Preparation of visible light response titanium base film and method for degrading binary dye

A visible light and thin film technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems that have not been reasonably and effectively introduced into the field of preparation and application of visible light-responsive thin film materials, and achieve remarkable results Visible light response characteristics, high-efficiency visible light photocatalytic performance, simple and easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

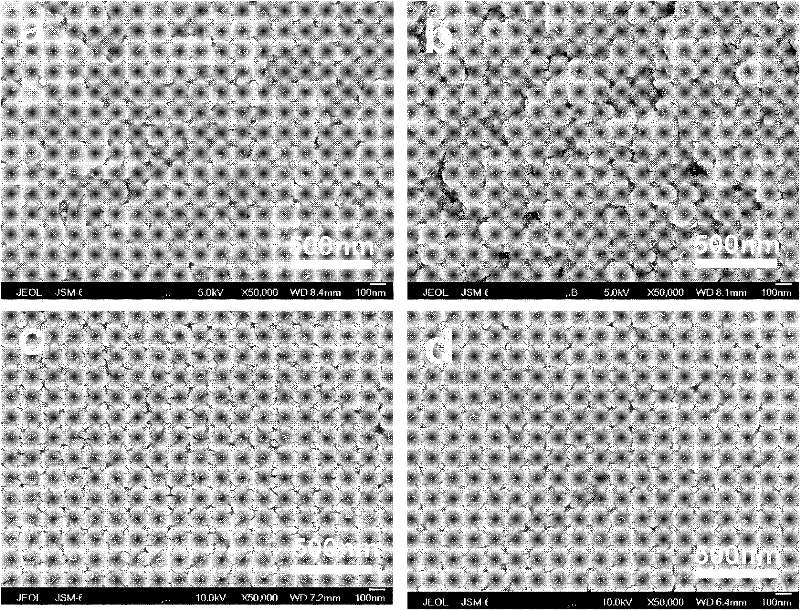

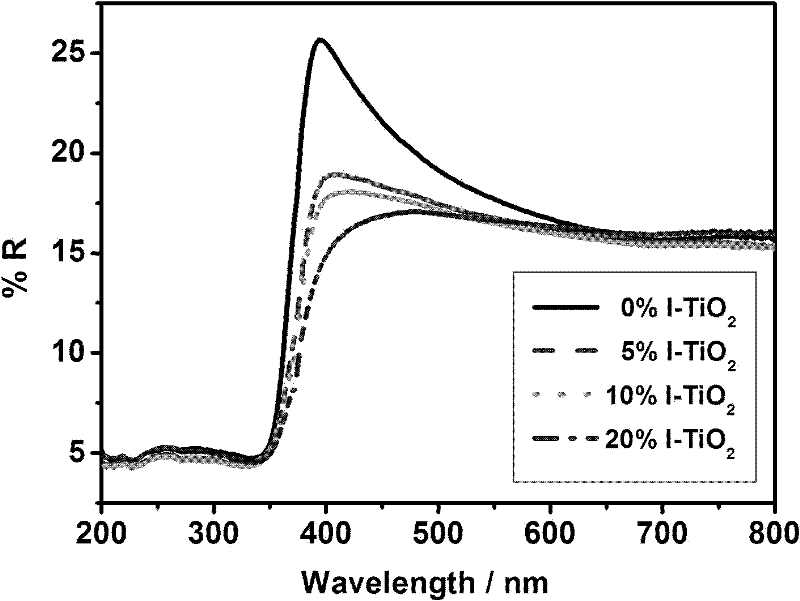

[0030] Measure 22.104ml (21.22g) of titanium tetraisopropoxide into a 100ml Erlenmeyer flask, add 4.136ml (4.34g) of acetic acid dropwise, and magnetically stir at room temperature for 15 minutes. Then quickly pour this mixture into a 250ml three-necked flask equipped with 105ml of water. A certain amount of iodic acid was dissolved in the flask in advance, and vigorously stirred under strong mechanical stirring. After stirring for 1 hour, 1.96 ml of nitric acid with a mass content of 65% was added, and the mixture was heated from room temperature to 50° C. in a water bath within 40 minutes, and solified at this temperature for 75 (out of range) minutes. After solization, add water to lower the temperature of the mixture, and adjust the volume to 134ml. Put the mixed solution in a polytetrafluoroethylene hydrothermal kettle, and conduct a hydrothermal reaction at 180° C. for 12 hours. Thus prepared iodine-doped TiO 2 nanocrystal.

[0031]Or measure 22.104ml (21.22g) of tetr...

