Method for treating printing and dyeing wastewater with rare earth cerium doped titanium-based manganese dioxide electrode

A technology of manganese dioxide electrode and printing and dyeing wastewater, which is applied in the field of materials, can solve the problems of long treatment cycle and low treatment efficiency, and achieve the effects of less secondary pollution, high removal efficiency and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

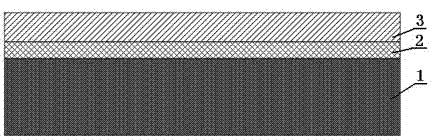

[0040] The preparation of titanium-based manganese dioxide electrode (abbreviated as TSM-5 electrode) doped with 5% cerium concentration includes the following steps:

[0041] (1), pretreatment of titanium substrate

[0042] That is, use 200#, 600#, 1200#, 1500# metallographic sandpaper to polish the surface of the titanium substrate in sequence until it is smooth and smooth, then use saturated sodium hydroxide solution to boil for 30 minutes for degreasing treatment, and then use 1:1 nitric acid + Soak in sulfuric acid for 2 hours, then acid-etch in 10% oxalic acid solution for about 25 minutes, wait until the reddish-brown substance appears to form a pitted titanium matrix, and finally wash with deionized water and soak in absolute ethanol;

[0043] (2) Preparation of tin antimony oxide intermediate layer

[0044] Take SnCl 4 ·5H 2 O0.85g, SbCl 3 0.15g, HCl (36%) 1mL, n-butanol 4ml to prepare the middle layer coating solution, brush the coating solution evenly on the su...

Embodiment 2

[0048] The preparation of titanium-based manganese dioxide electrode (abbreviated as TSM-10 electrode) doped with 10% cerium concentration includes the following steps:

[0049] (1), pretreatment of titanium substrate (same as Example 1);

[0050] (2), preparation of tin antimony oxide intermediate layer (same as embodiment 1);

[0051] (3) Preparation of rare earth element doped manganese dioxide surface coating

[0052] Using 50wt% Mn (NO 3 ) 2 Solution, according to the molar ratio of manganese and cerium of 25:1, add cerium nitrate, dilute with distilled water to prepare 1mol dm -3 Use a brush to evenly coat the surface layer coating solution on the electrode surface with the prepared intermediate layer, dry it at 90°C for 10 minutes, and then thermally decompose it at 200°C for 5 minutes. This process is repeated 30 times , and finally sintered at 350° C. for 20 minutes to finally obtain the TSM-10 electrode of the present invention, the surface coating thickness of whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com