Modified coconut tree branny culture substrate and preparing method thereof

A technology of cultivation substrate and coconut peat, which is applied in the field of preparation of modified coconut peat cultivation substrate, can solve the problems of coconut peat fiber not up to the use standard, high investment in mechanical equipment, and large environmental pollution, so as to promote rapid and efficient circulation Utilization, short time-consuming, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

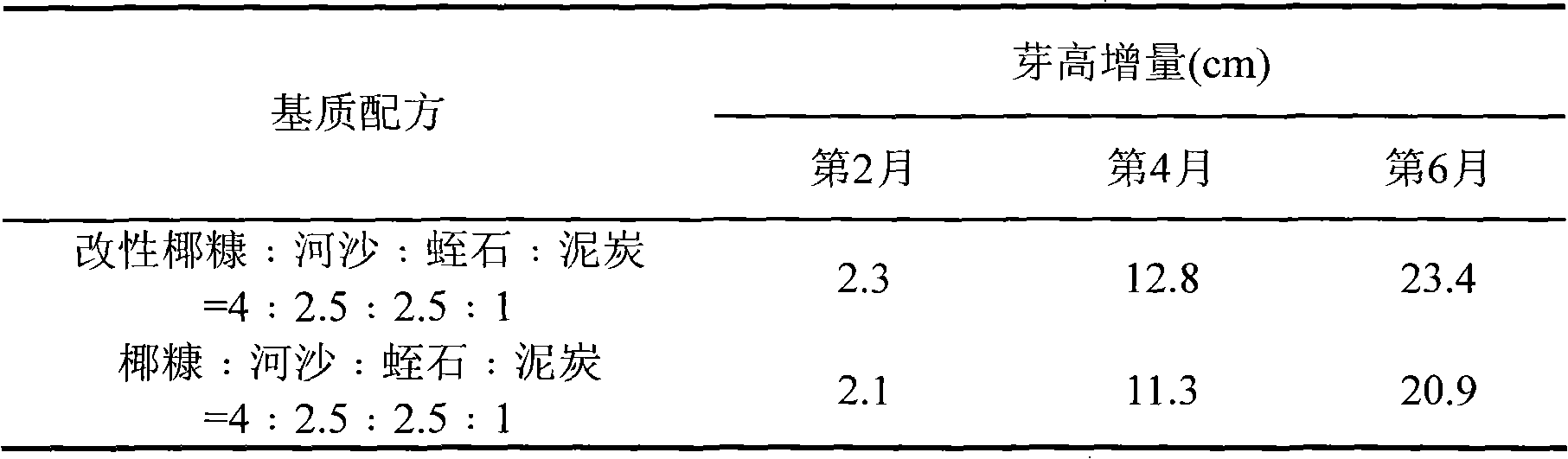

Embodiment 1

[0030] 1. Raw material pretreatment Dried coconut peat at 60°C, crushed, and sieved to make a material with a length of 4-7mm; at the same time, spread out the river sand, sterilize it in the sun for 6 hours, and pass through a 20-mesh sieve; another option is 883Fr2 type Peat (white block, pH6.0), 2-4mm vermiculite (milky white), set aside.

[0031] 2. Modification Add clear water to the coconut bran prepared above according to 1:30 (m / v), so that the coconut bran is completely immersed in water, stir evenly, and swell for 2 hours; Add acid cellulase (10000IU / g) in proportion, adjust pH to 4.5 with sulfuric acid, enzymolyze for 32 hours, stir once every 2 hours during enzymolysis; then add hemifiber according to the ratio of enzyme activity to coconut bran weight ratio of 24IU / g Sulfase (8000IU / g), enzymatic hydrolysis for 8 hours; then add sodium carbonate to adjust the pH to 8.0-9.0, raise the temperature to 70°C, keep for 3 hours to inactivate the enzyme, and obtain the cr...

Embodiment 2

[0041] 1. Raw material pretreatment Dry coconut peat at 50°C, crush, and sieve to make a material with a length of 4-6mm; at the same time, sieve, sun-dry, and sterilize perlite (with a particle size of 8-12mm); peat ( brownish yellow, pH5.6), for later use.

