Preparation method of lithium ion battery cathode material nano lithium iron phosphate

A technology for lithium ferrous phosphate and lithium-ion batteries, which is applied to battery electrodes, circuits, electrical components, etc., and can solve the problems of product purity, difficulty in controlling crystal morphology and particle size, difficulty in mixing uniform reactants, and large differences in electrochemical performance, etc. problems, to achieve high product quality consistency, facilitate large-scale production, and shorten the ball milling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

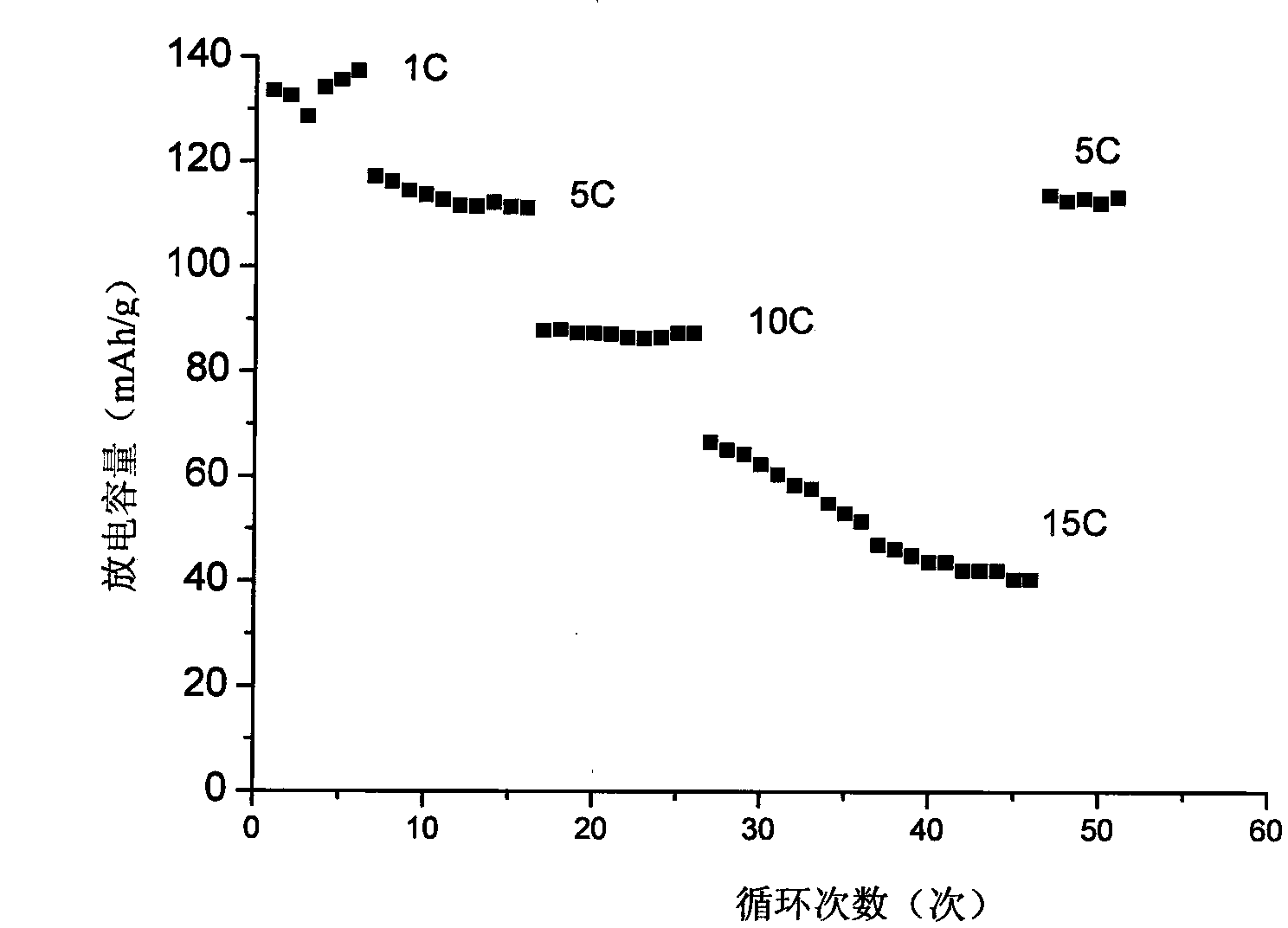

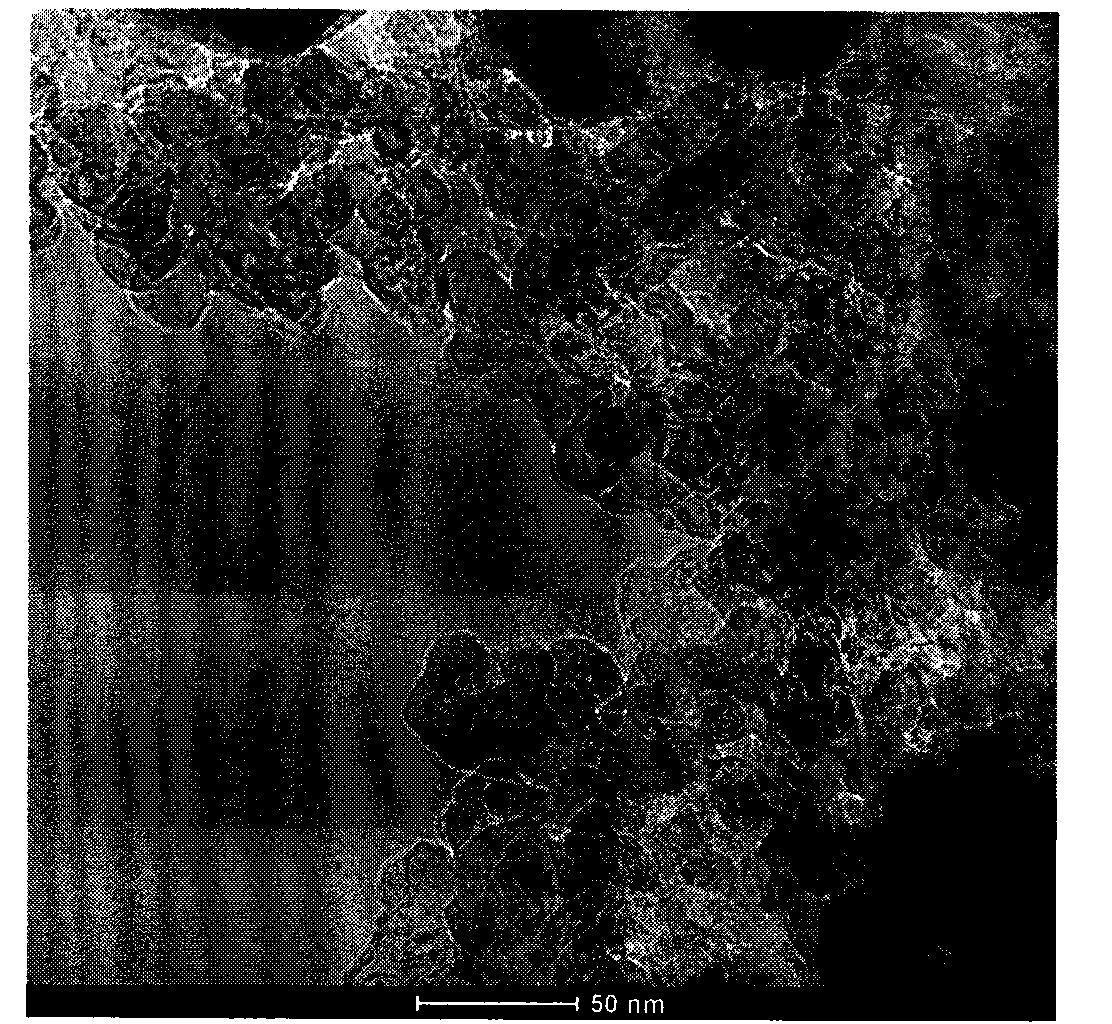

Examples

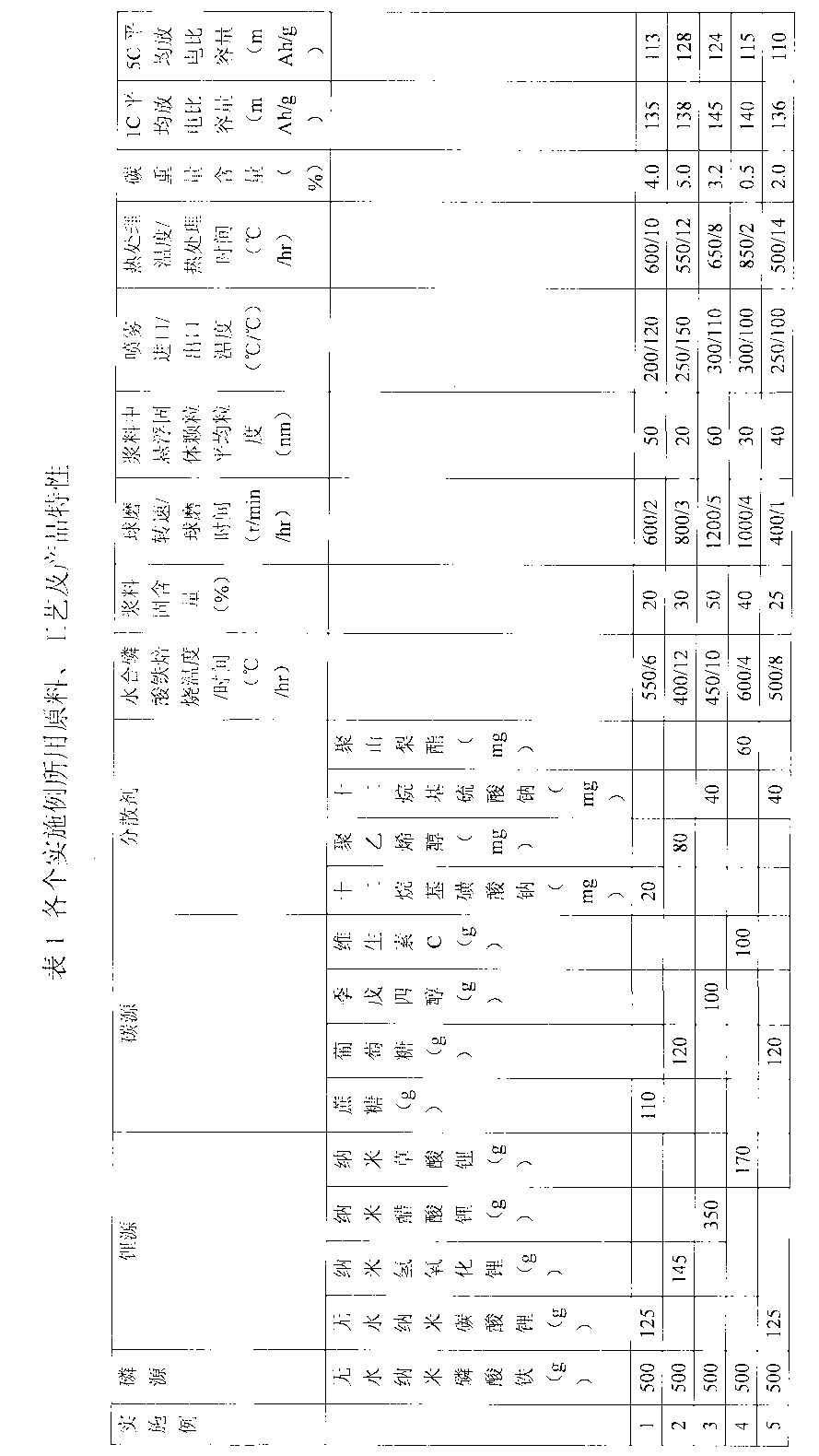

Embodiment 1

[0034] The preparation of lithium iron phosphate nanometer lithium ion battery cathode material is carried out according to the following steps:

[0035] (1) Using lithium hydroxide and sodium carbonate as raw materials, using a rotating packed bed method to prepare nanometer lithium carbonate, the average particle size of the obtained lithium carbonate is 60 nm;

