the composition, the silicon oxide content is 24% by weight , with an alumina content of 76% by weight.

[0115] (2) Silica-alumina carrier suitable for the present inve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com