[0042] 2. Modification Add clear water to the coconut bran prepared above according to 1:20 (m / v), so that the coconut bran is completely immersed in water, stir evenly, and swell for 3 hours; Add acid cellulase (10000IU / g) in proportion, adjust the pH to 4.5 with hydrochloric acid, enzymolyze at room temperature for 48 hours, stir once every 3 hours during enzymolysis; then add according to the ratio of enzyme activity to coconut bran weight ratio of 16IU / g Hemicellulase (8000IU / g), enzymatic hydrolysis at room temperature for 12 hours; then add sodium carbonate to adjust the pH to 9.0, raise the temperature to 70°C, keep for 2 hours to inactivate the enzyme, and obtain crude coconut peat enzymatic hydrolysis liquid.

...

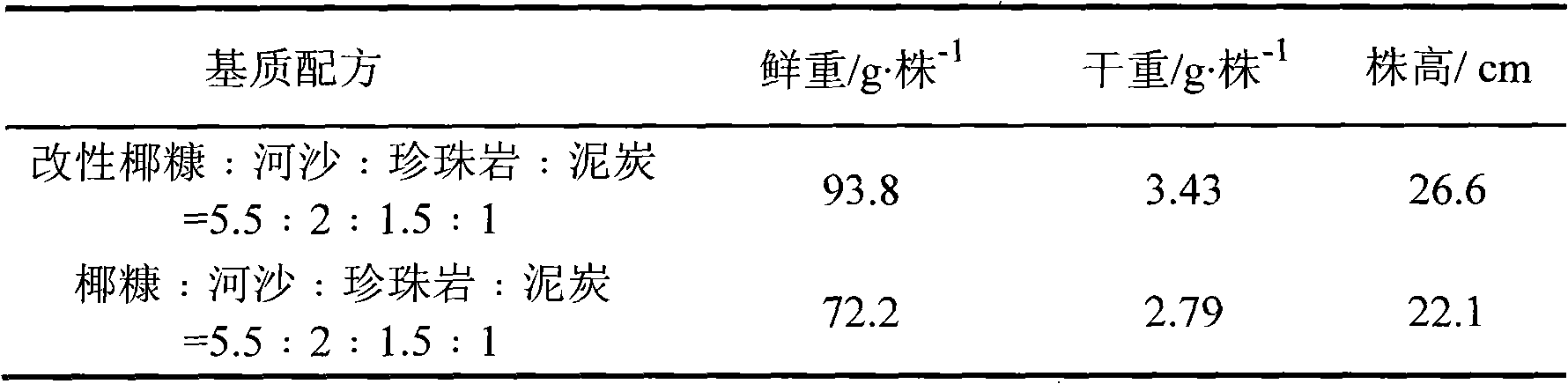

Embodiment 3

[0049] 1. Raw material pretreatment Dry coconut peat at 60°C, crush, and sieve to make a material with a length of 4-6mm; at the same time, spread out the river sand and perlite, sun-dry, sterilize, and sieve; another peat is taken (white block, pH6.0), ready for use after pretreatment.

[0050] 2. Modification Add clear water to the coconut bran prepared above according to 1:40 (m / v), so that the coconut bran is completely immersed in water, stir evenly, and swell for 2 hours; Add acid cellulase (20000IU / g) in proportion, adjust pH to 4.5 with sulfuric acid, enzymolyze for 32 hours, stir once every 2 hours during enzymolysis; Sulfase (8000IU / g), hydrolyze for 12h; then add sodium carbonate to adjust the pH to 8.0-9.0, raise the temperature to 70°C, keep for 3h to inactivate the enzyme, and obtain the crude coconut peat enzymolysis liquid.

[0051] 3. Drying and grading The modified coconut peat can be obtained by filtering, drying, pulverizing and grading the coconut peat en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Enzyme activity | aaaaa | aaaaa |

| Enzyme activity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com