Method for preparing copolymer of dimethyl diallyl ammonium chloride and acrylamide through initiation of composite initiator

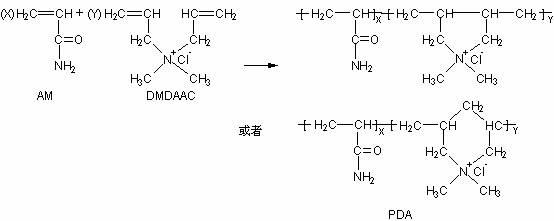

A technology of dimethyl diallyl ammonium chloride and acrylamide copolymer, which is applied in the field of compound initiator to initiate the preparation of dimethyl diallyl ammonium chloride and acrylamide copolymer, which can solve the problem of inability to resist polymerization inhibition Effect, unstable preparation process and other problems, to achieve the effect of high relative molecular weight of the product, increase the relative molecular weight of the product, and high relative molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: the steps of the method for making dimethyldiallyl ammonium chloride and acrylamide copolymer initiated by composite initiator of the present invention are:

[0028] In the first step, add 0.28kg of high-purity industrial product DMDAAC monomer aqueous solution with a mass fraction of (60±2)% and 1.42kg of AM crystals into a 15L reactor at room temperature (≤30°C), and add them in sequence under nitrogen gas stirring Contains 0.32g tetrasodium edetate (Na 4 EDTA) in 0.1L chelating agent solution, 0.1L low temperature initiator solution containing 0.08g azobisisopropylimidazoline hydrochloride (AIBI) and 0.1L high temperature initiator solution containing 0.81g ammonium persulfate (APS) , add deionized water 7.93kg;

[0029] In the second step, stop stirring, stop nitrogen flow, heat up the reaction system to a polymerization temperature of 46±2°C, and react for 4 hours;

[0030] The third step is to heat up the reaction system to a polymerization tempera...

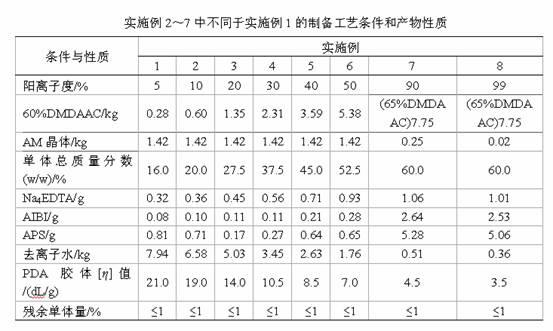

Embodiment 2~7

[0033] Embodiments 2-7: Except that the preparation process conditions and results different from Embodiment 1 are listed in the following table, all the other steps are the same as Embodiment 1.

[0034]

Embodiment 9

[0035] Embodiment 9: The steps of the method for the composite initiator of the present invention to initiate the preparation of dimethyl diallyl ammonium chloride and acrylamide copolymer are:

[0036]In the first step, add 1.35kg of high-purity industrial product DMDAAC monomer aqueous solution with a mass fraction of (60±2)% and 1.42kg of AM crystals into a 15L reactor at room temperature (≤30°C), and add them in sequence under nitrogen gas stirring Contains 0.45g tetrasodium edetate (Na 4 0.1L chelating agent solution containing EDTA), 0.1L low-temperature initiator solution containing 0.11g azobisisopropylimidazoline hydrochloride (AIBI) and 0.1L high-temperature initiator solution containing 0.11g ammonium persulfate (APS) , add deionized water 5.03kg;

[0037] In the second step, stop stirring, stop nitrogen flow, heat up the reaction system to a polymerization temperature of 46±2°C, and react for 4 hours;

[0038] The third step is to heat up the reaction system to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com