Monodisperse surface functionalized polymer microsphere resin and preparation method thereof

A surface functionalization, monodisperse technology, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of uncontrollability and controllability of the surface grafting process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

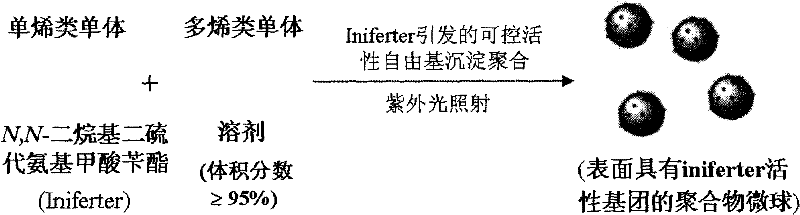

Method used

Image

Examples

example 1

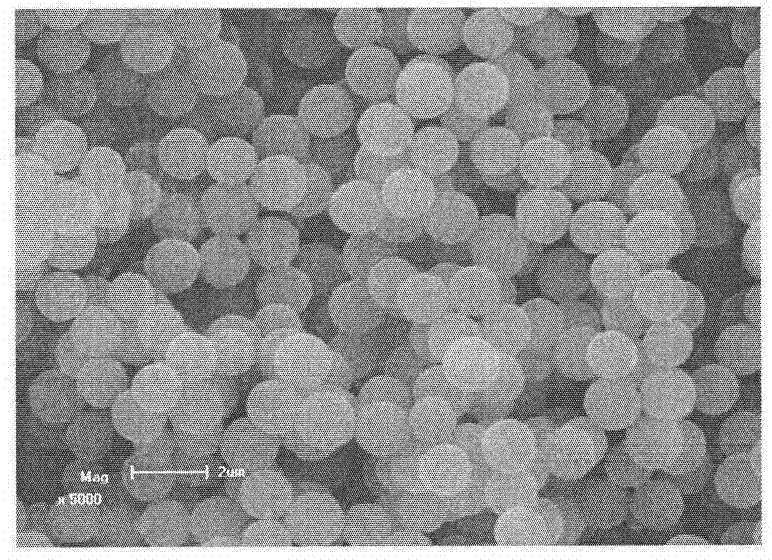

[0024] Example 1: Add 0.47mL EGDMA, 27.3mg N,N-benzyl diethyldithiocarbamate (BDC) and 30mL acetonitrile in sequence into a 100mL round bottom flask, and stir it with a magnet to dissolve it completely. After deoxygenating with argon gas for 30 minutes, the reaction system was sealed, and reacted for 10 hours under the irradiation of a high-pressure mercury lamp (the distance between the reaction bottle and the lamp was 10 cm, and the reaction temperature was 26° C.). After the reaction, the reaction system was subjected to ultracentrifugation (10000 r / min), and the obtained polymer microspheres were washed 4 times with methanol, and then vacuum-dried at 40° C. to constant weight (yield 31%).

[0025] The scanning electron micrographs of the obtained polymer microspheres are shown in figure 2 (number average diameter D n =1.35μm, weight average diameter D w =1.37 μm, particle size polydispersity index U=1.015).

example 2

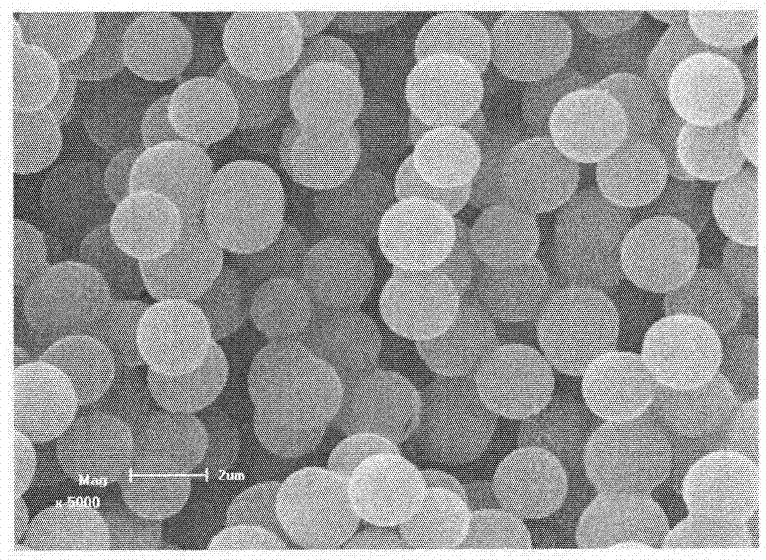

[0026] Example 2: Add 0.47mL of EGDMA, 27.3mg of BDC and 15mL of acetonitrile into a 100mL round bottom flask in sequence, and stir it with a magnet to dissolve it completely. After deoxygenating with argon gas for 30 minutes, the reaction system was sealed, and reacted for 10 hours under the irradiation of a high-pressure mercury lamp (the distance between the reaction bottle and the lamp was 10 cm, and the reaction temperature was 26° C.). After the reaction, the reaction system was subjected to ultracentrifugation (10000 r / min), and the obtained polymer microspheres were washed 4 times with methanol, and then vacuum-dried at 40° C. to constant weight (yield 46%).

[0027] The scanning electron micrographs of the obtained polymer microspheres are shown in image 3 (D n = 1.98 μm, D w = 2.03 μm, U = 1.025).

example 3

[0028] Example 3: Add 0.47mL of EGDMA, 27.3mg of BDC and 45mL of acetonitrile into a 100mL round bottom flask in sequence, and stir it with a magnet to dissolve it completely. After deoxygenating with argon gas for 30 minutes, the reaction system was sealed, and reacted for 10 hours under the irradiation of a high-pressure mercury lamp (the distance between the reaction bottle and the lamp was 10 cm, and the reaction temperature was 26° C.). After the reaction, the reaction system was subjected to ultracentrifugation (10000 r / min), and the obtained polymer microspheres were washed 4 times with methanol, and then vacuum-dried at 40° C. to constant weight (yield 16%).

[0029] The scanning electron micrographs of the obtained polymer microspheres are shown in Figure 4 (D n = 1.16 μm, D w = 1.19 μm, U = 1.026).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com