Embodiment 2

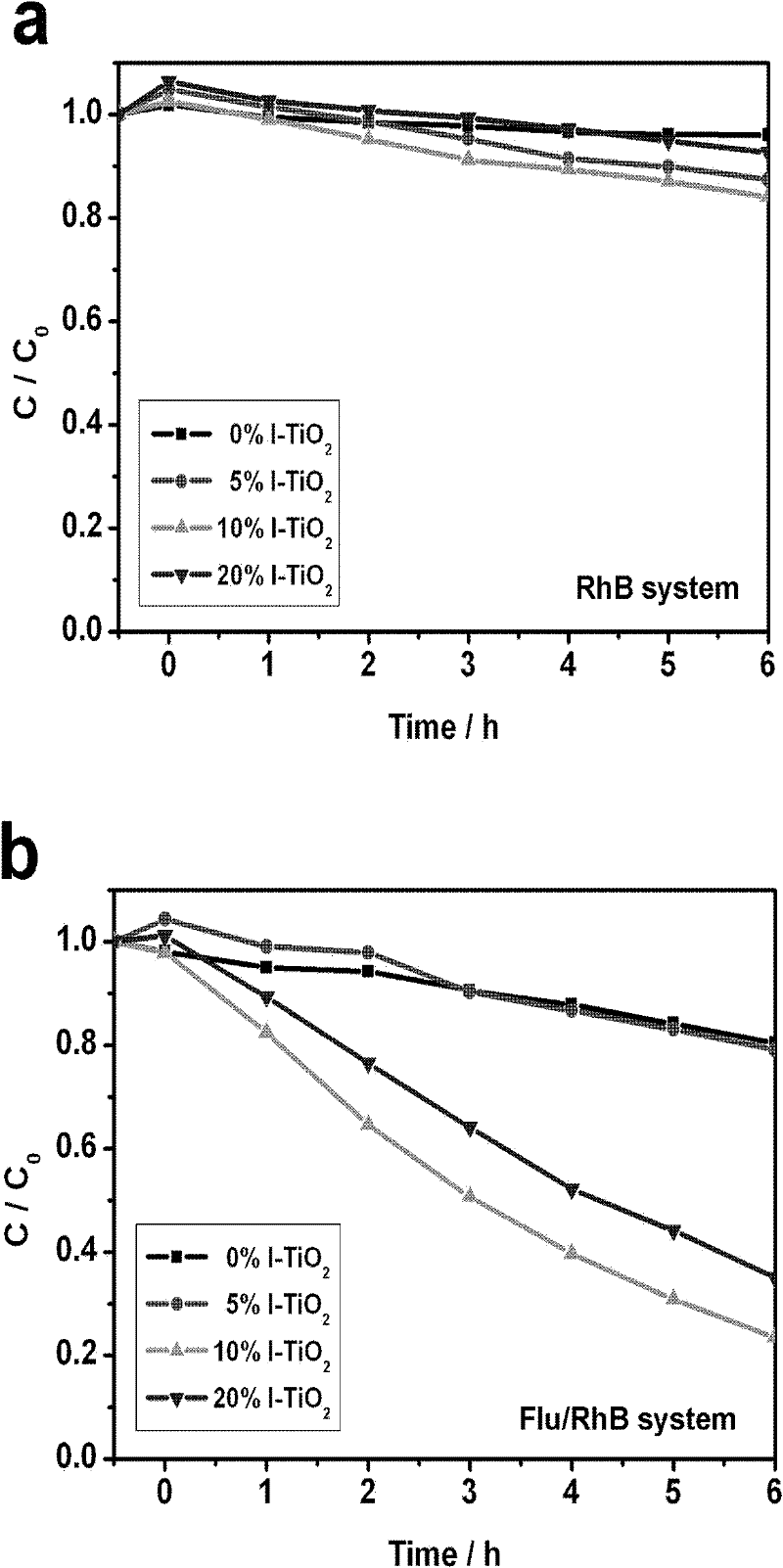

[0038] TiO with different iodine doping 2 The nanocrystalline film was dipped in 40ml Flu / RhB initial solution and 40ml RhB initial solution respectively, the RhB concentration in the initial solution was 2mg / L, and the Flu concentration was 7mg / L. Visible light (above 400nm) is obtained by a halogen lamp equipped with a 420nm filter. Before light exposure, the solution was magnetically stirred for half an hour in the dark to achieve dye adsorption equilibrium on the film surface. The entire reaction device is open, and the solution is always in a state of magnetic stirring when the light is on. After illumination, samples were taken every hour, and the absorbance of the dye at different times was measured by an ultraviolet spectrophotometer, and then the absorbance was converted into concentration, so as to observe the change of RhB concentration over time.

Embodiment 3

[0040] TiO doped with 10% iodine 2 The nanocrystalline thin films were immersed in 40ml EO / RhB initial solution, 40ml RhB initial solution and 40ml EO initial solution respectively. The RhB concentration in the initial solution was 4mg / L, and the EO concentration was 20mg / L. Visible light (above 400nm) is obtained by a halogen lamp equipped with a 420nm filter. Before light exposure, the solution was magnetically stirred for half an hour in the dark to achieve dye adsorption equilibrium on the film surface. The entire reaction device is open, and the solution is always in a state of magnetic stirring when the light is on. After illumination, samples were taken every hour, and the absorbance of the dye at different times was measured by an ultraviolet spectrophotometer, and then the absorbance was converted into concentration, so as to observe the change of the dye concentration over time.

[0041] like image 3 , it can be seen that the iodine-doped TiO 2 The photocatalyti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com