Method for manufacturing silicon nitride heating body

A technology for a silicon nitride heating element and a manufacturing method, which is applied to heating element materials and other directions, can solve the problems of reducing safety and reliability, deteriorating material insulation properties, and large grain boundary stress, and improving reliability and safety. Relieve material stress and reduce the effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

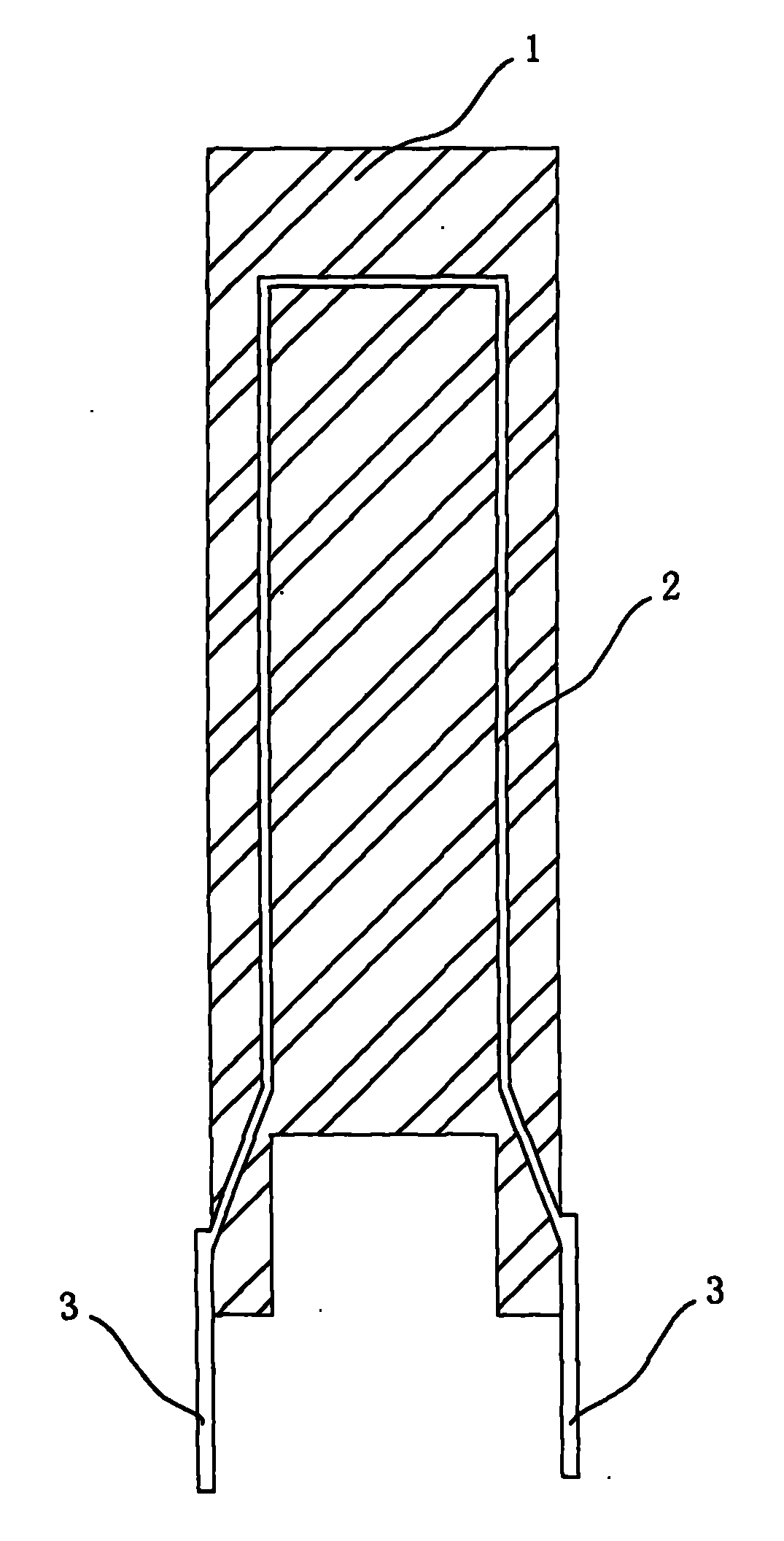

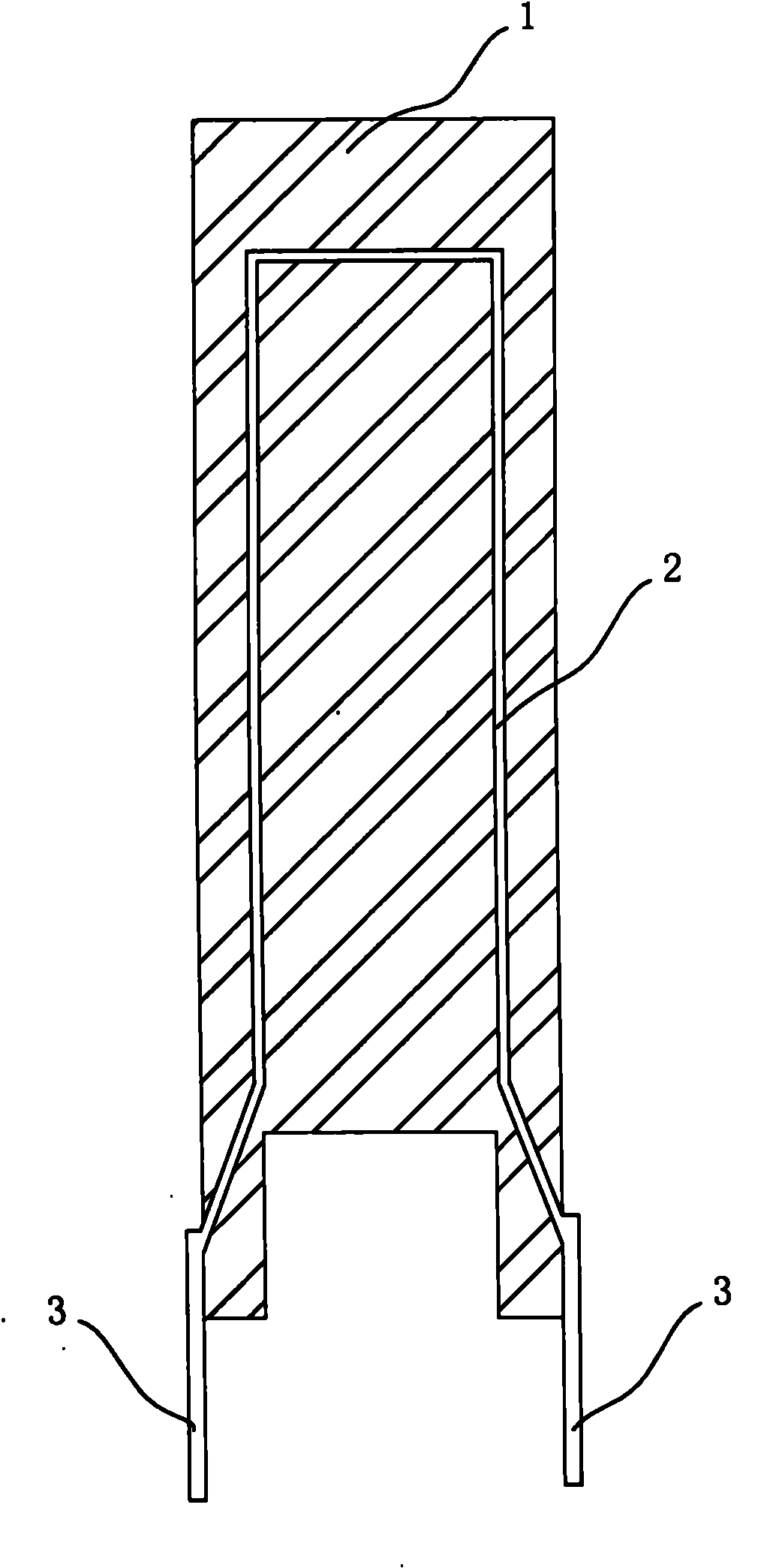

[0021] The silicon nitride heating element in this embodiment is composed of silicon nitride heating element and a high-temperature metal heating wire arranged in the silicon nitride heating element. The metal heating wire is tungsten wire, molybdenum wire or tungsten-molybdenum alloy wire.

[0022] The manufacturing method of the above-mentioned silicon nitride heating element comprises:

[0023] Step 1. Put the silicon nitride powder and the high-temperature liquid phase sintering aid into absolute ethanol in a weight ratio of 0.96:0.04 to 0.80:0.20 and mix (specifically, a ball mill mixer can be used for mixing), and mix for 10-72 hours Afterwards, the formulation is made through spray granulation;

[0024] Step 2, embedding the metal heating wire in the formula and dry-pressing for molding, then further pressing for molding by cold isostatic pressing of 180-220MPa, and holding the pressure for 3-10 minutes to make a green body;

[0025] Step 3, drying after evenly coatin...

Embodiment 2

[0031] On the basis of embodiment 1, the manufacturing method of the silicon nitride heating element of the present embodiment comprises:

[0032] 92wt% silicon nitride powder, 3wt% Al 2 o 3 , 3 wt% Y 2 o 3 , 1wt% of MgO, 1wt% of AlN was added to 99.9% absolute ethanol and mixed uniformly for 72 hours, and then placed in an explosion-proof spray granulation tower for spray granulation to make a formula.

[0033] Pour the formula into the mold, and then embed the metal heating wire in the powder and dry press to form it. The size is 120*20*10. Then the dry-pressed blank is packaged and put into cold isostatic pressing equipment for isostatic pressing. The pressure of isostatic pressing is 200 MPa, and the holding time is 3-10 minutes. Mix high-purity absolute ethanol and boron nitride fine powder to form a thick slurry, apply a layer of uniform boron nitride isolation layer on the surface of the green body by scraping method, and dry it. A layer of boron nitride isolation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com