[0036] (2) Ferric nitrate, phosphoric acid and ammonia are used as raw materials to prepare nano-hydrated iron phosphate by the rotating packed bed method. For details, please refer to the applicant’s patent "A method for preparing nano-iron phosphate" (application number: 200910235404.8). The average particle size of nano-hydrated iron phosphate is 40nm;

[0037] (3) Take 620g of FePO nano-hydrated iron phosphate prepared in step (2) 4 ·2H 2 O, in an air atmosphere, the temperature is increased to 550°C at a heating rate of 4°C / min, and roasted for 6 hours to dehydrate to obtain anhydrous nano iron phosphate powder;

[003...

Embodiment 2

[0044] The preparation of lithium iron phosphate nanometer lithium ion battery cathode material is carried out according to the following steps:

[0045] (1) Using iron acetate, phosphoric acid and potassium hydroxide as raw materials, the rotating packed bed method is used to prepare nano-hydrated iron phosphate. For details, please refer to the applicant’s patent "A method for preparing nano-iron phosphate" (application number: 200910235404.8). The average particle size of the obtained nano-hydrated iron phosphate is 20nm;

[0046] (2) Take 620g of FePO nano-hydrated iron phosphate prepared in step (1) 4 ·2H 2 O, roasted at 400°C for 12 hr to dehydrate to obtain anhydrous nano iron phosphate powder;

