Cadmium sulfide thin film solar cell and preparation method thereof

A thin-film solar cell and cadmium sulfide technology, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of affecting the performance of the front electrode, incomplete copper diffusion, difficult control, etc., and achieve more stable photoelectric conversion efficiency and high photoelectric conversion Efficiency, the effect of eliminating lattice mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

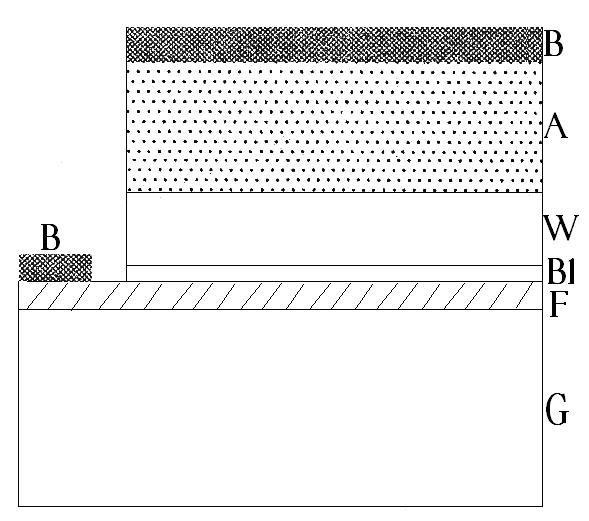

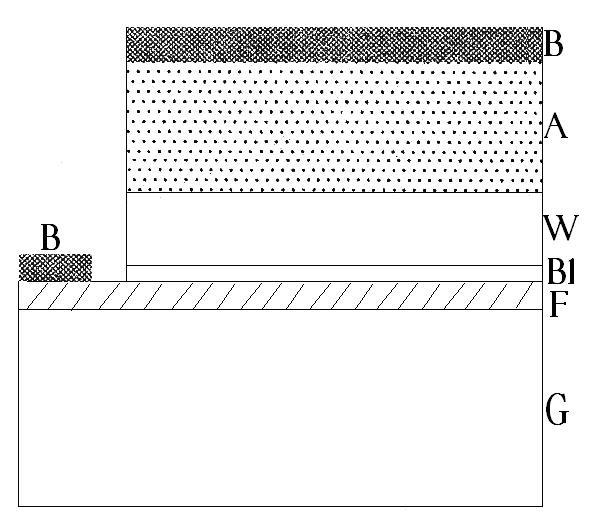

[0023] 1. On borosilicate glass (G), a commercial hot-pressed oxide target (SnO 2 : ~33 mol%, CdO: ~67%), the preparation of Cd 2 SnO 4 (F) Conductive layer. Sputtering conditions: background vacuum ~10 -5 Pa, the working atmosphere is 99.993% pure oxygen, the working pressure is 1-2 Pa, the distance between the target and the sample is 6-9 cm, the sputtering power is 100-600 W, and the sputtering thickness is 100-500 nm. After sputtering, the sample was taken out and placed in a CdS / Ar atmosphere at 580 0 C ~660 0 C heat treatment for 10~30 minutes.

[0024] 2. At room temperature, a commercial hot-pressed oxide target (SnO 2 : ~33 mol%, ZnO: ~67%), to prepare Zn 2 SnO 4 (B1). Sputtering conditions: background vacuum ~10 -5 Pa, the working atmosphere is 99.993% pure oxygen, the working pressure is 1~2 Pa, the distance between the target and the sample is 6~9 cm, the sputtering power is 100~600W, and the sputtering thickness is 70~300 nm.

[0025] 3. Take out str...

Embodiment 2

[0030] 1. On borosilicate glass (G), a commercial hot-pressed oxide target (SnO 2 : ~33 mol%, CdO: ~67%), the preparation of Cd 2 SnO 4 (F) Conductive layer. Sputtering conditions: background vacuum ~10 -5 Pa, the working atmosphere is 99.993% pure oxygen, the working pressure is 1-2 Pa, the distance between the target and the sample is 6-9 cm, the sputtering power is 100-600 W, and the sputtering thickness is 100-500 nm. After sputtering, the sample was taken out and placed in a CdS / Ar atmosphere at 580 0 C ~660 0 C heat treatment for 10~30 minutes.

[0031] 2. At room temperature, a commercial hot-pressed oxide target (SnO 2 : ~33 mol%, ZnO: ~67%), to prepare Zn 2 SnO 4 (B1). Sputtering conditions: background vacuum ~10 -5 Pa, the working atmosphere is 99.993% pure oxygen, the working pressure is 1-2 Pa, the distance between the target and the sample is 6-9 cm, the sputtering power is 100-600 W, and the sputtering thickness is 70-300 nm.

[0032] 3. Take out st...

Embodiment 3

[0037] Change the in-situ post-treatment in step 5 in embodiment one or embodiment two to non-in-situ post-treatment, that is, the sample is taken out, and under the protection of nitrogen or inert gas, heat treatment for 250 0 C ~400 0 C, the time is 10-30 minutes. The other steps are the same as in the first or second embodiment, and a cadmium sulfide homojunction solar cell can also be produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com