[0047] (3) Weigh 120g glucose, 500g anhydrous nano iron phosphate and 145g lithium hydroxide with an average particle size of 20nm (molar ratio Li:C:Fe=1.04:1.2:1), add 2000ml water, 80mg polyvinyl alcohol, In the basket ball mill, the ball mill was mixed for 3 hours, and the ball mi...

Embodiment 3

[0053] The preparation of lithium iron phosphate nanometer lithium ion battery cathode material is carried out according to the following steps:

[0054] (1) Using ferric chloride, ammonium dihydrogen phosphate and ammonia as raw materials, the rotating packed bed method is used to prepare nano-hydrated iron phosphate. For details, please refer to the applicant’s patent "A method for preparing nano-iron phosphate" (application number: 200910235404.8 ), the average particle size of the obtained nano-hydrated iron phosphate is 50nm;

[0055] (2) Take 620g of FePO nano-hydrated iron phosphate prepared in step (1) 4 ·2H 2 O, roasted at 450°C for 10 hr in an air atmosphere to obtain anhydrous nano iron phosphate powder;

[0056] (3) Weigh 100g pentaerythritol, 500g anhydrous nano-iron phosphate and 350g nano-lithium acetate (Li:C:Fe=1.04:1.11:1) with an average particle size of 60nm, add 1000ml of water, and add 40mg of sodium lauryl sulfate , Ball milling and mixing in a basket ball mil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com